Steel fiber vibrating screen

Steel fiber vibrating screen is a kind of vibrating screening equipment specially used for screening steel fiber or other metal fiber materials. It uses the exciting force generated by the vibrating motor to make the steel fiber be layered and screened on the screen surface. It is widely used in industries such as concrete reinforcement, refractory materials, and metallurgy, which can help improve production efficiency, ensure product quality, and achieve goals such as resource utilization and environmental protection.

Steel fiber vibrating screen video

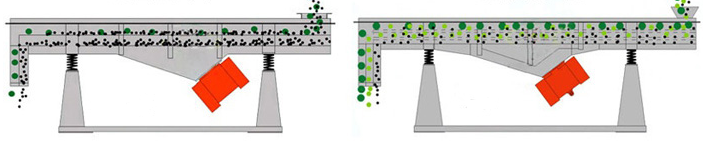

How does steel fiber vibrating screen work

When steel fiber vibrating screen is working, the exciting force generated by the vibrator makes the screen body vibrate at high frequency. The steel fibers are evenly fed to the screen surface through the feeding device. Under the action of vibration, the steel fibers reciprocate on the screen. Due to the different apertures of the screen, the steel fibers smaller than the size of the screen hole will pass through the screen hole and fall to the lower layer, becoming the undersize; while the steel fibers larger than the size of the screen hole will remain on the screen, continue to move on the screen surface, and finally be discharged from the corresponding discharge port. In this way, the screening and grading of steel fibers according to different sizes are achieved.

What is the purpose of a Steel fiber vibrating screen?

1. Steel fiber classification: Steel fibers of different lengths are classified so that steel fibers of different lengths can be used in different concrete products. Ensure that the length of the steel fiber meets the design requirements and improve the crack resistance of the concrete.

2. Remove impurities: In the process of steel fiber production, some impurities such as iron filings and copper filings will inevitably be mixed in. The vibrating screen can effectively remove these impurities and ensure the purity of the steel fiber.

3. Control the content of steel fiber: By adjusting the aperture of the screen, the content of steel fiber in the concrete can be controlled to meet the requirements of different projects.

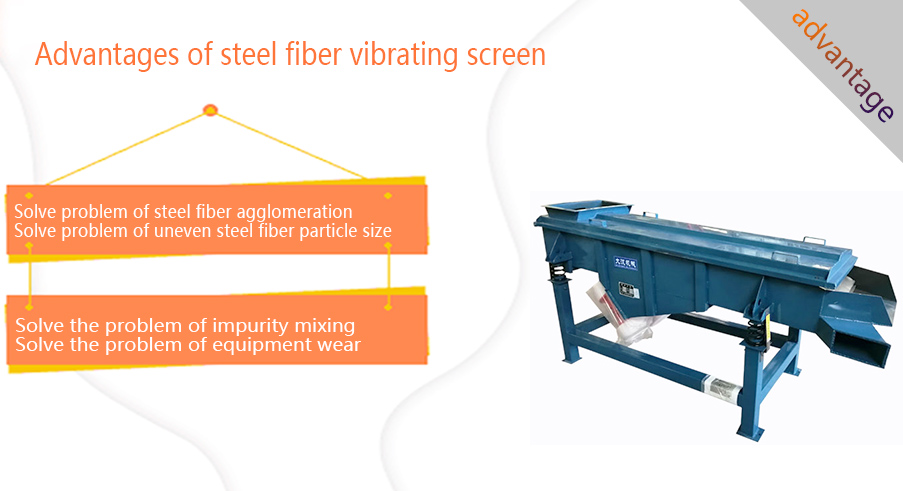

Advantages of steel fiber vibrating screen

1. Solve the problem of steel fiber agglomeration: Steel fibers are prone to agglomeration due to static electricity or entanglement, which affects their uniform distribution in concrete or refractory materials and reduces the reinforcement effect. The steel fiber vibrating screen uses the exciting force to continuously throw and disperse the steel fibers on the screen surface, effectively breaking the fiber agglomeration and making it uniform and loose.

2. Solve the problem of uneven steel fiber particle size: Steel fibers may have inconsistent lengths or diameters during the production process. Equipped with multi-layer screens, it can be accurately graded according to the length or diameter of the steel fibers to ensure that steel fibers of different specifications are separated to meet the needs of different application scenarios.

3. Solve the problem of impurity mixing: Metal chips, dust or other impurities may be mixed into steel fibers, affecting product quality. The steel fiber vibrating screen separates impurities from steel fibers through screening, and the impurities are discharged from the waste port to ensure the purity of the steel fibers.

4. Solve the problem of equipment wear: Steel fibers have high hardness and are easy to cause wear to screening equipment, shortening the life of the equipment. Steel fiber vibrating screen is made of wear-resistant materials, such as high manganese steel mesh or polyurethane mesh, which significantly improves the durability of the equipment and reduces maintenance costs.

Application of Steel Fiber Vibrating Screen

Steel fiber vibrating screen is commonly used for material processing in the fields of ore, coal, building materials, chemical raw materials, etc. It is also widely used in industrial sectors such as ore dressing, metallurgy, coal, chemical industry, building materials, and grain.

Ore classification: Steel fiber vibrating screen is used for grading and screening of ore to improve the grade and output of ore.

Coal dehydration: Steel fiber vibrating screen is used in coal dehydration process to reduce the moisture content of coal and improve combustion efficiency.

How to fix a steel fiber vibrating screen?

Local repair: If the screen is only damaged in a small area, you can use the wire weaving repair method. First clean the edges of the damaged area to remove debris and burrs, then use the wire of the same material as the screen, and repair it according to the weaving method of the screen to ensure that the repair is flat and firm, and does not affect the screening effect.

Overall replacement: When the screen is damaged in a large area or aged severely, the screen needs to be replaced as a whole. First remove the old screen and take care to keep the accessories that fix the screen. Clean the surface of the screen to ensure that there is no debris and rust, then place the new screen flat on the screen, and use the original fixing accessories or a dedicated screen fixing device to fix the screen firmly, ensuring that the screen tension is moderate to avoid looseness or overtightening.

manufacturer of steel fiber vibrating screens

Steel fiber vibrating screen plays a vital role in the production process of steel fiber concrete. By screening the steel fibers, the quality and uniformity of the steel fibers can be guaranteed, thereby improving the performance of the concrete.

-

High-precision screening of materials is achieved through a unique screening method

-

Filter flour and remove unwanted particles to ensure product quality

-

Soy product vibrating screen

Soy product vibrating screen is a screening device specially designed for the production of...

-

Moxa linear vibrating screen

Moxa linear vibrating screen is a screening device specially designed for moxa processing. It is...

-

Carbon material vibrating screen

Carbon material vibrating screen is a device specially used for screening carbon materials. Carbon...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.