How to remove impurities from potato starch vibrating screen

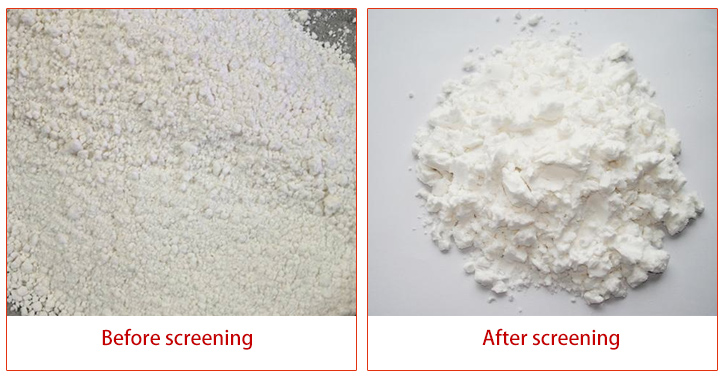

What kind of vibrating screen is used for potato starch sieving and impurity removal. Potatoes, also known as potatoes, are a kind of grains that have certain economic benefits and nutritional value. Potatoes can be made into many delicacies and are a relatively important food crop. It has become the fourth largest food crop in the world. There are many foods that use potatoes as raw materials, not only for stir-frying, but also for making flour. Among them, the fries that many people like to eat are made from potatoes. Its nutrition is also very rich, and it can also have a great feeling of fullness. Potatoes can be made into starch. They can be used as thickeners after they are cooked, dried, and finely ground. Potato starch has the characteristics of large particle size, high viscosity, low gelatinization temperature, strong water absorption, and high transparency of the paste. In the production process of potato starch, vibro sifter is needed to filter out the fiber, cells, powder residue and impurities in potato starch.

Potato starch vibrating screen can usually be processed with a rotary vibrating screen. After the potatoes are ground, the potato starch can be poured into the rotary vibrating screen for sieving treatment, because the particle size of potato starch is generally 35~105μm , The mesh number is about 100-400 meshes, which can be processed with a rotary vibrating screen. Potato starch is relatively viscous. A bouncing ball is installed on the punching plate of the rotary vibrating screen. The force of the bouncing ball hitting the screen can be used to promote the material to go down the screen and reduce the problem of cleaning the screen.

Potato starch vibrating screen uses a vertical motor as the excitation source. The upper and lower ends of the motor are equipped with eccentric weights to convert the rotation of the motor into a horizontal, vertical, and inclined three-dimensional motion, and then transfer this motion to the screen surface. , So that the material expands and involute on the screen surface, so this series of vibrating screens are called rotary vibrating screens. Rotary vibrating screen has the advantages of long material running trajectory and high utilization rate of the screen surface. Adjusting the phase angle of the weights at the upper and lower ends can change the trajectory of the material on the screen surface.

The above is the relevant introduction about what vibrating screen is used for potato starch screening and impurity removal. If you want to know more about the quotation of rotary vibrating screen, linear screen and other products, please call the vibrating screen manufacturer for consultation.

-

Potato Starch Vibrating Screen

The discharging port can be adjusted 360 degrees arbitrarily, which is convenient to connect with the scene. ...

-

Screening, filtering and impurity removal of fine powder ...

-

5 tips for selecting the most suitable vibro sifter

The vibro sifter can be suitable for screening and filtering of any particles ...

-

Common faults and solutions for vibro sifter

As the most common fine screening equipment, the vibro sifter has high screening precision ...

-

Starch Vibro Sifter

Starch Vibro Sifter is a common starch processing equipment, mainly used for grading and sieving starch. It has many advantages ...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.