Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials, easy agglomeration, low melting point, easy to generate static electricity, and adhesion to the back of the screen after passing through the screen, causing mesh blockage. It uses airflow to drive particle separation and is equipped with an ultrasonic system to solve problems such as screen blockage and low mesh casting rate.

Advantages of centrifugal screening machine equipment

Equipped with an ultrasonic system, it is more effective in handling difficult-to-screen materials

The screen has strong cleaning ability and high efficiency, which extends the service life of the screen

External energy displacer keeps the material from being contaminated during the screening process

Can crush the agglomerated materials

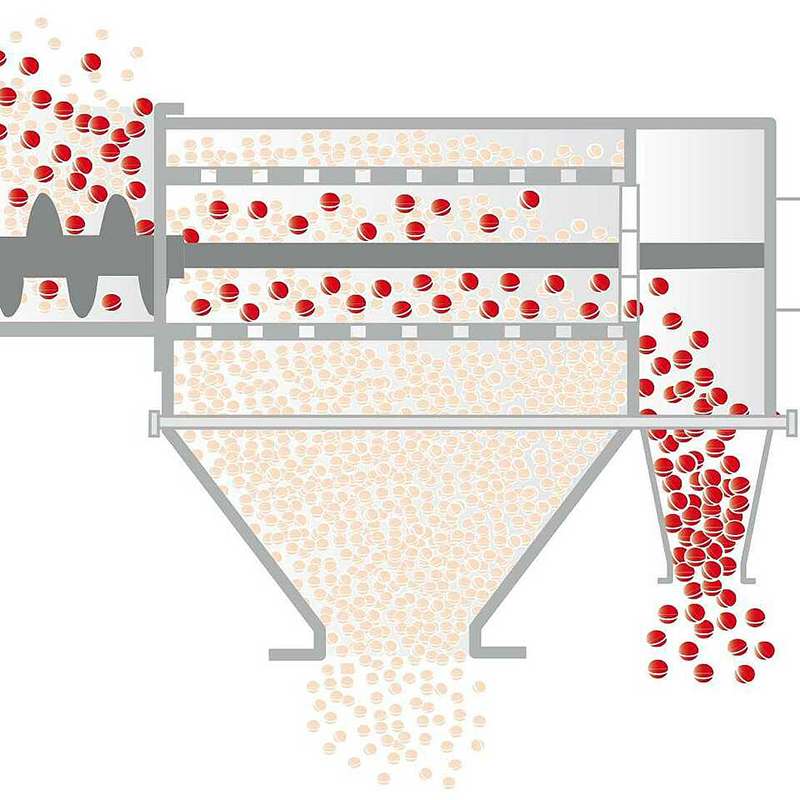

Working principle of centrifugal screening machine

The screen is a cylindrical screen placed in the machine body. The material is mixed with the airflow and atomized through the spiral conveying system and enters the net cylinder. The wind wheel blades in the net cylinder make the material subject to centrifugal force and cyclone propulsion at the same time, so that the material is ejected through the net and discharged from the fine material outlet. The material that cannot pass the net is discharged from the coarse material outlet along the cylinder wall.

Application fields of centrifugal screening machine

It is widely used in the rapid screening of lighter materials or finer powders and ultrafine powders in industries such as chemical industry, metallurgy, mining, pharmaceuticals, food, metal powder and non-metallic industries.

-

Granules, powders, and paddle materials can be used

-

Can sieve ultra-fine powder down to 20 microns without clogging the sieve holes

-

Graphite Powder Sieving Machine

It can be used in single layer or multiple layers, and 6 different grades of graphite ...

-

Konjac fine powder ultrasonic vibrating screen

Konjac fine powder ultrasonic vibrating screen is a high-precision fine particle screening equipment. The equipment uses the up and down excitation force....

-

Paint raw materials sieve with vibro shaker

Paint raw materials sieve with vibro shaker The quality and performance of paint largely depend on the selection and screening of raw materials.....

-

Dietary Supplements for Vibrating Sieve

Dietary supplements vibrating sieve As an efficient and reliable sieving equipment, it plays an important role in the production of dietary supplements. Through high-frequency vibra ...

-

Aqua Feed For Ultrasonic Vibrating Screen

The aquatic feed ultrasonic vibrating screen uses advanced ultrasonic technology to achieve an efficient screening process through high-frequency weak vibration. Compared with tradi ...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.