Detergent vibrating screen

Detergent vibrating screen is a screening device commonly used in washing powder production lines. It is used to screen and grade impurities and uneven particles in detergent raw materials. As a common household cleaning product, the quality of detergent directly affects the cleaning effect of clothes. In order to ensure the quality of detergents, multiple screenings are often required during the production process to remove impurities, control particle size, and ensure the uniformity and fluidity of the product. Screening through the vibrating screen can separate powdered or granular raw materials according to different particle sizes to ensure product quality and production efficiency.

Video of detergent vibrating screen

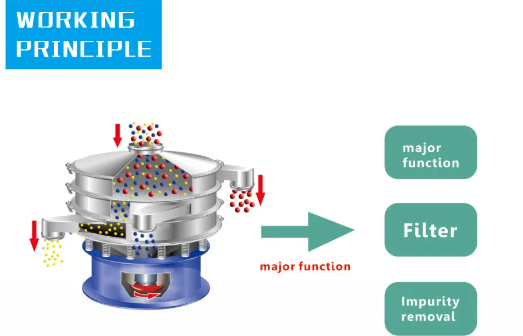

Working principle of detergent vibrating screen

1. Vibration generation: Vibration is generated by the vibration motor, which makes the screen box produce horizontal reciprocating motion or three-dimensional motion.

2. Detergent particle movement: Detergent particles on the screen surface are subjected to the combined action of the excitation force and gravity, producing jumping motion.

3. Screening separation: Detergent particles smaller than the screen hole pass through the screen, while the detergent particles larger than the screen hole are retained on the screen surface.

