River Sand Vibro Sifter

What is ariver sand vibro sifter?

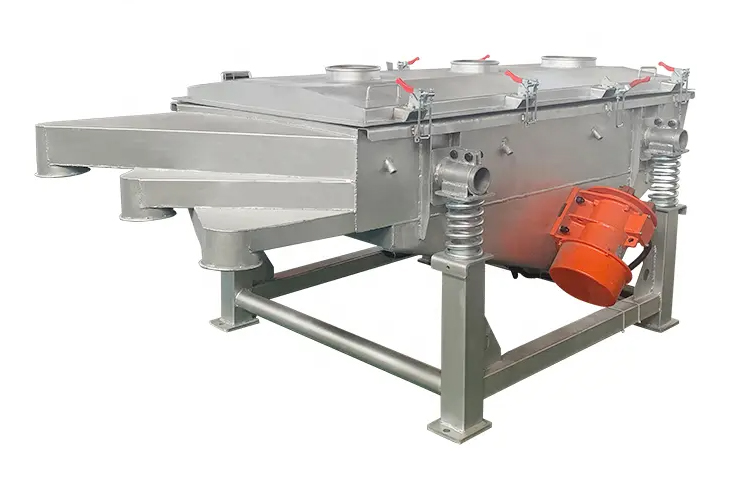

River sand vibro sifteris also called vibrating sand screening machine. River sand vibro sifter is used to separate broken sand or powder, impurities, etc., and then divide the sand into coarse, medium, and fine-grained grades for batching.

In the process of designing sand and gravel production lines, the output of the industry is generally relatively large, and an ordinary single vibro sifter cannot meet its high output requirements, which can only be achieved with multiple sets. 4-6 screening equipment, even a small sand and gravel production line requires at least two vibro sifter equipment.

What is the principle of river sand vibro sifter?

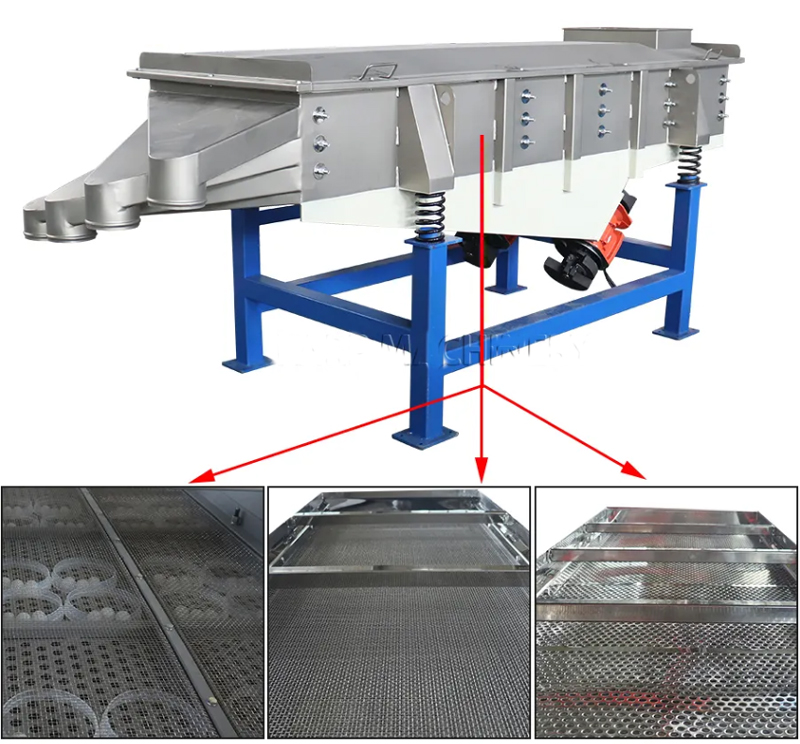

River sand vibro sifter is made of high-quality carbon steel, a distributor is installed at the feed inlet to increase the width of the machine-made sand on the net, and buffer and protect the screen surface; the dual-channel design inside the screen box allows the machine-made sand to be screened and transported on both sides ;5mm woven mesh, detachable steel frame; driven by double motors, strong screening ability.

