Food Grade Vibro Sifter

Callback

| Layers: 1-5 | Mesh: 2-500 mesh (0.025mm) |

| Output: 100-3300kg/h | Diameter: 400mm-1800mm |

Application: flour, spices, rice, corn, soy milk, pineapple juice, beans, etc.

Material: 304/316 stainless steel

Model: DH-400/600/800/1000/1200/1500/1800 (customizable)

Price: $800.00-$4,500.00/Set

In food processing, there is a lot of potential contamination that can get into your product: dirt, pebbles, insect eggs, hair, wood chips, etc., these issues will make people say "no" to your product. How to solve it, then quickly say "hi" to the food grade vibro sifter.

Introduction of food grade vibro sifter:

Food grade vibro sifter is mainly used to sieve various food materials, fine powder, micro powder, dry and wet materials, etc. The vibro sifter is made of the highest quality stainless steel, namely SS 304 and 316L, with mirror polishing, the inner and outer surface finish is 0.1-0.2 RA, all welded joints are seamless, ensuring no material deposits and zero possibility of material contamination, meeting the highest standards of food industry regulations.

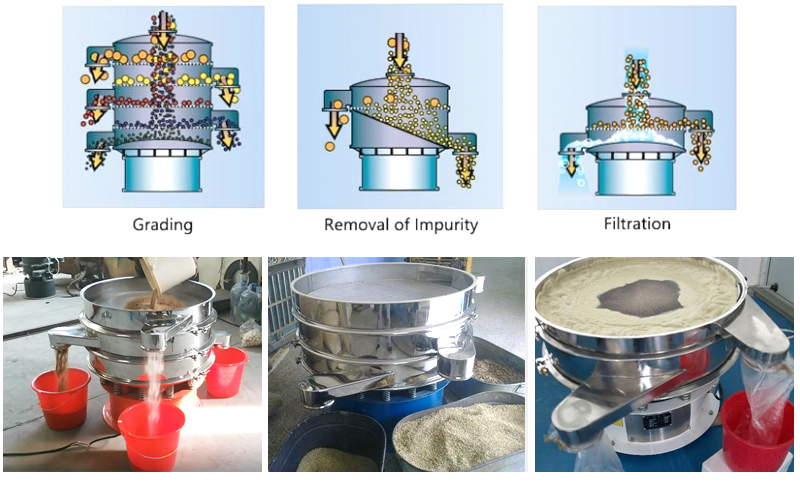

The role of food grade vibro sifter:

1. Screening impurities

Used to remove broken or undersized products such as lumps and other contaminants for final quality checks.

2. Particle size classification

Similar to inspection sieves, but provides more precise separation of sieved products. The purpose of the grading screen is to accurately separate particles of different sizes from the product, so that the final material is classified into different sizes. This is usually achieved by passing the product through a grid of up to 5 different aperture sizes.

3. Solid-liquid separation

It can quickly remove insoluble solid substances in various slurries, and can contact slag discharge. Most are single-layered, but multiple layers can also be used.

4. Batch filtering

Food grade vibro sifter can be combined with the upper silo and subsequent food processing steps. Because the hygiene standards required by the food industry are very high. Therefore, stainless steel food grade vibro sifter is recommended.

Improves product quality and safety by breaking down lumps and filtering out oversized particles, contaminants and debris, ideal for small processes, batch production or short production runs.

The advantages of food grade vibro sifter:

1. Hygienic operation

Food grade vibro sifter is made of 304 stainless steel and polished inside and out. All rubber parts are made of special silicone material for the food industry, which is non-toxic, odorless, clean and hygienic.

2. Closed system

The fully sealed structure can prevent the material from spilling during the screening process, which wastes the material and also causes pollution to the working environment.

3. Mirror polishing

With a 0.1-0.2 RA internal and external surface finish, the mirror finish makes cleaning the machine very easy and helps audit material deposits.