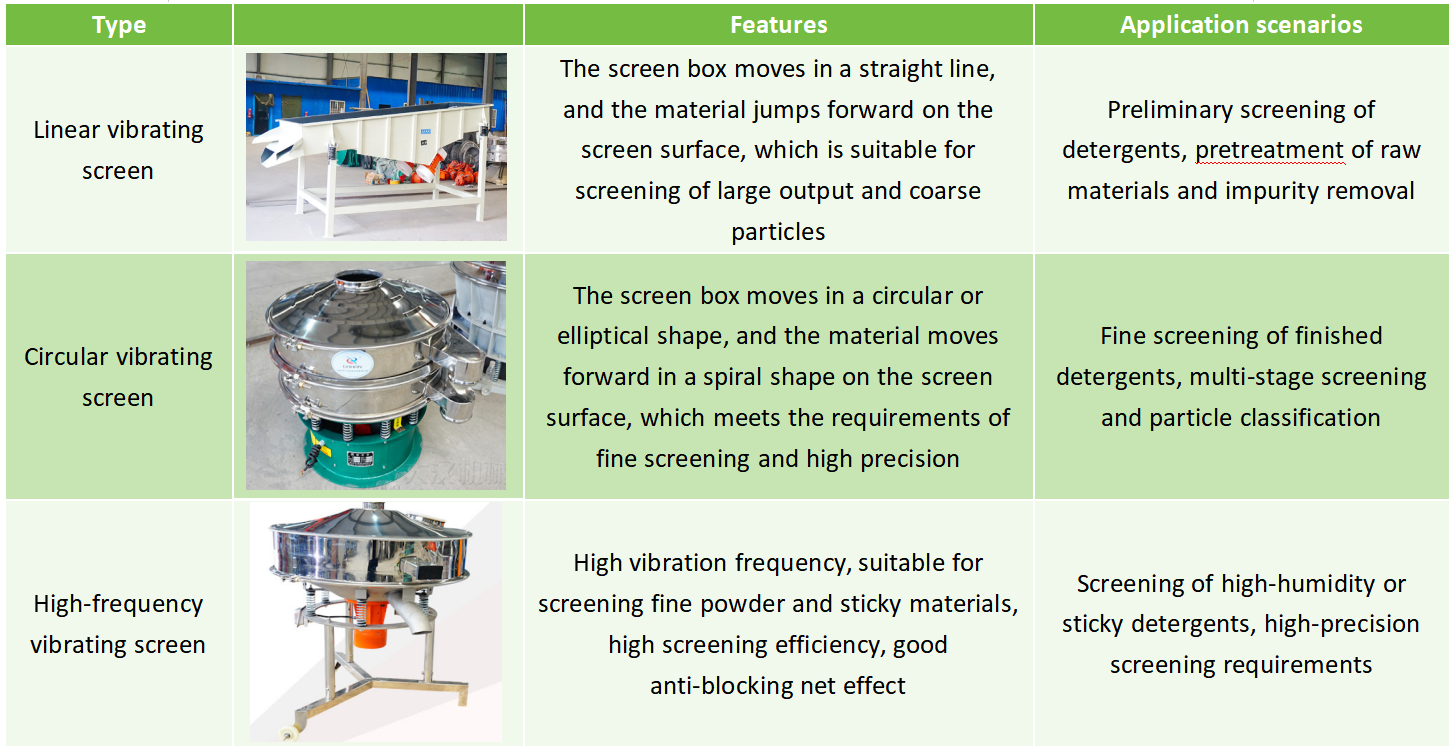

Classification of detergent vibrating screen

Advantages of detergent vibrating screen

1. High-precision screening: It can accurately separate detergent particles of different particle sizes to ensure the uniformity of the product's particle size and quality stability. For detergents with a particle size of 50-100 mesh, the vibrating screen can effectively screen out particles that do not meet the requirements, so that the product's particle size qualification rate reaches more than 95%.

2. Applicable to a variety of detergents: When producing powdered detergents such as laundry detergent and dishwashing powder, it can remove lumps and impurities; for granular cleaners such as pipe dredging agents, it can be graded by particle size; for slurry glass cleaners, it can also be filtered and impurities removed to remove possible solid impurities.

3. Low-fault operation: The vibrating screen has no complex transmission mechanism and vulnerable parts, and the probability of failure during operation is low. Equipped with advanced automatic control systems and protection devices to ensure that the equipment operates stably in a safe state, improving the continuity and reliability of production.

4. Energy-saving design: The vibrating motor of the vibrating screen adopts high-efficiency and energy-saving motor technology to ensure the screening effect and reduce energy consumption. Compared with traditional screening equipment, it can save energy by about 20%-30%, which meets the requirements of environmental protection and energy saving.

Application of detergent vibrating screen

1、Raw material screening: In the first step of washing powder production, various raw materials need to be screened to remove impurities such as stones, sawdust, etc. This helps to ensure the smoothness of the production process and the purity of the product.

2、Intermediate product screening: In the production process of washing powder, some intermediate products such as granular additives are produced, which also need to be screened to control the particle size.

3、Finished product screening: This is the last step in the production process of washing powder. Through the vibrating screen, the lumps and large particles in the finished washing powder can be removed to ensure the uniformity and fluidity of the product and improve the quality of the product.

Precautions for selecting detergent vibrating screens

1. Equipment inspection: Before use, check whether the screen is intact, whether the bolts and other fasteners are loose, whether the motor is normal.

2. Operation specifications: The material should be evenly fed to avoid local overload affecting the screening effect. The feeding speed is moderate to prevent blockage or insufficient screening.

3. Cleaning and maintenance: Clean the screen and the interior in time after each use to prevent residue from affecting the next use.

4. Safety matters: Check the electrical circuit regularly to prevent leakage or short circuit.

5. Environmental requirements: Ensure that the working area is ventilated to avoid the accumulation of detergent volatiles.

6. Shutdown: Stop feeding before shutting down, and shut down after the screen surface material is cleaned.

Detergent vibrating screens play a vital role in the detergent production process. Through screening, the quality of detergents can be guaranteed and the competitiveness of products can be improved. When choosing a detergent vibrating screen, the appropriate model should be selected according to specific production needs.

-

High-precision screening of materials is achieved through a unique screening method

-

Filter flour and remove unwanted particles to ensure product quality

-

Moxa linear vibrating screen

Concrete vibrating screen is a screening equipment used in concrete production. It is mainly used to screen, grade and remove impurities from ...

-

Steel fiber vibrating screen

Steel fiber vibrating screen is a kind of vibrating screening equipment specially used for...

-

Soy product vibrating screen

Soy product vibrating screen is a screening device specially designed for the production of...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.