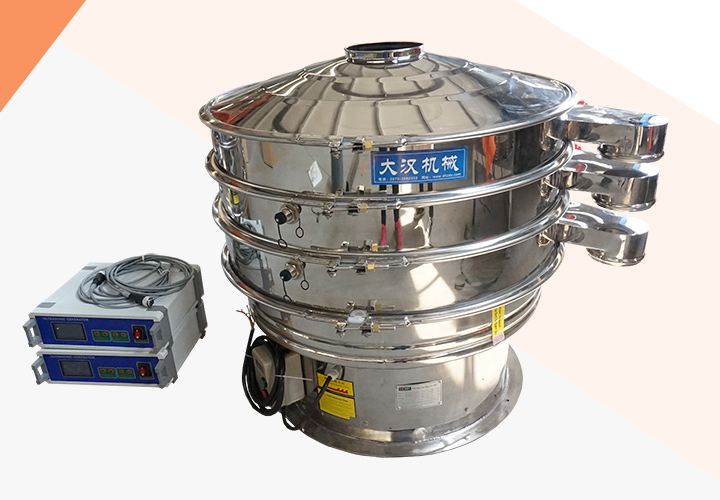

Potato Starch Vibrating Screen

![[field:title/]](/uploads/211120/1-211120154G2G1.jpg)

Callback

| Model | DH400-DH2000 |

| Capacity | 100-3300kg/h |

Good airtightness, no dust flying, ensuring the cleanliness of the operating environment.

The movement of the net cleaning device such as the bouncing ball

which is beneficial to clean up the residual materials on the screen.

Introduction of potato starch vibrating screen

Potato starch vibrating screen is a screening equipment specially designed for potato starch, corn starch, wheat starch, cellulose, soybean, peanut protein, flour, tapioca starch and other starch materials and derivatives of starch materials. It is used to remove impurities and agglomeration in potato starch, and also has the function of loose material.

Potato starch vibrating screen commonly used 60 mesh, 80 mesh, 100 mesh stainless steel screen with a diameter of 1000mm or 1500mm, single layer. Screen starch before packaging. The production capacity is about 2-3.5 tons/hour.

What is the applicable material range of the potato starch vibrating screen?

Core applicable materials

Starch

Root starch (potato starch, cassava starch, sweet potato starch, taro starch) has coarse particles (15-100μm) and needs to be graded to remove fibers and impurities.

Cereal starch (corn starch, wheat starch, rice starch) has finer particle size (5-50μm) and requires a high mesh screen (200 mesh or more).

Modified starch (hydroxypropyl starch, acetate starch, etc., need anti-sticking screening)

Food powder

Edible powder (impurity removal or classification of dry powders such as flour, rice flour, bean flour, lotus root powder, etc.)

Seasoning (screening of powdered sugar, monosodium glutamate, yeast powder, moisture-proof design is required)

Industrial powder

Soluble powder (cellulose powder, plant protein powder) (easy to absorb moisture, need closed screening)

Inorganic powder (talcum powder, diatomaceous earth) (particle size close to starch, can share equipment)

Unsuitable/cautious materials

| Material type | reason | alternative solution |

| High viscosity slurry (such as sauce) | easy to block the screen, poor fluidity | centrifugal screen or filter press |

| Highly corrosive chemicals | damaged stainless steel screen | plastic material vibrating screen |

| High temperature materials (>80℃) | affect the life of seals | screening after cooling or high temperature resistant equipment |

| Slag with fiber content >30% | need to be pre-treated by centrifugation or coarse screening | screw extrusion screen + vibrating screen combination |

Benefits of potato starch vibrating screen

1. It adopts 304 stainless steel, and the cleaning device and sealing device adopt silica gel ball and silica gel ring respectively, which meets the hygiene standards of the food industry.

2. The movement of the net cleaning device such as the bouncing ball, the screen has a high penetration rate, which is beneficial to clean up the residual materials on the screen.

