Concrete vibrating screen

Concrete vibrating screen is a screening equipment used in concrete production. It is mainly used to screen, grade and remove impurities from concrete particles. Its main function is to separate aggregates such as sand and gravel in concrete according to particle size through vibration to ensure the uniformity and cleanliness of aggregates, thereby improving the quality and performance of concrete, and achieving the purpose of improving the density of concrete and increasing its strength and durability.

Concrete vibrating screen video

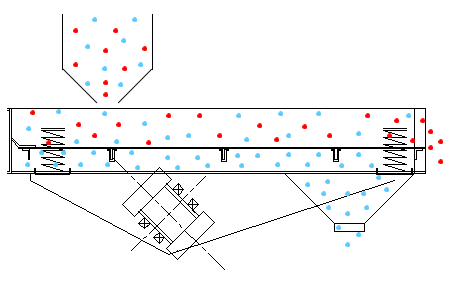

How does Concrete vibrating screen work

Concrete vibrating screen makes the screen box produce horizontal reciprocating motion or three-dimensional motion by means of vibration. The aggregate in the concrete is subjected to the combined action of the exciting force and gravity on the screen surface, producing jumping motion. The particles smaller than the screen hole pass through the screen, while the particles larger than the screen hole are retained on the screen surface, thus achieving screening.

What is the purpose of a concrete vibrating screen?

1. Screening concrete aggregates: Classify aggregates such as sand and gravel according to particle size to ensure that the aggregates meet the requirements of concrete mix ratio.

2. Remove impurities: Screen out impurities such as soil and debris in the aggregates to improve the cleanliness of the aggregates.

3. Recycled concrete processing: Screen the recycled aggregates after the waste concrete is crushed to separate the reusable parts.

4. Optimize the concrete mix ratio: Aggregates of different particle sizes are obtained through screening, which is convenient for precise control of the concrete mix ratio.

