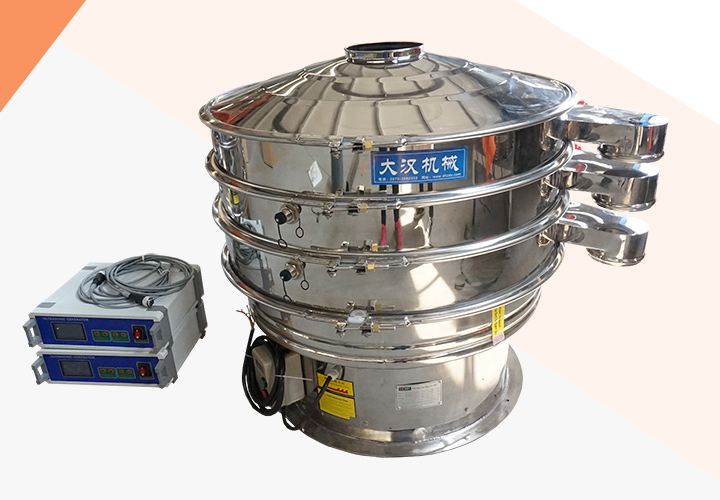

Sunflower seeds screening machine

sunflower seeds screening machine, also known as a sunflower seeds vibrating screen or separator, is a specialized equipment used in the agricultural and food processing industries to separate impurities, debris, and undersized or oversized particles from sunflower seeds. This machine plays a crucial role in ensuring the quality and purity of sunflower seeds before further processing or packaging.

Features of Sunflower Seeds Screening Machine

Multiple Layers: Sunflower seeds screening machines often have multiple layers of screens to efficiently separate different sizes of materials.

Adjustable Settings: These machines come with adjustable settings for vibration intensity, screen inclination, and other parameters to optimize the screening process.

High Efficiency: Sunflower seeds screening machines are designed for high efficiency, ensuring a thorough separation of impurities from the seeds.

Easy Maintenance: Many screening machines are designed for easy maintenance, with quick access to screens and components for cleaning and replacement.

Durable Construction: These machines are typically constructed from high-quality materials to withstand the rigors of continuous operation in agricultural and food processing environments.

Customizable: Some machines offer customization options such as different screen sizes and configurations to meet specific processing requirements.

Working Principle of Sunflower Seeds Screening Machine

Vibration: The machine uses vibration to separate the sunflower seeds from impurities. As the machine vibrates, the seeds move along the screen surfaces, allowing smaller particles and impurities to fall through the screens.

Screening Layers: The sunflower seeds pass through multiple layers of screens with different mesh sizes. Each screen layer is designed to capture specific sizes of particles, ensuring a thorough separation process.

Adjustable Parameters: Operators can adjust the vibration intensity, screen inclination, and other settings to optimize the screening process based on the characteristics of the sunflower seeds.

Separation: The screens on the machine effectively separate the sunflower seeds from impurities such as dust, debris, and undersized or oversized particles. The separated materials are collected for further processing or disposal.

Applications of Sunflower Seeds Screening Machine

Seed Cleaning: Sunflower seeds screening machines are used for cleaning and grading sunflower seeds before packaging or further processing.

Quality Control: These machines help ensure the quality and purity of sunflower seeds by removing impurities and defective seeds.

Seed Processing Plants: Sunflower seeds screening machines are commonly used in seed processing plants, agricultural facilities, and food processing industries.

Agricultural Operations: Farmers and agricultural producers use screening machines to prepare sunflower seeds for sale or storage.

Benefits of Sunflower Seeds Screening Machine

By removing impurities and defective seeds, the screening machine helps maintain the quality and purity of sunflower seeds.

The machine streamlines the screening process, saving time and labor compared to manual methods.

Sunflower seeds screening machines can handle large volumes of seeds, increasing overall productivity in processing operations.

Investing in a screening machine can lead to cost savings by reducing waste and improving the efficiency of seed processing operations.

The machine provides consistent and reliable results in separating impurities from sunflower seeds, ensuring uniformity in the final product.

sunflower seeds screening machine is an essential piece of equipment in the agricultural and food processing industries for ensuring the quality, purity, and uniformity of sunflower seeds. By utilizing this specialized equipment, businesses can streamline their seed processing operations, improve product quality, and enhance overall efficiency in the production process.

-

Granules, powders, and paddle materials can be used

-

Can sieve ultra-fine powder down to 20 microns without clogging the sieve holes

-

Graphite Powder Sieving Machine

It can be used in single layer or multiple layers, and 6 different grades of graphite ...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials, easy agglomeration....

-

Konjac fine powder ultrasonic vibrating screen

Konjac fine powder ultrasonic vibrating screen is a high-precision fine particle screening equipment. The equipment uses the up and down excitation force....

-

Paint raw materials sieve with vibro shaker

Paint raw materials sieve with vibro shaker The quality and performance of paint largely depend on the selection and screening of raw materials.....

-

Dietary Supplements for Vibrating Sieve

Dietary supplements vibrating sieve As an efficient and reliable sieving equipment, it plays an important role in the production of dietary supplements. Through high-frequency vibra ...

-

Aqua Feed For Ultrasonic Vibrating Screen

The aquatic feed ultrasonic vibrating screen uses advanced ultrasonic technology to achieve an efficient screening process through high-frequency weak vibration. Compared with tradi ...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.