Flat gyratory screen

![[field:title/]](/uploads/241012/1-241012162234A5.jpg)

Callback

| Power:5.7-7.5kw | Screen specifications: 2-500 mesh |

Distribute the material on the entire screen surface.

Multi-level material classification to remove unqualified materials.

Reciprocating motion at the discharge end.

Flat gyratory screen is a screening equipment. Its working principle is to use the screen body to perform a plane rotation motion, so that the material can reciprocate on the screen surface to increase the number of contacts between the material and the screen and improve the screening efficiency. Especially for the screening of urea with strong hygroscopicity, high viscosity, easy to block holes and stick to the screen. Due to the adoption of the plane rotation motion principle, the dynamic-static ratio and basic dynamic load of the equipment are effectively reduced.

Features of flat gyratory screen

The screen boat is driven by belt drive, with partial weight balance and low noise. The tail support of the screen boat is an improved elastic support with small vibration and low noise.

The reinforced machine base ensures that the equipment runs more smoothly. It can also adopt a hanging structure according to the actual site conditions to meet the needs of customers for transformation.

Working principle of flat gyratory screen

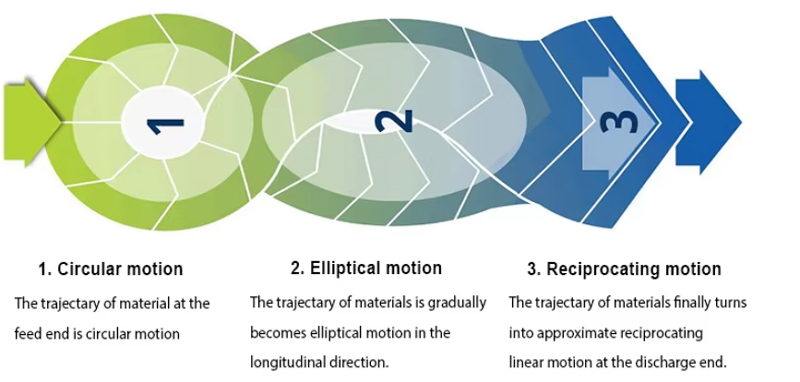

The motion trajectory of the screen body of the flat gyratory screen is horizontal circular motion at the feed end, gradually changes to elliptical motion in the length direction, and finally changes to approximately reciprocating linear motion at the discharge end. This motion trajectory can make the material reciprocate on the screen surface, thereby achieving the screening effect.

The gyratory reciprocating motion gradually transitions along the length of the equipment. The gyratory motion starts from the head, then moves to elliptical motion in the center, and returns to reciprocating motion when approaching the end.

1. Circular motion at the feed end.

Distribute the material over the entire screen surface.

Multi-level classification of materials to remove unqualified materials.

2. Change to elliptical motion in the center.

High output actively conveys materials forward.

3. Reciprocating motion at the discharge end.

Improve screening efficiency.

No vertical up and down jumps, ensuring continuous contact between the material and the screen surface.

Flat gyratory screen model

| Model | Screen area(m2) | Number of layers | Feed size(mm) | Amplitude(s) | Speed(r/min) | Power(kW) |

| HXS-1224 | 1200×2400 | 1~3 | ≤15 | 75~90 | 1450 | 5.5 |

| HXS-1236 | 1236×3600 | 1~3 | ||||

| HXS-1530 | 1500×3000 | 1~3 | ||||

| HXS-1536 | 1500×3600 | 1~3 | 750 | |||

| HXS-1836 | 1800×3600 | 1~3 | ≤20 | 7.5 | ||

| HXS-1840 | 1800×4000 | 1~3 | ||||

| HXS-2040 | 2000×4000 | 1~3 | 11 |

Application of flat gyratory screen

In the fertilizer production process, the flat gyratory screen can efficiently screen the raw materials, remove impurities and particles, and ensure the quality and purity of the product. In the production of ceramsite, the flat rotary screen can finely screen the raw materials, ensure the uniformity and stability of the ceramsite, and improve the quality and market competitiveness of the product. In the pharmaceutical industry, the flat rotary screen can finely screen the drug raw materials, remove impurities and particles, improve the purity and stability of the drug, and ensure the safety of the patient's medication. In addition, in the fields of metallurgy, chemical industry, grain processing, etc., the flat rotary screen also plays an irreplaceable role.

flat gyratory screen is right fit for stationary bark and green waste recovery

-

Millet vibrating sieve is widely used in millet processing industry, including millet processing plants, rice flour plants, rice processing plants and other places.

-

Vibro Sifterfor Powdered Sugar

Powdered sugar vibro sifter is a device for screening sugar powder. It uses vibration to divide sugar

-

Powder Coating Ultrasonic Sieving Machine

The screening accuracy can be increased by 1-70%, and the output can be increased by 0.5-10 times.

-

How to Apply Powder Coating Ultrasonic Sieving Machine

Powder coating ultrasonic sieving machine is a fine powder sieving machine with relatively perfect te ...

-

Sunflower seeds screening machine

Sunflower seed screening machine, also known as sunflower seed vibrating screen or separator, is a special equipment ...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials, easy agglomeration ...

-

Sweet potato powder screening machine

The Sweet potato powder screening machine effectively screens, filters and removes sweet potato starch to ensure the quality ...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.