3. Good airtightness, no dust flying, ensuring the cleanliness of the operating environment.

4. The discharging port can be adjusted 360 degrees arbitrarily, which is convenient to connect with the scene.

Working principle of potato starch vibrating screen

Potato starch vibrating screen uses the YZUL vertical vibration motor as the excitation source, and uses the eccentric weights at the upper and lower ends of the vibration motor to convert the rotary motion into a horizontal, vertical, and inclined three-dimensional motion, which is transmitted to the screen surface of the rotary vibrating screen; The material enters the equipment through the inlet. According to different material screening requirements, the material passes through the sieve of the sieve for layering. In this process, the bouncing ball, a cleaning device located under the sieve, continuously hits the sieve, causing the sieve to be layered. The material can be screened through the mesh smoothly and effectively solves the problem of material blockage. The over-screen material and under-screen material are discharged from different outlets , so as to achieve the purpose of screening and removing impurities or filtering and grading.

Recommended mesh number of potato starch vibrating screen

| Screening purpose | Recommended mesh number (mesh) | Function description |

| Primary screening (impurity removal) | 10-40 mesh | Remove large particle impurities, fibers, and uncrushed lumps |

| Fine screening (finished product grading) | 80-120 mesh | Increase starch fineness, remove coarse particles, and ensure uniformity |

| Ultrafine screening (high purity requirements) | 150-200 mesh | Improve starch quality to meet the needs of high-end food, pharmaceuticals, etc. |

| Starch slurry filtration | 200-300 mesh | Filter fine impurities in starch slurry to improve extraction rate |

Technical parameters of potato starch vibrating screen

| Model |

Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers |

Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

What is the purpose of a potato starch vibrating screen?

Potato starch vibrating screen can be used for screening, impurity removal, loose materials, etc. It is suitable for 24 hours continuous production and large processing capacity. In addition, it is also suitable for wheat starch, corn starch, tapioca starch, sweet potato starch, potato starch, starch derivatives, cellulose, soy protein powder, peanut protein powder, flour, PVC powder, steel grit and other powders.

How to fix a potato starch vibrating screen?

Daily inspection

Check the screen (whether it is damaged or loose, and replace it in time); check the motor (whether it runs smoothly, whether there is any abnormal noise or overheating); check the spring (whether it is broken or deformed, affecting the vibration effect); check the screws (after long-term use, the vibration screen bolts may loosen and need to be tightened regularly).

Motor maintenance

Replace the grease every 6 months to avoid bearing wear.

If the motor is abnormally hot or the vibration intensity becomes weak, it may be that the coil is damaged and needs to be replaced or repaired.

Screen replacement: Turn off the power, ensure the safety of the equipment, remove the screws that fix the mesh frame, remove the old screen, install the new screen, tighten and fix it to prevent loosening, check the sealing strip to avoid dust leakage.

-

Screening, filtering and impurity removal of fine powder ...

-

SUltra-fine powder with high fineness, light specific gravity ...

-

Mainly used for powder, granule and liquid materials ...

-

In the case that the mealworms are not harmed, the dry bugs are separated from the impurities, instead of manual sorting.

-

Ensure accurate particle size of metal powder and remove excessive contaminants.

-

Remove solids from liquid slurries and recover valuable materials in the waste stream for reuse.

-

What is the applicable range of Potato Starch Vibrating Screen?

The commonly used material of Potato Starch Vibrating Screen is 304 or 316L stainless steel, which ha ...

-

How to remove impurities from potato starch vibrating screen

What kind of vibrating screen is used for potato starch sieving and impurity removal. Potatoes, also ...

-

5 tips for selecting the most suitable vibro sifter

The vibro sifter can be suitable for screening and filtering of any particles ...

-

Common faults and solutions for vibro sifter

As the most common fine screening equipment, the vibro sifter has high screening precision ...

-

Starch Vibro Sifter

Starch Vibro Sifter is a common starch processing equipment, mainly used for grading and sieving starch. It has many advantages ...

-

What is the applicable range of Potato Starch Vibrating Screen?

The commonly used material of Potato Starch Vibrating Screen is 304 or 316L stainless steel, which has the characteristics of high...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.