Aluminum Oxide Vibrating Screen

Aluminum oxide vibrating screen is a device used to screen and grade aluminum oxide powder. It separates and screens aluminum oxide powder by placing aluminum oxide powder on the screen and vibrating it, and using the aperture of the screen to control the size of the particles. Aluminum oxide, as a powdery material, has static electricity, is easy to clump, and is easy to absorb moisture. When using ordinary rotary vibrating screens for screening, the net will stick, causing the aluminum oxide powder to adhere to the screen surface, causing the net to block, affecting the screening effect. It is recommended that you choose an ultrasonic vibrating screen.

Why choose an aluminum oxide ultrasonic vibrating screen?

1. Aluminum oxide is easy to stick to the net-ultrasonic vibrating screen can solve the problem of net blocking (self-cleaning function)

Due to the installation of an ultrasonic screening system, there is no need to add any other screen cleaning device, with a self-cleaning function, the screen is not blocked, the adhered material is decomposed, and the screen material is reduced. The passing rate is 5 to 20 times higher than that of a vibrating screen without ultrasonic installation, which truly solves the screening problems such as high static electricity and easy clumping in the aluminum oxide screening process, increases its screening amount, and is very suitable for the industrial production of aluminum oxide.

2. Alumina requires a large output - Ultrasonic vibrating screen has a larger output (900kg/h)

The rotary vibrating screen uses a 100-mesh screen to screen alumina, and the processing capacity per hour can reach about 30kg, while the ultrasonic vibrating screen uses a 200-mesh screen to screen alumina powder, and the output per hour can reach about 900kg. It can be seen that the ultrasonic vibrating screen has a large screening output and better effect.

Aluminum Oxide Vibrating Screen Definition and Use

Aluminum Oxide Vibrating Screen is mainly used to screen alumina powder to ensure that its particle size meets production requirements. It can handle alumina powder of various particle sizes, ranging from 60 mesh to 600 mesh, and is suitable for chemical, metallurgical, building materials and other industries12.

Aluminum Oxide Vibrating Screen Working Principle

The working principle of the alumina vibrating screen is to use the vibration force generated by the vibration motor to make the material on the screen surface reciprocate in the horizontal, vertical or inclined direction, thereby realizing the screening of the material. By adjusting the phase angle of the vibration motor, the movement trajectory of the material on the screen surface can be changed, thereby achieving the purpose of screening1.

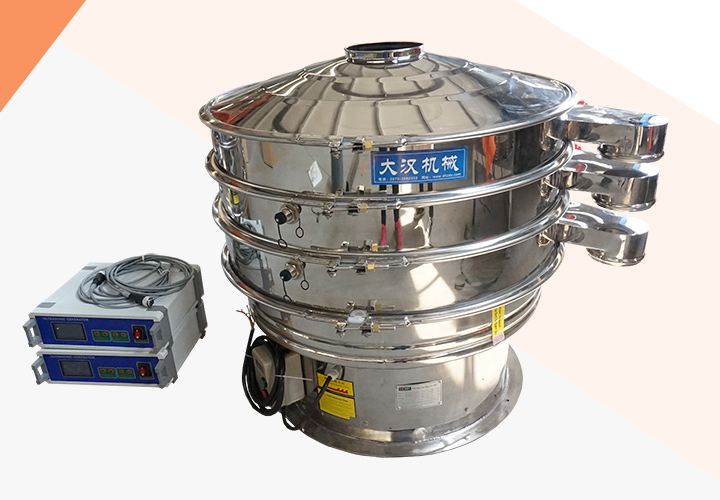

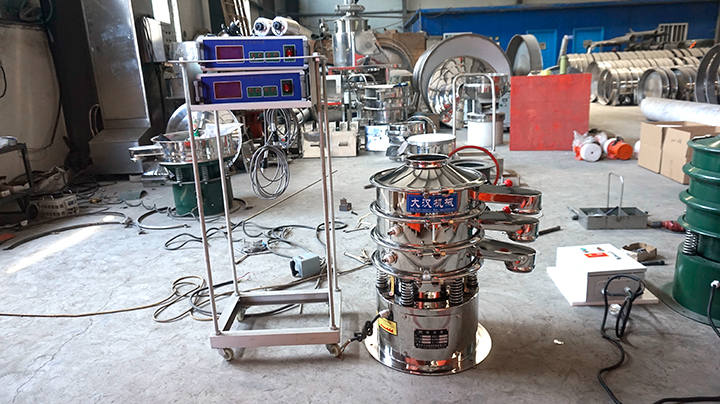

Aluminum Oxide Vibrating Screen Structural Features

Aluminum oxide vibrating screens are usually composed of screen body, vibrating motor, shock absorber, feeding device, discharging device and control system. The screen body is made of high-quality steel, with a sturdy and durable structure; the vibration motor has stable performance and strong vibration force; the shock absorber can effectively reduce the noise and vibration during the operation of the equipment, and improve the stability and service life of the equipment. 3.

Types and models

There are many types of aluminum oxide vibrating screens, including vertical vibrating screens, linear vibrating screens and ultrasonic vibrating screens. Vertical vibrating screens generate vibrations through eccentric weights, which are suitable for screening powder and mucus materials; linear vibrating screens achieve reciprocating motion of materials through high-frequency vibrations, which are suitable for grading and screening of aluminum oxide balls; ultrasonic vibrating screens can effectively break up material agglomerates and improve the passing rate through high-frequency and low-amplitude vibrations.

Aluminum Oxide Vibrating Screen Application Scenarios

Aluminum oxide vibrating screens are widely used in the production, processing and grading of aluminum oxide powder to ensure that product quality meets standards. In addition, it can also be used for screening other similar materials, such as ceramic balls, glass beads, etc.

-

Granules, powders, and paddle materials can be used

-

Can sieve ultra-fine powder down to 20 microns without clogging the sieve holes

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials, easy agglomeration....

-

Konjac fine powder ultrasonic vibrating screen

Konjac fine powder ultrasonic vibrating screen is a high-precision fine particle screening equipment. The equipment uses the up and down excitation force....

-

Paint raw materials sieve with vibro shaker

Paint raw materials sieve with vibro shaker The quality and performance of paint largely depend on the selection and screening of raw materials.....

-

Dietary Supplements for Vibrating Sieve

Dietary supplements vibrating sieve As an efficient and reliable sieving equipment, it plays an important role in the production of dietary supplements. Through high-frequency vibra ...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.