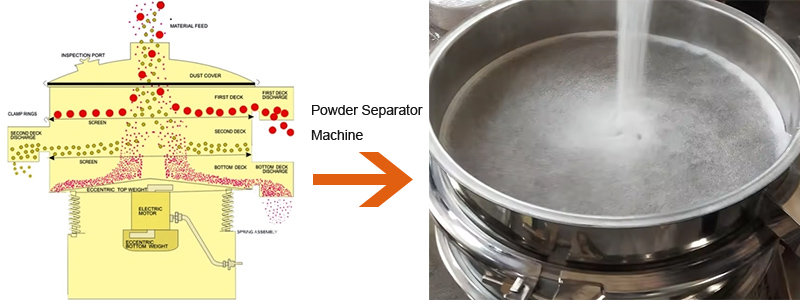

Powder Separator Machine

![[field:title/]](/uploads/211112/1-211112152114b6.jpg)

Callback

| Screening mesh number: | 2-500 mesh |

| Capacity: | 100-5000kg/h |

The powder is sieved on a finer mesh to improve product quality and consistency

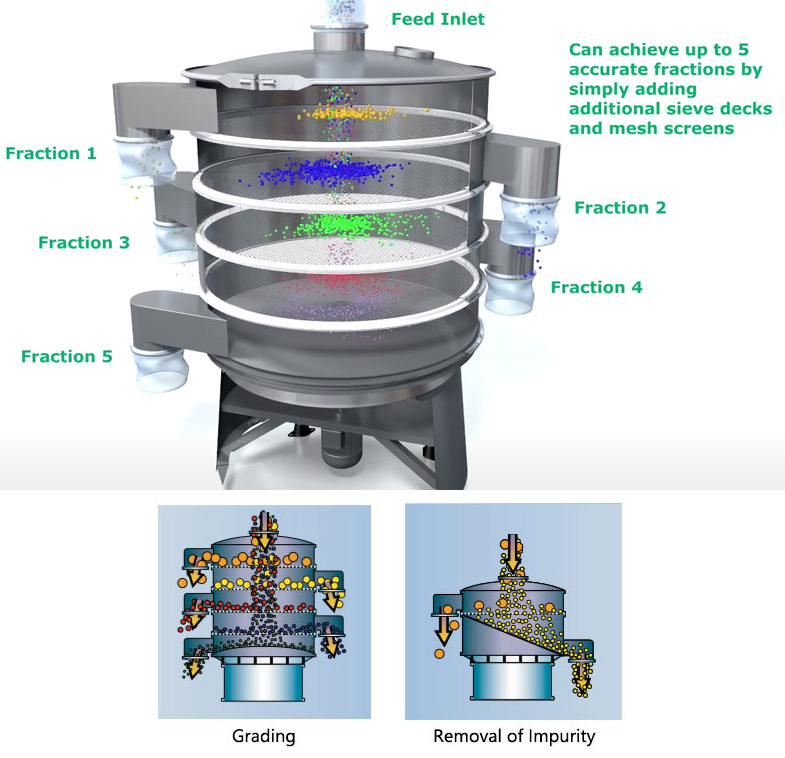

Can be screened and classified by 5 sieve plates to achieve precise separation

Fully enclosed structure prevents dust and smoke from leaking

What is a powder separator machine?

