Chocolate Vibrating Sieve

Callback

| Model | DH400-DH2000 |

| Capacity | 100-3300kg/h |

It is suitable for sieving from 36 microns to 25 mm.

Mirror polished with a 0.1-0.2 RA internal and external surface finish, ensuring no material deposits and zero chance of material contamination

Closed system eliminates airborne dust problems

Introduction of chocolate vibrating sieve

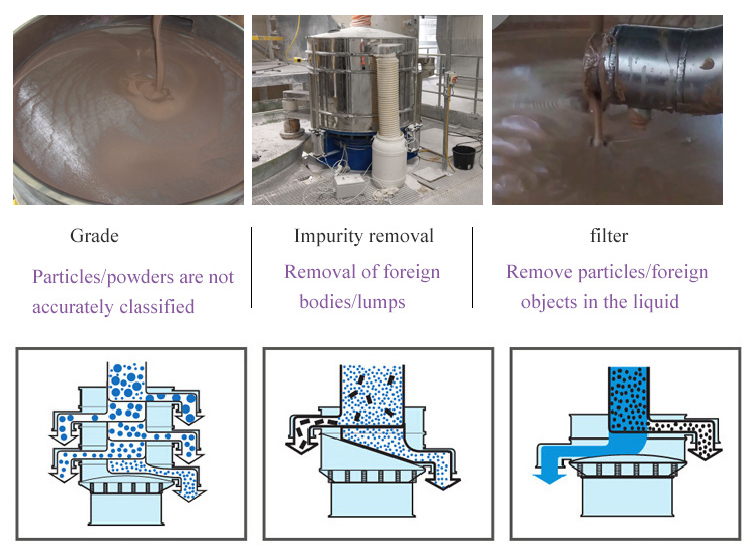

Chocolate vibrating sieve is often used in food factories to make a variety of foods. Sometimes it is necessary to use vibrating sieve to filter the chocolate syrup or coffee powder, so as to prevent impurities from affecting the quality of the food. Chocolate vibrating sieve removes oversized contaminants from both virgin and reclaimed chocolate, it is an ideal solution for high volume liquid filtration, and thanks to its closed system, it provides a contamination-free product down to 15 microns or more.

Through the return visits of old customers who purchased vibrating sieve to filter chocolate syrup or coffee powder, it was found that most of the users reported that using vibrating sieve to filter chocolate syrup or coffee powder is very effective. Using 80 or 100 mesh screen, the output can reach 500-600 kg per hour.

Application of chocolate vibrating sieve

1.Chocolate beans:The chocolate vibrating sieve removes branches, stones and other debris from the coffee beans, and at the same time, you can complete the particle size classification of the chocolate by installing 1-5 layers of sieves during the sieving process, you can obtain in one operation 2-6 different levels.

2.Chocolate powder:Cocoa nibs are milled in a grinder to produce fine chocolate powder. Using chocolate vibrating sieve can remove oversized materials and debris from chocolate powder and improve the quality of the product so that it is not affected in terms of taste and consumer health.

3.Chocolate slurry:It is used to filter the impurities and agglomerates in the chocolate syrup, which can realize continuous operation.

Working principle of chocolate vibrating sieve

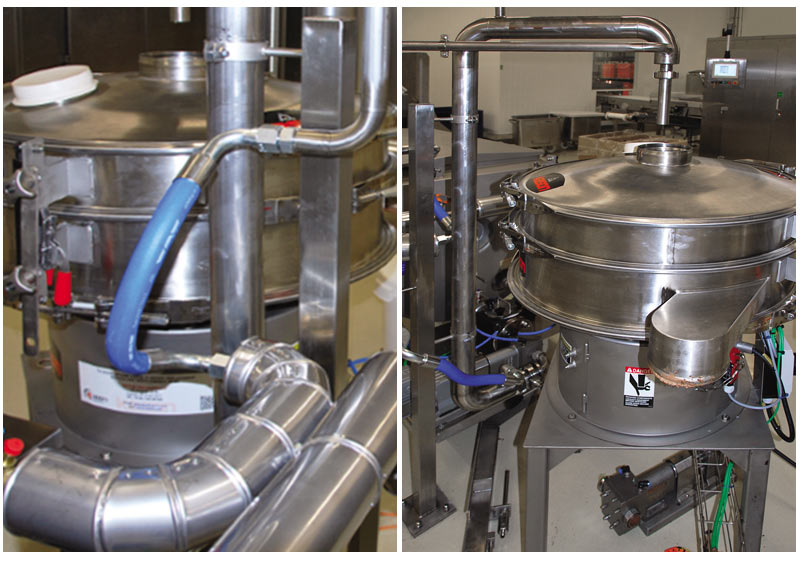

Chocolate bars may be the wrong size or shape, cracked or damaged, or improperly packaged. Every time a production or packaging line is restarted, the first bars on the line must also be reworked. Rejected chocolate bars are ground into pieces and heated in containers to 50°C (122°F) to melt the chocolate without burning, caramelizing or crystallizing. In two lines, the mixture of melted chocolate and solid particles is fed through double-walled pipes to the central inlet of a sifter dedicated to dark chocolate or another dedicated to white chocolate. Unbalanced weight rotary motors generate multi-plane inertial vibrations that accelerate the flow of melted chocolate through the 1020 µm (17 mesh) apertures in the screen and solid particles through the screen and out through the outlet at the edge of the screen peripheral. The melted chocolate passes through the sieve in less than a minute and cools no more than 0.5°C (0.9ºF), preventing it from setting. Vibration starts automatically when the pump feeds the screen and runs for a preset time after the pump stops. Each screen can handle 150 kg (330 lbs) per hour.

Featured Videos

-

chocolate vibrating sieve for sieving chocolate beans

-

chocolate vibrating sieve for filter chocolate slurry

Benefits of chocolate vibrating sieve

1.It is suitable for sieving from 36 microns to 25 mm.

2.It permits a production volume of 100 to 5,000 kg/h, depending on the product, the mesh opening size and the feed flow to the machine.

3.Chocolate vibrating sieve allows up to 4 sieves, with which up to 5 product separations are obtained.

4. Made of SS 304 and 316L stainless steel with 0.1-0.2 RA internal and external surface finish, mirror finish makes cleaning of the machine very easy and helps to audit material deposits.

5. Fully enclosed structure ensures dust-free operation and leak-proof system, all welded joints are seamless, providing hygienic and pollution-free operation.

6. Provide installation casters, which can be easily moved in the factory when needed.

Technical parameters of chocolate vibrating sieve

Chocolate vibrating sieve is available in a variety of models (from Ø 400 to Ø 2200 mm) to meet any type of requirement. On each vibrating sieve, you can install 1 to 4 separation stages, resulting in 2 to 5 product gradings.

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

Related case

Through the return visits of old customers who purchased vibrating sieve to filter chocolate pulp or coffee powder, it was found that most users reported that using vibrating sieve to filter chocolate pulp or coffee powder was very effective. Using 80 or 100 mesh screens, the output can reach 500-600 kg per hour.

-

The screen is fine to 500 meshes, and it is not easy to be blocked.

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.