Porcelain slurry vibrating screen

Porcelain slurry vibrating screen is a special equipment used to screen porcelain slurry. Porcelain slurry is an important intermediate material in the ceramic production process, including ceramic raw material particles and liquid media. The vibrating screen sieves the porcelain slurry through vibration to remove impurities, control particle size, etc., and ensure that the quality of the porcelain slurry meets the requirements of subsequent ceramics. Production process requirements.

Working principle of Porcelain slurry vibrating screen

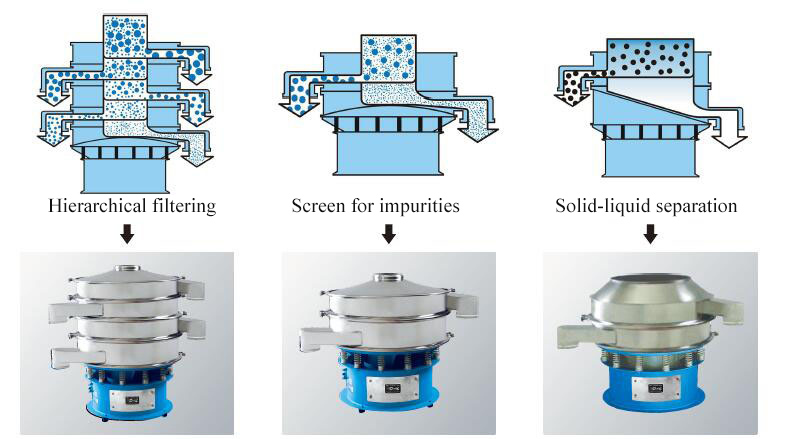

The porcelain slurry vibrating screen passes through the high-frequency vibrating screen mesh to cause the materials to jump on the screen surface and pass through the screen holes, thereby achieving solid-liquid separation. The hole size on the screen determines the screening particle size. Screens with different mesh sizes can screen particles of different sizes.

Advantages of Porcelain slurry vibrating screen

1. Adjust the liquid flow distribution: Check and adjust the liquid flow distribution of the porcelain slurry on the screen frame to ensure that the slurry can flow through the screen evenly. For example, for a vibrating screen with a hook-edge screen structure, if the screen surface on both sides is lower than the middle, the mud will easily flow to both sides and escape. You can adjust the front spring seat to appropriately raise the angle of the front of the screen box, or adjust the extension. The position of the flip plate of the tank controls the liquid flow distribution and reduces the phenomenon of pulp running.

2. Multi-layer screening technology: Using a multi-layer screening structure, screens with different mesh sizes are set up in the same vibrating screen to screen the porcelain slurry multiple times. For example, the ceramic glaze vibrating screen can be set up with 1-5 screening layers using metal woven screens with different mesh numbers. Materials with different mesh numbers pass through the screens with corresponding mesh numbers on each layer and are discharged from the discharge port of each layer. , thereby achieving more precise screening and impurity removal or filtering and grading.

3. Adjust the vibration trajectory: By adjusting the phase angle of the eccentric weights at the upper and lower ends of the vibration motor and the counterweights, the movement trajectory and excitation force of the material on the screen surface can be changed to achieve the best results for materials with different specific gravity and different mesh numbers. Excellent screening effect, meeting the requirements of high-precision screening.

Application of porcelain slurry vibrating screen

1. Preparation of ceramic raw materials: During the processing of ceramic raw materials, it is used to preliminary screen the mixed porcelain slurry to remove large impurities in the raw materials (such as sand and gravel, incompletely ground massive raw materials, etc.) to ensure that the ceramic slurry is The purity and particle size of the slurry meet the requirements of subsequent ball milling, spray drying and other processes.

2. Ceramic glaze processing: In the production of ceramic glaze, the porcelain slurry vibrating screen can finely screen the glaze slurry to ensure that the solid particles in the glaze are uniform in size. This is very critical to obtain a high-quality ceramic glaze. For example, when firing high-end ceramic vases, uniform glaze particles can make the glaze smooth and even in color.

3. Production of special ceramics: In the manufacturing process of special ceramics, the requirements for particle size control of porcelain slurries are more stringent. The porcelain slurry vibrating screen can accurately screen out the porcelain slurry that meets the requirements of special ceramic production formulas to ensure the performance and quality of special ceramic products. For example, when producing electronic ceramic capacitors, vibrating screens screen out porcelain slurries with precise particle sizes, which help improve the electrical properties of the capacitors.

As an important piece of equipment in the ceramic industry, the porcelain slurry vibrating screen plays an important role in improving product quality and production efficiency. By understanding the working principle, advantages, and applications of the porcelain slurry vibrating screen, you can better select and use the equipment, increase production efficiency, and improve product quality.

-

Screening and filtering of particles, powders, liquids and other materials

-

Filter wheat flour and remove unwanted particles to ensure product quality

-

Diamond Vibrating Screen

Diamond vibrating screen is a device used for screening and grading diamond particles. Through vibration force and screen structure ...

-

Putty powder vibrating screen

Putty powder vibrating screen Putty powder is screened and impurity-removed to remove impurities and fine particles to ensure the quality of p...

-

Sugarcane Juice Bioethanol Vibro Sifter

Sugarcane Juice Bioethanol Vibro Sifter is a device for filtering sugarcane juice, mainly used for sugarcane juice filtration in bioethanol industry. ...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.