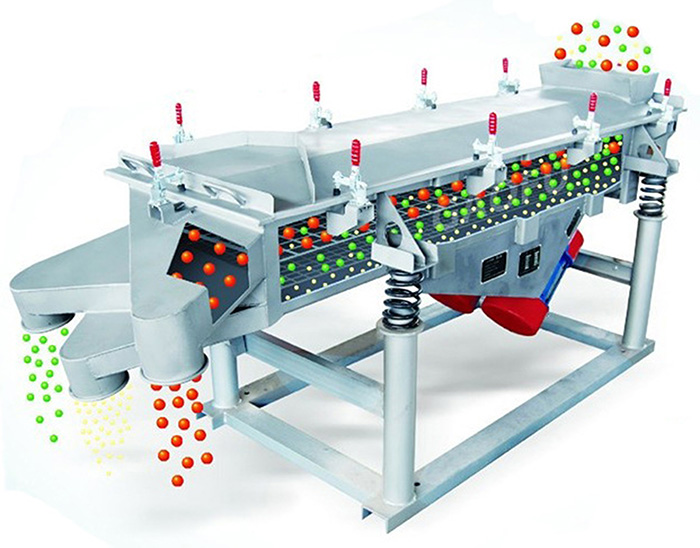

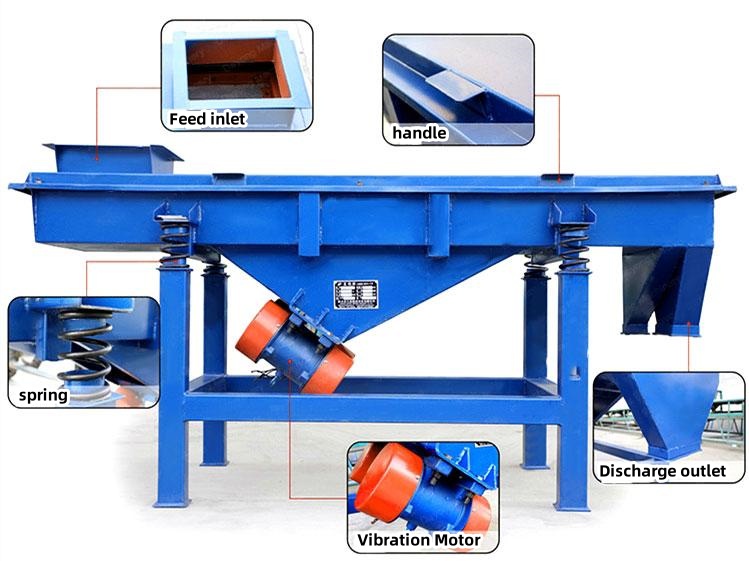

The structure of concrete vibrating screen

The structure of concrete vibrating screen includes screen box, screen mesh, vibration motor, shock absorber, base, feed port, discharge port, support frame, control system, sealing device and cleaning device. These components work together to ensure that the vibrating screen can efficiently and stably complete the screening task of concrete aggregate. Its structural design focuses on strength, stability and durability, and can adapt to various complex screening needs.

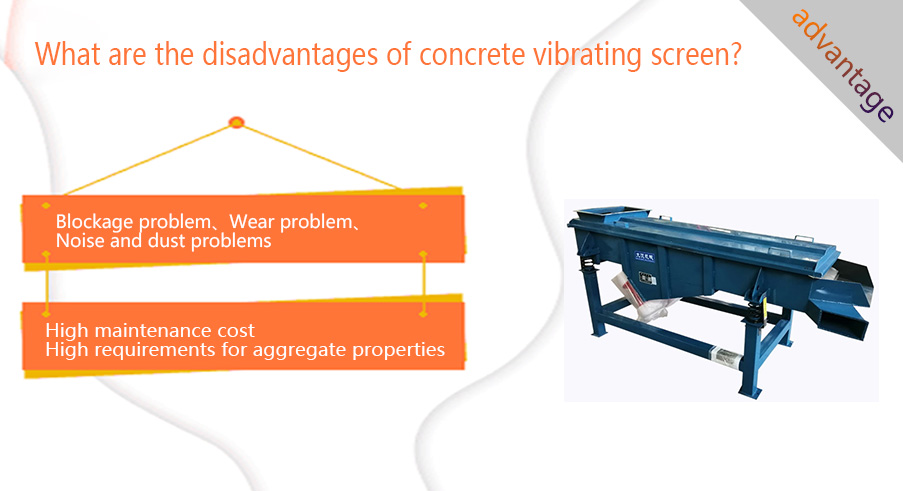

What are the disadvantages of concrete vibrating screen?

1. Blockage problem: For aggregates with high viscosity or materials with high mud content, the screen is easy to be blocked, affecting the screening efficiency. When the screen hole is too small and the material fineness modulus is large, the screen hole is prone to blockage. Uneven or damaged screen surface can also cause material blockage.

2. Wear problem: Under long-term operation, the screen will be worn by the material, causing the screen hole to deform and become larger, affecting the screening accuracy. Vibration motors, bearings and other components will wear out after long-term operation, affecting the stability of the equipment.

3. Noise and dust problems: Concrete vibrating screens will generate certain noise when working, which will affect the working environment. A large amount of dust will be generated during the screening process, which will harm the environment and the health of operators.

4. High maintenance cost: The screen, vibration motor and other components of the concrete vibrating screen are easy to wear and need to be replaced and maintained regularly. Frequent maintenance and replacement of parts will increase the cost of equipment use and may affect production efficiency.

5. High requirements for aggregate properties: Concrete vibrating screens are sensitive to the moisture, viscosity and shape of aggregates. Aggregates that are too wet or sticky may result in poor screening results. In some cases, aggregates need to be pre-treated (such as drying or cleaning), which increases the process and cost.

