Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial production. It is mainly used to screen various powdery or granular materials to separate particles of different sizes. Through screening, the purity of the product can be improved, the product quality can be improved, and qualified raw materials can be provided for subsequent production processes.When selecting a powder vibrating screen, the appropriate equipment should be selected according to factors such as the characteristics of the material and the screening requirements.

Powder vibrating screen video

How does the powder vibrating screen work

The working principle of powder vibrating screen is to use the vibration motor as the excitation source, and install eccentric weights at the upper and lower ends of the motor to convert the rotational motion of the motor into horizontal, vertical and inclined three-dimensional motion. Powder moves on the screen surface under the action of vibration force, and larger particles of powder are blocked above the screen holes, while smaller particles fall through the screen holes into the collector below, thereby achieving separation and screening.

Advantages of Powder Vibrating Screen

1. Good self-cleaning function: It has a unique self-cleaning mechanism, which can ensure that the mesh of the screen is always unobstructed, effectively avoid blockage problems, and maintain efficient screening.

2. Optimization of material characteristics: The characteristics of the screened materials can be cleverly adjusted to meet the screening needs of various complex materials.

3. Efficient screening: It is suitable for screening materials of 40-635 mesh, especially when processing particles below 100 mesh, and the performance is more outstanding, which can effectively increase the output by 70% or even up to 10 times.

4. Ultra-high precision screening: It has excellent solution capabilities for screening problems such as strong adsorption, easy agglomeration, high static electricity, high density and light specific gravity, and the screening accuracy is extremely high.

Factors affecting the selection of mesh size of powder vibration screen

Fluidity: Powders with good fluidity can quickly disperse and pass through the screen. You can choose a higher mesh screen for fine screening to obtain a product with a narrower particle size distribution. Powders with poor fluidity tend to accumulate and agglomerate on the screen surface. To avoid clogging the screen, you should choose a screen with a slightly lower mesh to ensure a smooth screening process.

Viscosity: Powders with high viscosity tend to adhere to the screen, affecting the screening efficiency and effect. It is usually necessary to choose a screen with a lower mesh and a larger aperture to facilitate the passage of materials and reduce adhesion. Powders with low viscosity can be screened by choosing a screen with a suitable mesh according to their particle size and other characteristics.

Recommended mesh number of Powder vibrating screen

Generally speaking, the mesh number of powder has a wide range, ranging from dozens of meshes to hundreds of meshes. The specific mesh number selection needs to be determined according to the actual application requirements.

Coarse-grained powder: The mesh number is generally between 40-100 meshes, mainly used in metallurgy, ceramics and other industries.

Medium-grained powder: The mesh number is generally between 100-200 meshes, widely used in electronics, chemical and other industries.

Fine-grained powder: The mesh number is generally above 200 meshes, used in electronics, medicine and other industries with higher requirements.

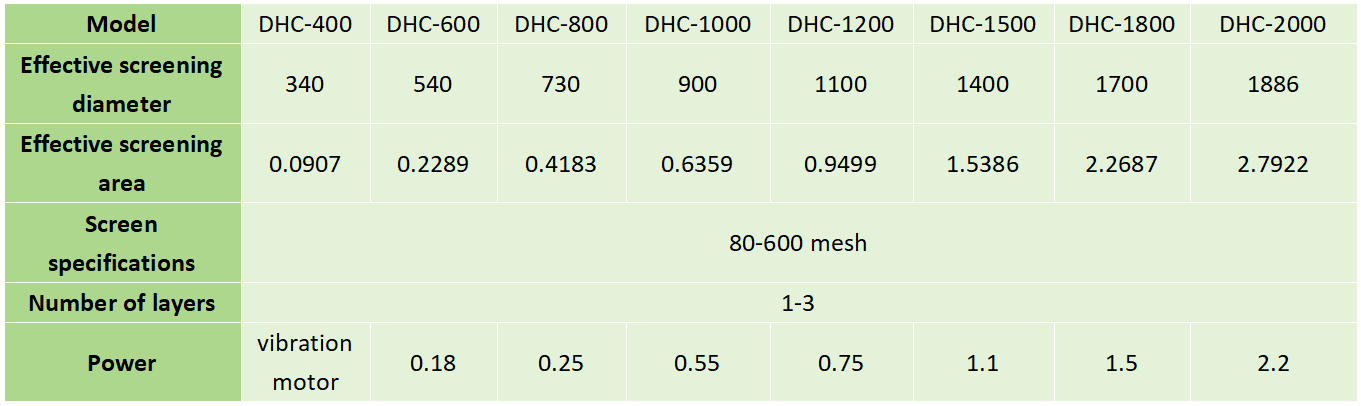

Technical parameters of Powder vibrating screen

Application of Powder Vibrating Screen

1. Chemical industry: used for screening and grading of various chemical raw materials, intermediates, catalysts and other powder materials, such as plastic particles, rubber powder, pigments, fertilizers, etc.

2. Food industry: Screening of food raw materials such as flour, starch, powdered sugar, milk powder, condiments, etc., to remove impurities and unqualified particles, and ensure the quality and taste of food.

3. Pharmaceutical industry: In the process of drug production, raw materials, pharmaceutical excipients, Chinese medicine powder, etc. are screened to ensure that the particle size of the drugs meets the quality standards and improve the stability and efficacy of the drugs.

4. Mining industry: Screening and grading of ore to provide materials with suitable particle size for subsequent crushing, grinding, beneficiation and other processes, and improve beneficiation efficiency and resource recovery rate.

5. Building materials industry: used for screening of powder materials such as cement, gypsum powder, quartz sand, ceramic raw materials, etc., to control the particle size of the product and ensure the quality and performance of building materials products.

Powder Vibrating Screen is an efficient and practical screening equipment, which is widely used in many industrial fields. When selecting and using it, it should be reasonably selected according to the specific application scenario and needs to ensure the screening effect and production efficiency.

-

Screening and filtering of particles, powders, liquids and other materials

-

Filter wheat flour and remove unwanted particles to ensure product quality

-

Titanium powder vibrating screen

Titanium powder vibrating screen is used to screen titanium powder, ensure quality and improve perfor ...

-

Milk powder vibrating screen

Milk powder vibrating screen is an important equipment in milk powder processing, which classifies mi ...

-

Pharmaceutical powder vibrating screen

The pharmaceutical powder vibrating screen is used for screening pharmaceutical powders to ensure dru ...

-

Putty powder vibrating screen

Putty powder vibrating screen Putty powder is screened and impurity-removed to remove impuritie ...

-

River sand linear vibrating screen

River sand linear vibrating screen is a commonly used screening equipment, which is used to...

-

Chemical liquid vibrating screen

Chemical liquid vibrating screen is a device used for solid-liquid separation or liquid filtration...

-

Titanium powder vibrating screen

Titanium powder vibrating screen is a device specially used for screening titanium powder. It is...

-

Plastic particle vibrating screen

Plastic particle vibrating screen is a device specially used for screening plastic particles...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.