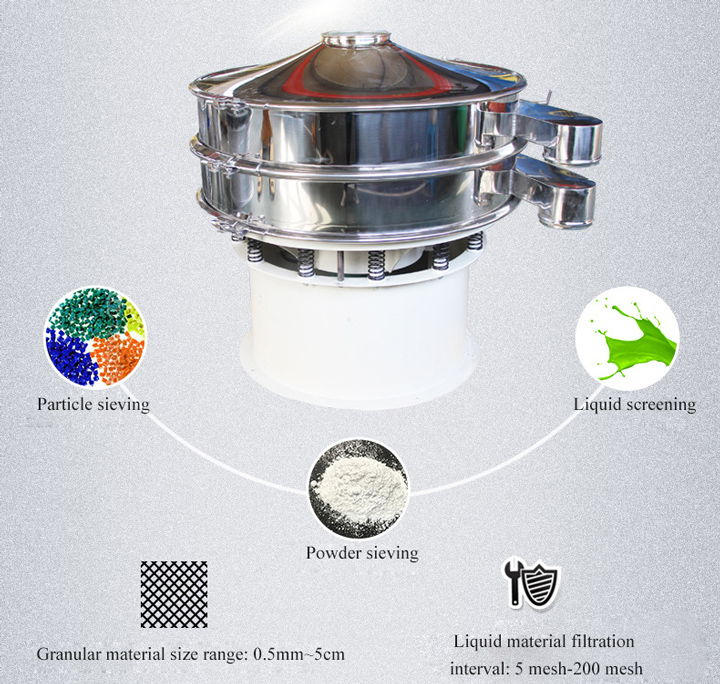

Powder separator machine, also known as a powder classifier or powder concentrator, is a device used in various industries to separate and classify fine particles based on their size, shape, density, and other properties. The primary function of a powder separator machine is to efficiently separate particles of different sizes or characteristics from a powder mixture, allowing for the precise control of particle size distribution and the segregation of materials for further processing.

What is the powder separation machine used for?

1. Remove impurities: Powder separator machine can effectively remove impurities in particles, such as clumps, fibers, metal foreign matter, etc. Through the screening process, impurities can be separated from the product, improving the quality and purity of the product.

2. Classification: Powder separator machine can screen raw materials or products and divide particles into different size ranges according to particle size. Through different screen apertures, fine powder, medium powder and coarse powder can be separated.

The following are common application industries:

1.Powder Coating Industry: Powder separator machines are used in the powder coating industry to separate oversize particles and ensure a consistent particle size distribution for high-quality coating applications.

2.Pharmaceutical Industry: In pharmaceutical manufacturing, powder separators are utilized to separate fine drug particles for precise dosing and formulation of medications.

3.ineral Processing: Powder separators play a critical role in the mineral processing industry by separating valuable minerals from waste materials based on their size and density.

4.Food Processing: In the food industry, powder separator machines are used to classify food powders such as flour, sugar, and spices, ensuring product quality and consistency.

What are the suitable materials for the powder selection machine?

| Material type | Characteristic description | Applicable powder selection machine type | Typical industry application | Precautions |

| Granular materials | Dry solid particles (0.1-10mm) | Rotary vibrating screen, linear vibrating screen, air classifier | Flour, fertilizer, plastic particles | Dustproof design required, anti blocking mesh |

| Particle liquid mixture material | Suspension or slurry containing solid particles | Filter screen, centrifugal screening machine, wet rotary vibrating screen | Juice, ceramic slurry, battery slurry | Corrosion resistant material (such as 316L stainless steel) |

| Pure liquid materials | Low viscosity liquids (to remove trace impurities) | Ultrasonic filter screens, precision filter separators | Medications, edible oils, cleaning agents | Leak proof sealing design required |

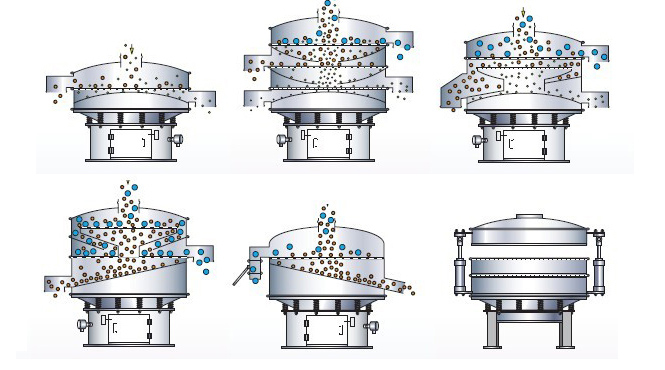

Granular materials→ are suitable for rotary vibrating screens, direct discharge screens, circular screens, etc., mainly used for grading and screening.

Particle+liquid mixture → suitable for filtration screens and cyclone screens, capable of effectively separating solids and liquids.

Pure liquid material → High efficiency filtration screen or vibrating screen is used to remove impurities and improve purity.

