Chemical liquid vibrating screen

Chemical liquid vibrating screen is a device used for solid-liquid separation or liquid filtration, usually used in the chemical industry to screen, filter or separate solid-liquid mixtures. It intercepts solid impurities in liquid through the vibrating screen to purify the liquid. It is often used in the process of particle material screening, solid-liquid separation and other processes in the chemical production process. In chemical production, the vibrating screen plays a vital role to ensure the purity and quality of the product.

Chemical liquid vibrating screen video

How does the chemical liquid vibrating screen

The vibration generated by the vibrating motor causes the screen box to produce horizontal reciprocating motion or three-dimensional motion. After the chemical liquid and the solid particles in it enter the screen box, under the action of vibration, the chemical liquid flows out through the pores of the screen, while the solid particles are retained on the screen, thus achieving solid-liquid separation.

Advantages of chemical liquid vibrating screen

1. Adapt to complex working conditions: Chemical liquid vibrating screen has good sealing performance to prevent chemical liquid leakage and environmental pollution. Key components are made of corrosion-resistant materials to adapt to corrosive media in chemical liquids.

2. Prevent chemical liquids from clogging the screen: Chemical liquid vibrating screen can effectively prevent solid particles from clogging on the screen through high-frequency vibration, help particles pass through the screen quickly, and maintain screening efficiency.

3. Avoid chemical liquid adhesion: The vibration force of the vibrating screen can reduce the adhesion between particles, keep the particles loose, avoid particles from adhering to the screen, and improve the screening effect.

4. Deal with corrosion: For parts that come into contact with chemical liquids, corrosion-resistant materials are selected to maintain the integrity and performance stability of the equipment under the long-term action of corrosive chemical liquids such as acid and alkaline, and extend the service life of the vibrating screen.

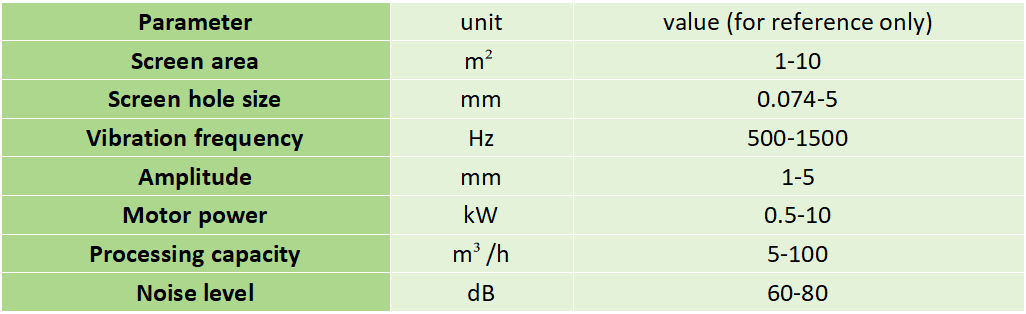

Technical parameters of chemical liquid vibrating screen

Recommended mesh size for chemical liquid vibrating screen

Coarse screening: usually between 20 mesh and 60 mesh. Suitable for screening larger particles, used for preliminary screening and removal of large particle impurities.

Medium screening: usually between 80 mesh and 120 mesh. Suitable for screening medium-sized particles, used for screening of general particles.

Fine screening: usually above 150 mesh. Suitable for screening of fine particles, used in occasions requiring high-precision screening.

Application of chemical liquid vibrating screen

1. Pretreatment of chemical raw materials: In the chemical production process, many raw materials contain impurities, such as sand, gravel, iron filings, etc. Through the vibrating screen, these impurities can be effectively removed to ensure the purity of the raw materials. Raw materials of different particle sizes are graded to meet the requirements of different processes.

2. Purification of intermediate products: In the chemical reaction process, solid precipitation often occurs. The vibrating screen can be used to separate the solid precipitation from the liquid to obtain a pure liquid product. Impurities generated during the production process can be filtered through the vibrating screen to avoid affecting subsequent processes.

3. Fine processing of finished products: The products are graded according to the particle size to meet the needs of different customers. Ensure that the product does not contain impurities and improve product quality.

4. Waste liquid treatment: The chemical liquid vibrating screen can effectively separate solid waste from liquid and reduce the difficulty of waste liquid treatment.

Chemical liquid vibrating screen is a solid-liquid separation equipment, which is widely used in chemical, food, pharmaceutical and other fields. By rationally selecting and using liquid vibrating screen, the purity of the product can be improved and the product quality can be improved.

-

Screening and filtering of particles, powders, liquids and other materials

-

Filter wheat flour and remove unwanted particles to ensure product quality

-

Plastic particle vibrating screen

Titanium powder vibrating screen is a device specially used for screening titanium powder. It...

-

Bread Flour Vibrating Screen

Bread flour vibrating screen is a special equipment for screening bread flour. In the production process...

-

Paint vibrating screen

Corn starch vibrating screen is a specialized piece of equipment used for screening corn starch. It uses...

-

Popcorn vibrating screen

Popcorn vibrating screen is a screening equipment specially designed for the popcorn processing industry. It...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.