Beryllium Powder Vibro Sifter

Introduction of Beryllium Powder Vibro Sifter

Beryllium powder vibro sifter is a vibration sieve for sieving, filtering, and selecting treatment of berylliumpowder. This screen has an efficient, accurate and reliable screening effect, which can meet the requirements of different particles, shapes, density and other requirements. The screening requirements of the beryllium powder.

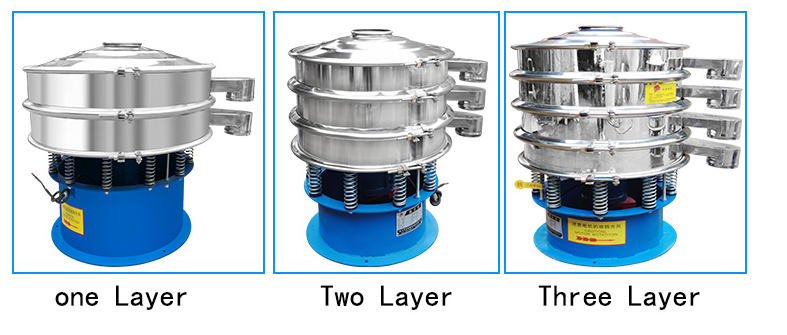

Structures of Beryllium Powder Vibro Sifter

1. Sieve frame: It is usually made of welding, with strong structure, stable support and corrosion resistance.

2. Vibrator: The core part of the vibration screen is composed of motor, motor seat, screen frame and spring. The motor is connected to the sieve frame through the motor seat and the spring, which generates vibration, so that the material has a fierce jitter on the screen surface, thereby achieving the purpose of screening.

3. Screen: The sieve on the vibration sieve is usually composed of pores of different sizes and mesh sieves of different materials. The material and pores of the sieve network are selected according to the characteristics of the material.

4. The disagreement port: The discharge port of the vibration screen can be set on one or both sides as needed to receive the sieving material.

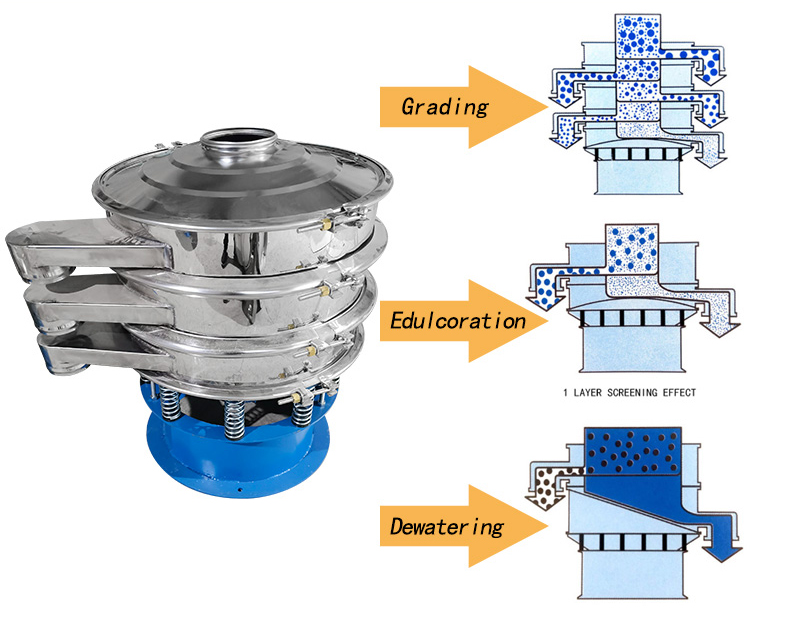

Working Principle ofBeryllium Powder Vibro Sifter

The working principle of beryllium powder vibro sifter is to vibrate the screen frame generated by the vibration generated by the motor, thereby separating the material.

1. The material enters the feed inlet of the vibration sieve and sieves through the screen.

2. The motor vibration causes the screen frame to produce vibration. The material on the screen is thrown above, falling below, and repeating this process.

3. During the screening process, the material is divided into two parts according to the pore diameter of the screen: the material greater than the sieve size is discharged through the material port of the vibration sieve, and the material smaller than the sieve size is fell into the material through the sieve net. mouth.

4. Sievant materials can be collected and used directly, or further treatment.

Features and advantages

1. Efficient: The vibration motor is used as the source of power, the vibration strength is large, and the screening efficiency is high.

2. Precision: The size of the sieve can be adjusted as needed to make the screening result more accurate.

3. Energy -saving: Energy of vibration motor is balanced without excessive vibration and noise, saving energy.

4. Convenience: The structure of the whole machine is compact, easy to operate, and easy to maintain.

5. Strong adaptability: suitable for drying, screening, grading, filtering and other operations of a variety of materials.

Application of Beryllium Powder Vibro Sifter

Beryllium powder vibro sifter is mainly suitable for the screening and filtering of fine powder materials, such as beryllium, metal powder, medicine powder, chemical raw materials and other industries. Specific application scenarios include:

1. Metal powder industry: Siring, grading and filtering metal powder to remove impurities.

2. The pharmaceutical industry: sieve the medicine powder to remove impurities, and realize the monitoring and improvement of product quality.

3. Chemical industry: Siege the chemical raw materials to remove impurities and improve the quality and purity of the powder.

4. Food industry: Siege the fine powder products to remove impurities and ensure the quality and taste of the product.

How to Use Beryllium Powder Vibro Sifter?

1. Prepare operation: Put the beryllium powder vibro sifter on the smooth countertop and connect the power cord and control line.

2. Check: Check whether the screen, the screen frame, and the sieve are in a non -destructive state, and check whether the power cord and the control line are well exposed.

3. Start operation: Put the prepared powder sample in the vibration screen, open the controller switch, and start vibration sieve.

4. Regulating amplitude: According to different screening requirements, adjust the amplitude, and generally there is an amplitude adjustment button on the controller, and the appropriate amplitude size is selected as needed.

5. Observe the screening: After the vibration sieve is turned for a certain period of time, the screening situation is observed. If you need to sieve more detailed, you can replace the screen.

6. Close operation: After the screening is completed, the controller can be turned off and the operation of the beryllium powder vibro sifter can be stopped. Pour the powder samples in the vibration sieve and clean up the screen, screen frame and sieve body.

-

Used for screening, classifying and removing impurities in various powder

-

Suitable for sieving wet and dry materials, this circular vibratory screener can remove oversize and contamination

-

Stainless Steel Vibrating Sieve

The sieving is fine to 500 mesh or 0.028mm, and the sieving accuracy is high.

-

How to Apply Powder Coating Ultrasonic Sieving Machine

Powder coating ultrasonic sieving machine is a fine powder sieving machine with relatively perfect te ...

-

Tantalum Powder Vibro Sifter

Introduction of Tantalum Powder Vibro Sifter Tantalum powder vibro sifter is a device for separation and screening. ...

-

Beryllium Powder Vibro Sifter

Introduction of Beryllium Powder Vibro Sifter Berylliumpowder vibro sifter is a vibration sieve for sieving ...

-

Niobium Powder Vibro Sifter

Introduction of Niobium Powder Vibro Sifter Niobiumpowder vibro sifter is an efficient screening equipment that ...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.