Screening process: the sand and gravel put into the screen are scattered on the screen and jump forward under the exciting force generated by the dual motors of the same frequency, and the powder and particles smaller than the mesh size in the material fall through the screen. The sundries larger than the mesh size are discharged from the screen surface through the slag outlet, thus completing the screening work.

Advantages ofriver sand vibro sifter

1.Sieve sand

It is suitable for the classification of medium and fine range sand and natural wet sand, such as quartz sand, mullite sand, river sand, manganese sand, foundry sand, machine-made sand, etc.

2.Multi-layer grading

6 decks can be installed to separate different specifications of sand during the screening process, 7 different specifications can be separated, and the sand can be divided into coarse, medium and fine granularity levels.

3.High screening efficiency

Using multiple layers, large inclination angle, and large sieve holes , the screening efficiency is as high as 96%.

4.Large output

Driven by dual motors to ensure proper vibration, it is 3-6 times the output of ordinary screen machines, and the output can reach more than 80 tons/hour.

5.Feed evenly

A distributor can be added to the feeding section to ensure that the sieves are evenly distributed on the screen surface, and at the same time, it can buffer and protect the screen surface.

6.Flexible configuration

The upper cover of the equipment is designed with a dust removal device. It can be easily connected with on-site dust removal equipment. In large production lines, multiple screening equipment can be configured.

What is the application ofriver sand vibro sifter?

River sand vibro sifters aresuitable for variousconstruction projects, water conservancy projects and other fields, such as rivers, lakes, beaches, sponge cities, highways, and other occasions. Sand quality to ensure engineering quality and engineering safety.

Typical applications: It used for separation of sand and gravel in sand and gravel yard, used for grading of large and small stones in stone quarry, and separation of soil and stone powder.

How to help the sand industry for vibro sifter?

1.Screening quartz sand:

It is used to screen and classify quartz sand and other materials. The specifications are: 0.5-1mm, 1-2mm, 2-4mm, 4-8mm, 8-16mm, 16-32mm, 10-20 mesh, 20-40 mesh, 40 mesh -80 mesh and 100-250 mesh can meet various application requirements and ensure that the particle size of quartz sand meets the requirements of use.

2.Screening corundum:

Carborundum is used as abrasive, screening specifications: 0-1mm, 1-3mm, 3-5mm, 5-8mm, 8-10mm, 36 mesh, 46 mesh, 60 mesh, 80 mesh, 100 mesh, 200 mesh, 325 mesh and various A variety of fine powder can be adjusted and produced according to customer requirements.

3.Sieving machine-made sand:

River sand vibro sifter can have 1~8 layers of detachable screen layers according to the production needs of customers, and can screen out 7-9 kinds of machine-made sand with different particle sizes at most. At the same time, the maximum output can reach 40 tons per hour.

2 Layers Single Phase Dry River Sand Vibration Sieve Screening Machine

Inline Vibratory Stone &. Sand Screening Machine

Sieve analysis of river sand

-

Introduction of Tantalum Powder Vibro Sifter Tantalum powder vibro sifter is a device for separation and screening.

-

Introduction of Niobium Powder Vibro Sifter Niobiumpowder vibro sifter is an efficient screening equipment that

-

Introduction of Beryllium Powder Vibro Sifter Berylliumpowder vibro sifter is a vibration sieve for sieving

-

What is coke vibro sifter ? Coke vibro sifter is a device that is used by high -frequency vibro sifter materials

-

How to Apply Powder Coating Ultrasonic Sieving Machine

Powder coating ultrasonic sieving machine is a fine powder sieving machine with relatively perfect te ...

-

Tantalum Powder Vibro Sifter

Introduction of Tantalum Powder Vibro Sifter Tantalum powder vibro sifter is a device for separation and screening. ...

-

Beryllium Powder Vibro Sifter

Introduction of Beryllium Powder Vibro Sifter Berylliumpowder vibro sifter is a vibration sieve for sieving ...

-

Niobium Powder Vibro Sifter

Introduction of Niobium Powder Vibro Sifter Niobiumpowder vibro sifter is an efficient screening equipment that ...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.