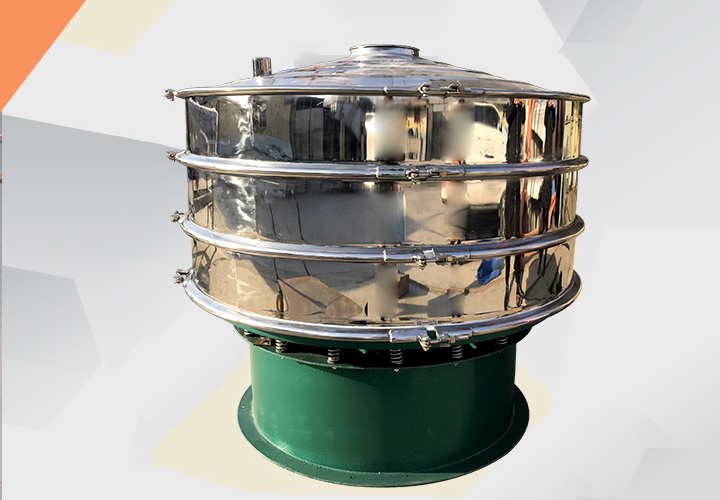

Niobium Powder Vibro Sifter

Introduction of Niobium Powder Vibro Sifter

Niobium powder vibro sifter is an efficient screening equipment that can be used to screen and separate various powder and granular materials.It consists of a vibration motor, sieve, vibrator, vibrating spring, and base.

Working Principle of Niobium Powder Vibro Sifter

The vibration motor transmits the energy to the sieve through a vibrator, so that the sieve can produce high -speed vibration, thereby achieving the screening and separation of the material. The material enters the sieve body from the feast and inlet. Due to the effect of vibration, the material with similar particle size forms an optimized distribution state on the sieve. The large particles are blocked on the screen. Separate the sieve hole, and finally discharge the corresponding mouth.

Features and advantages

1. Niobium powder vibro sifter has high efficiency and high screening accuracy, which can effectively improve production efficiency and screen quality.

2. The screen network adopts a multi -layer structure, which can perform multi -level screening to achieve higher accuracy and screening effect.

3. The screen network has a self -cleaning function, avoiding blocking and stuck, and reducing the stop time and artificial cleaning costs.

4. Simple operation, convenient maintenance, small area, saving the cost of occupation of production venues.

Application of Niobium Powder Vibro Sifter

1. Niobium powder vibro sifter is suitable for dry powder sieve, liquid filtration, rust removal, dust removal, etc., which are widely used in food, chemical, medicine, ceramics, metallurgy, building materials and other industries.

2. It can be used to screen bulk raw materials, such as potassium chromate, ammonium molybdenonate and other materials.

3. It can also be used in fine sieves in the production process, such as power coal screening, quartz sand screening and other fields.

How Does Niobium Powder Vibro SifterWork?

The specific work process is as follows:

1. Material feeding: Enter the vibration screen through the feed inlet to be screened.

2. Vibration Sieving: Vibration motors vibrate the screen frame through the screen frame, and make the material forward straight to make the particles smaller than the sieve holes less than the sieve holes are sieved.

3. Materials: After screening, collect the sieved materials through the materials to achieve the purpose of screening.

4. Cleaning and maintenance: After the vibration is screening, clean and maintain the screen frame to ensure the normal use and maintenance of the equipment.

-

Used for screening, classifying and removing impurities in various powder

-

Suitable for sieving wet and dry materials, this circular vibratory screener can remove oversize and contamination

-

Stainless Steel Vibrating Sieve

The sieving is fine to 500 mesh or 0.028mm, and the sieving accuracy is high.

-

How to Apply Powder Coating Ultrasonic Sieving Machine

Powder coating ultrasonic sieving machine is a fine powder sieving machine with relatively perfect te ...

-

Tantalum Powder Vibro Sifter

Introduction of Tantalum Powder Vibro Sifter Tantalum powder vibro sifter is a device for separation and screening. ...

-

Beryllium Powder Vibro Sifter

Introduction of Beryllium Powder Vibro Sifter Berylliumpowder vibro sifter is a vibration sieve for sieving ...

-

Niobium Powder Vibro Sifter

Introduction of Niobium Powder Vibro Sifter Niobiumpowder vibro sifter is an efficient screening equipment that ...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.