How does a powder separator machine work?

Powder separator machine uses YZUL vertical vibration motor as the excitation source. The eccentric weight on the upper and lower ends of the vibration motor converts the rotational motion into horizontal, vertical, and inclined three-dimensional motion, and transmits it to the screen surface of the rotary vibrating screen; the material passes through The feed inlet enters the equipment. According to different material screening requirements, the material passes through 1-5 layers of sieving with different mesh metal woven screens. In this process, a cleaning device is located under the screens of each layer. (Bouncing ball) Continuously hitting the screen through frequency vibration, so that the materials on the screen can be smoothly screened through the screen, and effectively solve the problem of material blockage. After the materials of different meshes pass through the screens of the corresponding meshes of each layer It is discharged at the discharge port of each layer, and fina lly achie ves the purpose of screening and removing impurities or filtering and grading.

Featured videos

-

Sieving quartz powder

-

Sieving alumina powder

What are the advantages of powder separator machine?

1. Wide application: sieving fine to 500 mesh or 0.028mm powder and granular, liquid materials can be filtered to 5 microns.

2. It is not easy to block the net: Bouncing ball/ultrasonic/rotating drum cleaning device can be selected to prevent the mesh from being blocked.

3. Multi-layer screening: 1-5 layers of multi-layer screening can obtain 2-6 different specifications of finished products.

4. No pollution: Fully sealed structure, no powder overflow, no liquid overflow.

5. Automation: Impurities and coarse materials are automatically discharged, and continuous operation is possible.

6. Convenient operation: The discharge port can be rotated 360°, and it only takes 3-5 minutes to replace the screen.

Technical parameters of powder separator machine

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

Other types of powder separator machine

-

Vibro Sifter

Mesh: 500 mesh (20 microns)

Capacity: 100-3300kg/h

Applications: It can be used for screening granular, granular and powdery materials, including but not limited to chemical powders, food powders, pharmaceutical raw materials, etc.

-

Ultrasonic Sieving Machine

Mesh:: 80-600 mesh

Capacity: 100-5000kg/h

Applications: 400 mesh, 500 mesh, 600 mesh flour, malt powder, coffee powder, silicon carbide, alloy powder, molybdenum powder, iron powder, powder coating, quartz powder, etc.

-

Air Flow Screen

Mesh: 80-530 mesh

Capacity: 1-5t/h

Applications: It is suitable for screening ultra-fine powder and special materials with light specific gravity, high viscosity, high fiber, static electricity and easy agglomeration.

Related cases

Food industry: flour, milk powder, glutinous rice flour, monosodium glutamate, flavoring agent, soy protein powder, corn starch, etc.

Pharmaceutical industry: Chinese medicine powder, raw materials, nucleotides, etc.

Chemical industry: aluminum powder, lead powder, electrolytic copper powder, electromagnetic powder, rubber powder, resin powder, titanium dioxide, etc.

Metallurgical industry: graphite powder, iron powder, alloy powder, etc.

| Material | Proportion | Mesh | Processing method | Capacity (kg/hr IT/hr) |

Model |

| Flour | 0.6 | 24 | Dry | 1500㎏ | DH-1000-1S |

| Wheat starch | 1 | 250 | Wet | 3200 IT | DH-1200-1S |

| Pollen | 0.4 | 12 | Dry | 100㎏ | DH-1500-1S |

| Corn starch | 0.6 | 40 | 1600㎏ | DH-1000-1S | |

| Skimmed milk powder | 0.57-0.7 | 24 | 3000㎏ | DH-1200-1S | |

| Medicine powder | 0.8 | 80 | 550㎏ | DH-800-1S | |

| Lead powder | 11.34 | 10/80 | 1000㎏ | DH-1000-2S | |

| Iron powder | 3 | 400 | 230㎏ | DH-800-1S | |

| Aluminum powder | 0.9/1.2 | 80/120 | 350㎏ | DH-800-2S |

-

Removes all oversized contamination or agglomerates from powder

-

Effectively remove dust, clumps and foreign matter in the powder

-

Remove small stones, sand or clay particles, leaves, dust and other unwanted contaminants in chili powder

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.