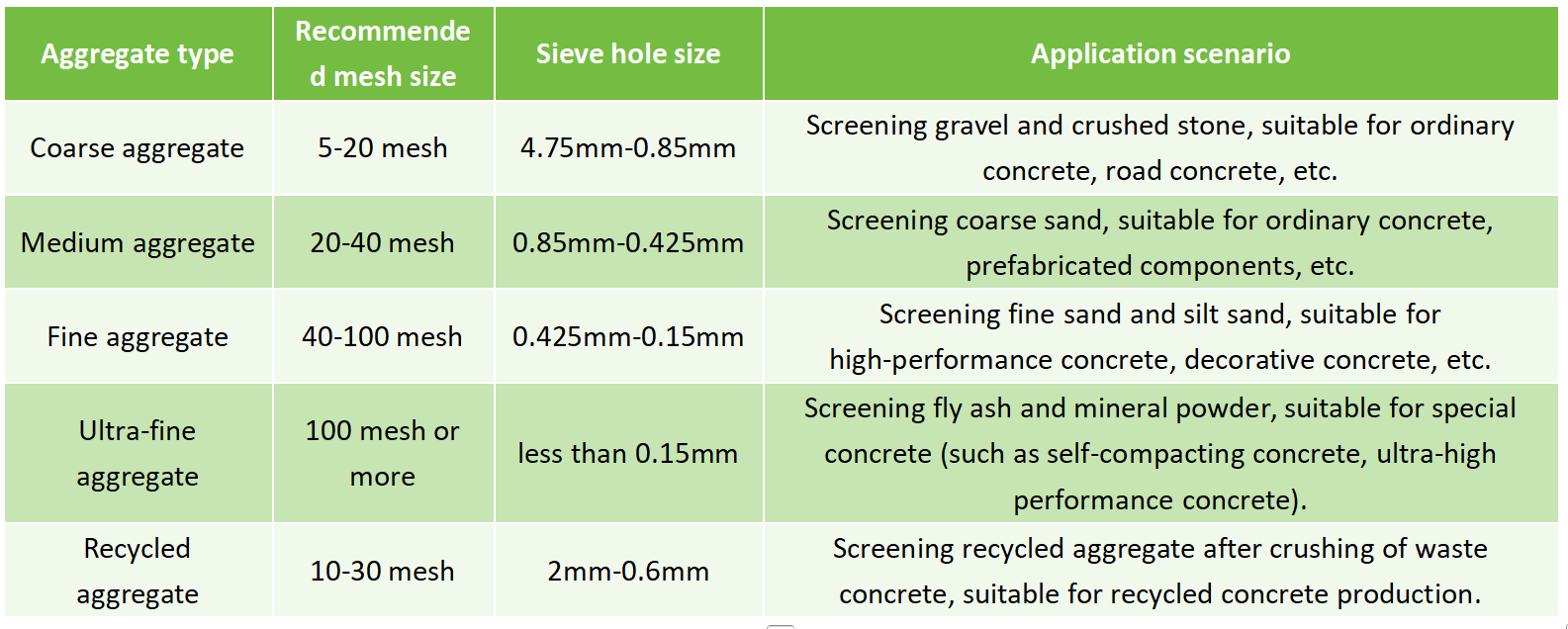

Recommended mesh size of concrete vibrating screen

Application of concrete vibrating screen

1. Aggregate screening: coarse aggregates (such as crushed stone and pebbles) are screened according to different particle sizes to meet the requirements of different concrete formulas. Fine aggregates (such as sand) are screened according to different fineness moduli to ensure the density of concrete.

2. Recycling: At the concrete mixing station or construction site, the vibrating screen is used to screen the residue after concrete mixing to recycle the usable aggregates and reduce waste.

3. Quality control: Through screening, the particle size distribution of aggregates in concrete can be controlled to ensure the quality of concrete. Impurities in concrete, such as soil and debris, can be screened out to improve the durability of concrete.

4. Special concrete production: When producing special concrete such as high-performance concrete and self-compacting concrete, the particle size of aggregates is required to be higher, and the vibrating screen can provide precise screening.

Concrete vibrating screen plays an important role in concrete production. It is mainly used to separate aggregates of different particle sizes in concrete to ensure the quality and uniformity of concrete. Screening can improve the quality of concrete and ensure the quality of the project. When choosing a concrete vibrating screen, you should choose the appropriate equipment according to your specific production needs.

-

High-precision screening of materials is achieved through a unique screening method

-

Filter flour and remove unwanted particles to ensure product quality

-

Steel fiber vibrating screen

Steel fiber vibrating screen is a kind of vibrating screening equipment specially used for...

-

Soy product vibrating screen

Soy product vibrating screen is a screening device specially designed for the production of...

-

Moxa linear vibrating screen

Moxa linear vibrating screen is a screening device specially designed for moxa processing. It is...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.