Steel shot vibrating screen

Steel shot vibrating screen is a device used for screening steel shot. Steel shot is a metal abrasive mainly used for surface cleaning, strengthening, other treatment processes of workpieces. The steel shot vibrating screen generates vibration through a vibrating motor or other vibrating devices, causing the steel shot to move on the screen, thus screening and grading the steel shot according to its size. This device is widely used in industrial production to improve production efficiency and product quality.

Working principle of Steel shot vibrating screen

The motor drives the exciter to make the screen box produce vibration of certain frequency and amplitude. The on the screen box has different pore sizes. When the steel shot moves on the vibrating screen, the steel shot smaller than the screen holes will pass through the screen fall into the next layer or the discharge port, while the steel shot larger than the screen holes will be retained on the screen surface, thus achieving the grading of steel shot.

Advantages of Steel shot vibrating screen

1. Preventing Blockages: Steel shot is prone to clog on the screen, and specially designed screens are used to ensure that the material flows smoothly the screen and reduce clogging.

2. Reducing Adhesion: During the screening process, steel shot may exhibit adhesion, leading to particle clustering that is difficult to separate. steel shot vibrating screen mitigates this by using appropriate vibration frequency and amplitude, thereby reducing material adhesion and enhancing screening efficiency.

3. Controlling Dust: The process of steel shot can generate dust, which affects the production environment and the health of workers. Vibrating screens can be equipped with enclosed structures or dust suppression devices effectively controlling dust generation and maintaining a clean production environment.

4. Optimizing Screen Mesh Design: Steel shot vibrating screens often select the appropriate screen mesh based on material and screening requirements. Optimizing the screen mesh design can improve screening efficiency and ensure screening accuracy.

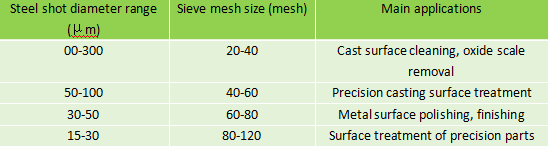

Recommendations for Steel Shot Vibrating Screen Mesh Sizes

Applications of Steel shot vibrating screen

Steel shot vibrating screen has many specific application scenarios in the industrial field, mainly involving production, processing, and screening of steel shot. Here are some specific application scenarios of the steel shot vibrating screen:

1. Steel shot production: Steel shot vibrating screen is used to screen and classify the produced steel shot. By separating steel shot of different particle sizes, it ensures product quality and meets customer needs.

2. industry: Steel shot is widely used in the casting industry for surface treatment and cleaning of workpieces. Steel shot vibrating screen can be used to screen and clean steel shot used in casting, ensuring the quality and finish of the castings.

3. Metal processing: Steel shot is commonly used as a grinding medium in metal to remove surface oxides, clean, and enhance the metal surface. Steel shot vibrating screen can be used to screen and classify the metal shot, ensuring the effect and processing quality.

4. Abrasive production: Steel shot is also commonly used as an abrasive. In the process of abrasive production, Steel shot vibrating screen can be used to screen and classify the abrasive particles to meet the demand for different particle sizes.

5. Granular material screening: Steel shot vibrating screen can be applied to other granular material screening scenarios, such as screening and classifying granular materials like ore, chemical raw materials.

Recommendations for Selecting Steel shot vibrating screen

Steel Shot Size Distribution: Select the appropriate screen mesh size based on the size of the steel shot.

Processing Capacity: Choose the processing capacity according to production requirements.

Screening Precision: Select the appropriate screening precision based on process requirements.

Working: Consider factors such as temperature and humidity of the working environment.

Steel shot vibrating screen plays an important role in the processes of steel shot production, cleaning, and screening, improving product quality to ensure that the can meet production requirements.

-

Screening and filtering of particles, powders, liquids and other materials

-

Filter wheat flour and remove unwanted particles to ensure product quality

-

Milk powder vibrating screen

Milk powder vibrating screen is an important equipment specially used in the processing and production of milk...

-

Cranberry vibrating screen

Cranberry vibrating screen is a screening equipment specially designed for cranberries and other fruits and...

-

Corn starch vibrating screen

Corn starch vibrating screen is a specialized piece of equipment used for screening corn starch. It uses...

-

Popcorn vibrating screen

Popcorn vibrating screen is a screening equipment specially designed for the popcorn processing industry. It...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.