Carbon steel vibrating screen

![[field:title/]](/uploads/allimg/250113/6-2501131R11DA-lp.png)

Callback

Carbon steel vibrating screen is a screening equipment widely used in industrial production, mainly used for removing impurities and grading dry powder and granular materials.

Processing capacity: 500kg

Power: 0.25kw

Number of layers: 1-5 layers

Feed particle size: <10mm

Mesh size: 5-500 mesh

Productivity: 100 kg – 3 tons/hour

Features: low production cost, wide range of applicable materials

What is Carbon Steel Vibrating Screen?

Carbon steel vibrating screen is a device that uses the principle of vibration to screen granular or powdered materials. Its main structural components are made of carbon steel. Carbon steel is an iron-carbon alloy with a carbon content of less than 2.11%. It has good strength, toughness and processing properties, which enables the carbon steel vibrating screen to withstand a certain material weight and vibration impact.

Carbon steel vibrating screen video

How does Carbon Steel Vibrating Screen work?

Carbon steel vibrating screen generates vibrations through the exciter, causing the screen box to vibrate horizontally or obliquely. The material on the screen surface is affected by the excitation force and gravity, jumping on the screen surface and moving forward. Materials larger than the screen hole are retained on the screen surface, and materials smaller than the screen hole fall through the screen into the next layer or are discharged.

What types of Carbon Steel Vibrating Screens are there?

1、Circular carbon steel vibrating screen

Structural features: The screen box and screen are circular. The structure of this shape of carbon steel vibrating screen is relatively symmetrical and the force is evenly distributed during operation.

Movement path: The movement path is relatively regular, which is conducive to fine screening of materials with small particle size differences.

Advantages: And due to its circular motion characteristics, the distribution of materials on the screen is relatively uniform, and local accumulation is not easy to occur.

Application scenarios: Widely used in the screening of materials with high precision requirements in fine chemicals, food, medicine and other industries.

2、Square carbon steel vibrating screen

Structural features: The screen box and screen are square or rectangular, and the screening area is relatively large, which can handle more materials.

Movement path: The movement trajectory is relatively complex, and the square screen is prone to stress concentration at the four corners

Advantages: The strength and installation firmness of the screen are relatively high, which is more conducive to breaking up the agglomerated materials.

Application scenarios: It is widely used in the mining and building materials industries.

Features of Carbon Steel Vibrating Screen

1. High cost-effectiveness: Carbon steel, as a common metal material, is relatively cheap, making the manufacturing cost of carbon steel vibrating screen lower than some vibrating screens made of stainless steel or other special alloy materials.

2. Good strength and durability: Carbon steel material itself has good strength and toughness, and can withstand large impact force and material weight. Under normal use and maintenance conditions, carbon steel vibrating screen can operate stably for a long time and is not easy to damage.

3. Good screening performance: Through reasonable vibration parameter setting and screen selection, carbon steel vibrating screen can effectively screen a variety of materials. It can accurately classify materials according to particle size to meet the production needs of different industries.

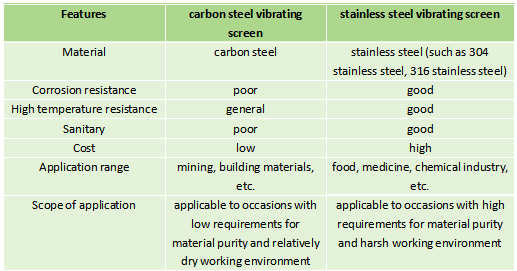

Comparison between carbon steel vibrating screen and stainless steel vibrating screen

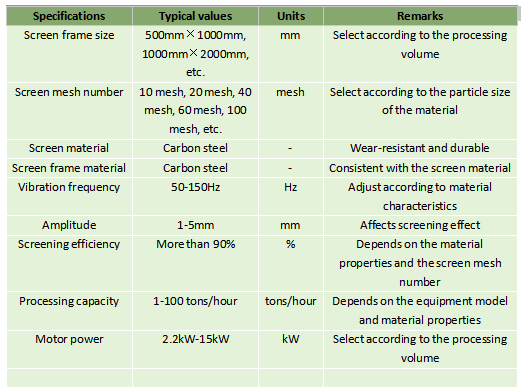

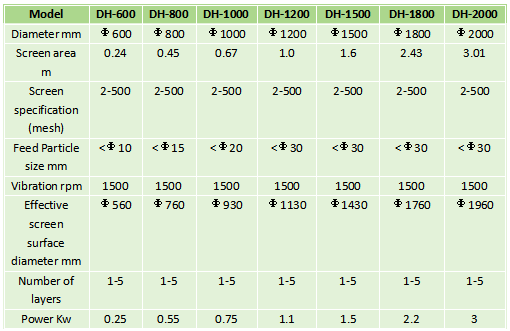

Specifications of carbon steel vibrating screen

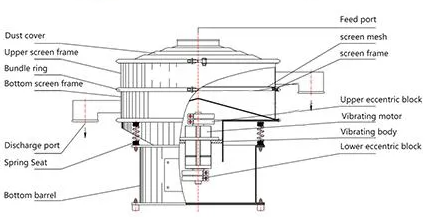

Structure of Carbon Steel Vibrating Screen

Screen box: The screen box is the core component of the vibrating screen, usually welded with carbon steel plates, with high strength and rigidity.

Screen: Installed on the screen box for screening materials. The material, mesh and hole type of the screen are selected according to the characteristics of the material and the screening requirements.

Vibrator: Provides a vibration source, usually an electric vibration motor.

Suspension device: Suspend the screen box on the frame to make the screen box vibrate.

Base: Support the entire equipment and provide an installation foundation.

Parameters of carbon steel vibrating screen

Application scenarios of carbon steel vibrating screen

1. Building materials industry: used to screen building materials such as sand and gravel, and separate materials of different particle sizes to meet the requirements of material particle size in construction. For example, in a concrete mixing station, a carbon steel vibrating screen can screen out coarse sand and fine sand that meet the requirements for the production of concrete of different strength grades.

2. Mining field: Widely used in the preliminary screening and grading of ores. The mined ore can be classified according to particle size to provide suitable raw materials for subsequent beneficiation and processing procedures.

3. Agricultural processing: used for screening of agricultural products such as grains and seeds. For example, at grain purchasing stations, carbon steel vibrating screens can remove impurities and empty grains from grains to ensure the quality of grains; in seed companies, they are used to screen out plump and uniformly sized seeds to improve the germination rate of seeds.

Carbon steel vibrating screen customer case

Carbon steel vibrating screen supplier

-

Screening and filtering of particles, powders, liquids and other materials

-

Filter wheat flour and remove unwanted particles to ensure product quality

-

Diamond Vibrating Screen

Diamond vibrating screen is a device used for screening and grading diamond particles. Through vibration force and screen structure ...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials, easy agglomeration, low melting point, ...

-

Sugarcane Juice Bioethanol Vibro Sifter

Sugarcane Juice Bioethanol Vibro Sifter is a device for filtering sugarcane juice, mainly used for sugarcane juice filtration in bioethanol industry. ...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.