Cocoa Separation Machine

![[field:title/]](/uploads/211117/1-21111G609433X.jpg)

Callback

| Mesh Size: | 2-500 mesh |

| Capacity: | 100-3300kg/h |

SS304 or 316L stainless steel material ensures no material deposits and zero possibility of material contamination.

Small footprint to fit into any production line

Closed construction to prevent dust and smoke

Introduction of cocoa separation machine

Cocoa separation machine is a special equipment for separating cocoa beans and cocoa pods, it is mainly used to separate cocoa beans and husks, it can also classify cocoa beans of different sizes, you can achieve 6 different classifications in one operation, because it Up to 5 layers can be established.

The Cocoa separation machine is manufactured according to the highest standards in the food industry, namely SUS304 or 316L stainless steel, and adopts a fully enclosed structure to ensure dust-free operation and a leak-proof system. In addition, all welded joints of the screening machine are seamless, providing hygienic and pollution-free operate.

Cocoa separation machine working flow

Acceptance and storage of cocoa beans—feeding and cleaning—roasting—separation of kernel shells—coarse grinding and slurry storage—sterilization and alkalization—fine grinding—homogenization—pressing—milling. Roasted cocoa beans are generally separated into the kernel shell. This process is an important part of producing high-quality cocoa powder. After being separated from the kernel shell, the outer skin of the cocoa beans is all brushed off, and only the cocoa kernels enter the next process. Cocoa beans that have been coarsely ground generally reach a 200-mesh pass rate of more than 95%.

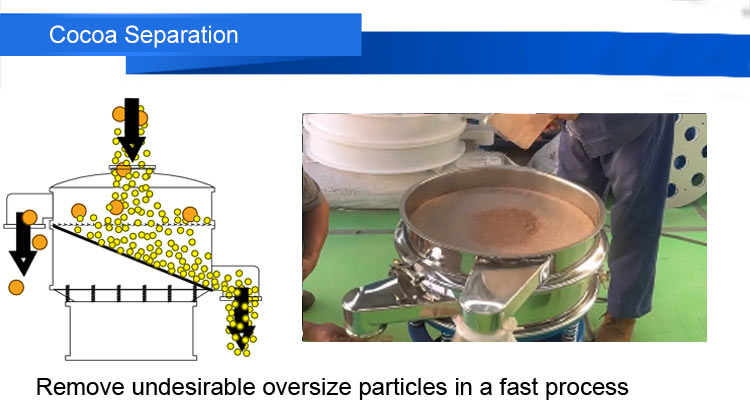

The coarsely ground cocoa powder has the characteristics of oiliness, adhesion, and clumping. It is difficult to sieve with ordinary vibrating sieves, mainly because the oily screen is more serious. After the experiment, the ultrasonic vibrating sieve solved this problem very well. During the working process of the ultrasonic vibrating sieve, the cocoa powder on the sieve is always in a suspended state, which effectively avoids the clogging of the mesh by the material and effectively solves the problem. Cocoa powder bundling problem.

Application of cocoa separation machine

1. Cocoa powder dust removal and impurity removal: remove various types of foreign objects and unwanted particles from cocoa powder, and accurately remove super large pollutants in coffee beans, so that when cocoa powder reaches the final stage of the production line, all impurities are removed. has been removed to ensure high quality.

2. Cocoa beans removal and classification: Cocoa separation machine can remove branches, stones and other debris from cocoa beans, and can separate cocoa beans into 2-6 different grades according to customer requirements.

Featured videos

-

Cocoa bean separation

-

Sieving cocoa powder

Benefits of cocoa separation machine

1. The equipment that can sieve the size and particle size of cocoa beans and cocoa powder. After sieving, the materials are classified according to size, which is convenient for further use.

2. Uninterrupted discharge of oversized particles and foreign matter. Within one hour, 1300 kg of cocoa powder will be screened through a 2mm sieve, and the maximum processing capacity can reach 3300 kg/hour.

3. In order to support the application in the food processing industry, the hose and gasket are made of standard food-grade silicone and meet the requirements of the Food Safety Authority.

4. Up to 4 layers of screens can be loaded to achieve precise separation of each layer, and 5 levels of separation can be completed in one operation.

5. Without any tools, it can be easily disassembled and cleaned, reducing downtime and improving operator safety, making it an excellent screening solution for reliable quality control of cocoa product lines.

6. Equipped with 4 casters, it can be moved back and forth in different workshops by pallet or forklift.

Technical parameters of cocoa separation machine

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

Related cases

| Raw Material | Mesh Size | Model | Method | Capacity (kg/hr t/hr) |

| Cocoa powder | 250 | DH-1200-1S | Wet | 3200 t/hr |

| Cocoa beans | 20/60 | DH-1500-1S | dry | 8000㎏ |

| Cocoa syrup | 32 | DH-1000-1S | Wet | 8000 IT |

-

The screen is fine to 500 meshes, and it is not easy to be blocked.

-

You can achieve 6 different levels in one operation, because it can build up to 5 layers.

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.