4. Improve product quality

It can eliminate potential contaminants in food raw materials, sieve as fine as 500 mesh or 0.028mm, and filter up to 5 microns.

Technical parameters of food grade vibro sifter

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

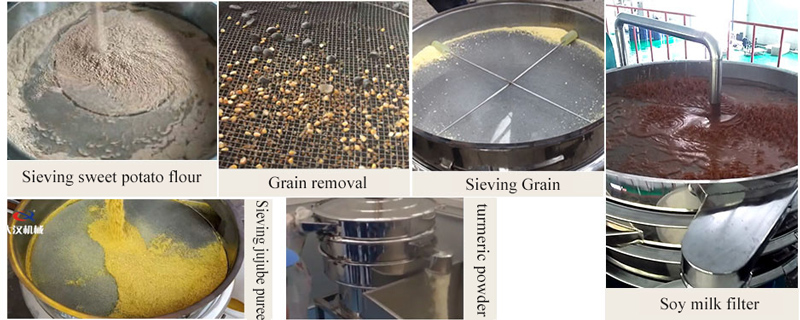

Application of food grade vibro sifter:

Food grade vibro sifter is mainly used for sieving and filtering fine powder, micro powder and dry and wet materials in the food industry, such as: flour, rice, spices, tea, wheat, sesame, chili powder, chocolate powder, cocoa powder, coconut powder, Coffee powder, seasoning, salt, yeast, milk powder, batter, syrup, syrup decolorization, soy milk, fruit juice, etc.

Our solution:

Running a new food processing plant, how do I choose the right flour screening machine?

| Application of food grade vibro sifter in food industry | |||||

| Material | Proportion | Mesh | Model | Processing method | Capacity (kg/hr IT/hr) |

| Wheat flour | 1 | 250 | DH-1200-1S | Wet | 3200 IT |

| Flour | 0.6 | 24 | DH-1000-1S | Dry | 1500㎏ |

| Yeast liquid | 0.5 | 32 | DH-1000-1S | Wet | 8000 IT |

| Rice flour | 0.5 0.8 | 100 | DH-1000-1S | Dry | 300 ㎏ |

| Soy sauce | 1 | 100 | DH-1200-1S | Wet | 6500 IT |

| Salt | 1.2 | 30/80 | DH-1500-1S | Dry | 5000㎏ |

| Tofu | 1 | 120 | DH-1000-1S | Wet | 2500 IT |

| Sweetener | 0.7 | 40/80 | DH-800-2S | Dry | 320㎏ |

| Granulated sugar | 1.2 | 12 | DH-1500-1S | Dry | 8000㎏ |

| Pineapple juice | 1 | 100 | DH-1000-1S | Wet | 3000㎏ |

| Skim milk powder | 0.57-0.7 | 24 | DH-1200-1S | Dry | 3000㎏ |

| Whole milk powder | 0.57-0.8 | 12 | DH-1000-1S | Dry | 1600㎏ |

| Orange juice | 1 | 5.3㎜ | DH-1000-2S | Wet | 2000㎏ |

| Rice bran | 0.5 | 16 | DH-800-1S | Dry | 500㎏ |

| Instant soup powder | 0.6-0.8 | 6.8 | DH-800-2S | Dry | 360㎏ |

| Powdered sugar | 0.5-0.8 | 100 | DH-800-1S | Dry | 200㎏ |

| Corn starch | 0.6 | 40 | DH-1000-1S | Dry | 1600㎏ |

| Chlorophyll | 0.25-0.4 | 48/200 | DH-800-2S | Dry | 100㎏ |

| Animal and vegetable glue | 0.5 | 40 | DH-800-1S | Dry | 500㎏ |

Related cases:

-

Screen pure milk powder so that it does not have any lumps or unwanted particles, dust problems in the factory

-

Sieve before packaging to remove any unwanted impurities and oversized materials

-

The hourly output is 100-3300 kg, and the selectivity is 95%.

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.