Atomized Iron Powder Vibrating Screening Machine

Atomized iron powder vibrating screening machine is a type of equipment used to separate and classify atomized iron powder particles based on their size. For iron powder, it is usually divided into five grades: ultrafine powder, fine powder, medium powder and fine powder. It is usually filtered with 80 mesh, 120 mesh and 200 mesh. From 150 to 500 μ The iron powder composed of particles of M is coarse powder with medium particle size of 44 to 150 μ m. The fine powder is 10 to 44 μ m. Superfine powder is 0.5 to 10 μ m.

Application of atomized iron powder vibrating screening machine

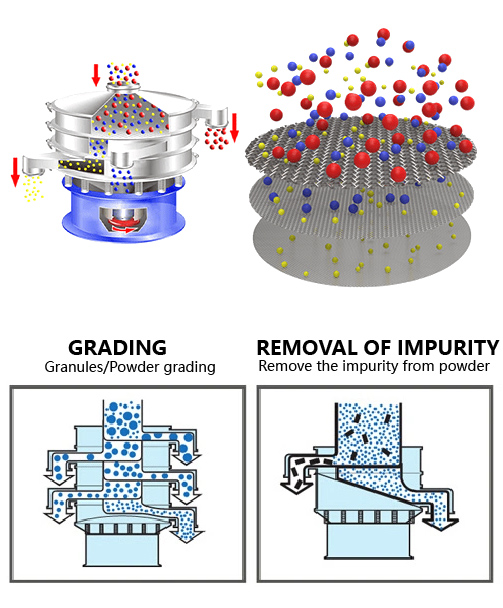

The vibrating screening machine for atomized iron powder typically utilizes a vibrating screen or sieve deck with various mesh sizes. The machine uses vibration and sieving techniques to effectively separate the iron powder particles into different fractions or grades based on their size.

Applications of atomized iron powder vibrating screening machine include:

1. Powder classification: Usually used to classify powder according to particle size. The machine can separate iron powder into different parts or grades, ensuring a consistent particle size distribution. This classification is critical for various applications requiring specific powder sizes.

2. Quality control: It can be used to check particle size distribution, remove impurities, and ensure the overall quality and consistency of iron powder.

3. Recycling and reprocessing: In some cases, atomized iron powder may undergo recycling or reprocessing processes. Vibrating screens can help separate and sort recycled or reused powders, allowing efficient use of materials and minimizing waste.

Working principle:

1. Feeding of atomized iron powder: First, the atomized iron powder to be screened is evenly put into the sieve box through the feeding port.

2. Vibration screening: When the vibrator starts to work, the rotation speed of the motor and the rotation of the eccentric block will generate a certain centrifugal force, which makes the screen box start to vibrate. The atomized iron powder passes through the screen from top to bottom under the action of the vibrating screen, the large particles are intercepted by the upper screen, and the small particles pass through the lower screen.

3. Grading and screening: The atomized iron powder can be divided into different particle sizes through the different aperture sizes of the upper and lower screens of the sieve box. Large particles are intercepted by the upper sieve to form a coarser powder, while small particles pass through the lower sieve to form a finer powder.

4. Receiving and discharging: The sieved atomized iron powder will flow out from the outlet of the sieve box and be collected into the corresponding container. At the same time, small particles pass through the deflector at the bottom and are discharged from the screening machine.

The advantages of atomized iron powder vibrating screening machine mainly include the following aspects:

1. High-efficiency screening: High-frequency vibration is used to rapidly separate materials on the screen, improve screening efficiency, and greatly reduce screening time.

2. Precise classification: The screening machine is equipped with multi-layer screens, which can classify materials according to particle size, realize multi-level classification, and obtain products that meet the requirements.

3. Widely applicable: It is suitable for screening various powdery materials, and can be widely used in metallurgy, chemical industry, food, medicine, ceramics and other industries.

4. Automatic operation: PLC control system is adopted, which can realize automatic operation and remote control, and improve production efficiency and operation convenience.

5. Energy saving and environmental protection: Adopting the principle of vibrating screening, there is no need to use a large amount of water and chemicals, which reduces the pollution to the environment and meets the requirements of energy saving and environmental protection.

Atomized iron powder vibrating screening machine is mainly used in the following scenarios:

The atomized iron powder vibrating screening machine is commonly used in several occasions, including:

1、Powder metallurgy: Atomized iron powder is widely used in powder metallurgy processes, such as compaction, sintering, and additive manufacturing. The vibrating screening machine helps ensure the particle size distribution and purity of the atomized iron powder, which is critical for achieving the desired properties and performance in powder metallurgy applications.

2、Metal injection molding (MIM): MIM is a manufacturing process that combines traditional injection molding with powder metallurgy. Atomized iron powder is often used as feedstock in MIM applications. The vibrating screening machine is employed to classify the atomized iron powder, ensuring the proper particle size range for the MIM process and enhancing the quality and consistency of the final MIM products.

3、Magnetic materials: Atomized iron powder is used in the production of magnetic materials, such as soft magnetic composites, magnetic recording media, and magnetic inks. The vibrating screening machine helps control the particle size distribution of the atomized iron powder, allowing for the customization of magnetic properties and ensuring optimal performance in magnetic applications.

4、Surface coating and painting: Atomized iron powder can be used as a pigment or filler in surface coating and painting applications. The vibrating screening machine assists in separating the iron powder particles based on their size, ensuring a consistent and uniform distribution in the coating or paint formulation.

These are some of the common occasions where the atomized iron powder vibrating screening machine is used. Its role in ensuring particle size distribution, quality control, and customization makes it an essential tool in industries that rely on atomized iron powder for various applications.

-

Innovative high-enclosed sieving machine can accurately ...

-

The screen is fine to 500 meshes, and it is not easy to be blocked ...

-

Remove small stones, sand or clay particles, leaves, dust and other unwanted contaminants in chili powder...

-

How much is an abrasive automatic sieving machine?

Abrasive automatic sieving machine is a commonly used industrial powder sieving equipment ...

-

Toner ultrasonic vibration screening machine

Toner ultrasonic vibration screening is a device that uses the principle of ultrasonic vibration for screening ...

-

Peanut Flour Vibrating Screening Machine

Peanut flour vibrating screening machine is a kind of equipment used to sieve peanut powder ...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.