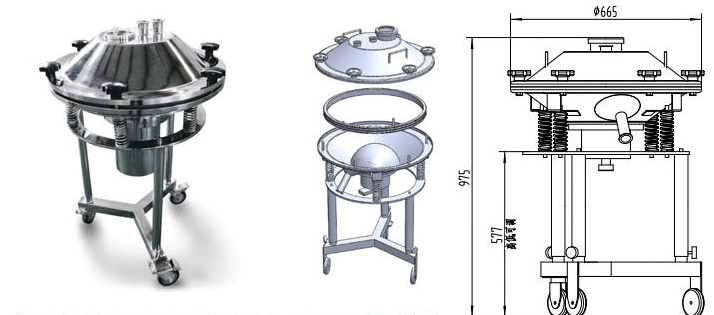

Glaze vibrating screen

Plastic sheet vibrating screen is a device used to screen glazes. It is mainly used in related industries such as ceramics, glass, enamel, etc. that require the use of glazes. It separates the particles in the glaze by size through vibration, and removes impurities, particles that are too large or too small in the material to ensure the purity and uniformity of the glaze, thereby improving the quality of ceramic products.This equipment plays a key role in the ceramic production process, helping ceramic manufacturers improve production efficiency, reduce costs, and ensure that the ceramic products produced have stable quality.

Video of glaze vibrating screen

What is the principle of glaze vibrating screen?

A high-frequency vibration motor is used as the vibration source to screen the material through the screen. The vibration force generated by the high-frequency vibration motor is transmitted to the screen box and the screen by the vibrator, so that the material produces high-speed, small-amplitude vibration on the screen. Smaller particles will pass through the screen and enter the next level of the screen, while larger particles will be blocked on the screen, thus achieving the effect of screening and separation.

Functions of glaze vibrating screen

Remove impurities: separate large particles, lumps and impurities in the glaze to ensure the purity of the glaze.

Grading and screening: According to production needs, the glaze is graded by particle size to meet different process requirements.

Improve uniformity: ensure that the glaze particles are evenly distributed to avoid color difference or uneven surface during coating.

Improve efficiency: automate the screening process, reduce manual operations, and improve production efficiency.

What are the advantages of glaze vibrating screen?

1. Improve glaze quality: There are often various granular impurities in ceramic glaze, such as particles, fine quartz sand, etc. The glaze vibrating screen can effectively screen these impurities out of the glaze to ensure the purity and quality of the glaze.

2.Improve glaze quality: Through the screening effect of the glaze vibrating screen, the glaze particles can be distributed more evenly, avoiding large particles or lumps in the glaze, thereby improving the uniformity and stability of the glaze.

3. Optimize production process: The glaze vibrating screen can help ceramic manufacturers optimize the production process, ensure that the quality of the glaze meets the requirements during the production process, and improve production efficiency and product quality.

4. Product quality control: The quality of ceramic products depends to a large extent on the quality of the glaze. Screening and filtering the glaze through the glaze vibrating screen can effectively control the quality of the glaze and improve the quality stability of the final product.

Application of glaze vibrating screen

1. Raw material screening: Before glaze preparation, various raw materials (such as feldspar, kaolin, quartz, etc.) are screened to remove impurities and ensure the purity of raw materials.

2. Screening after glaze mixing: The prepared glaze is screened to remove agglomerates and impurities generated during the mixing process to ensure the uniformity of the glaze.

3. Screening before glaze spraying: Before spraying the glaze on the ceramic body, a fine sieve is performed to remove possible larger particles to ensure the smoothness of the glaze surface.

4. Screening for glaze recovery: In the process of glaze production, some waste glazes will be generated, and the useful components in them can be recovered by screening.

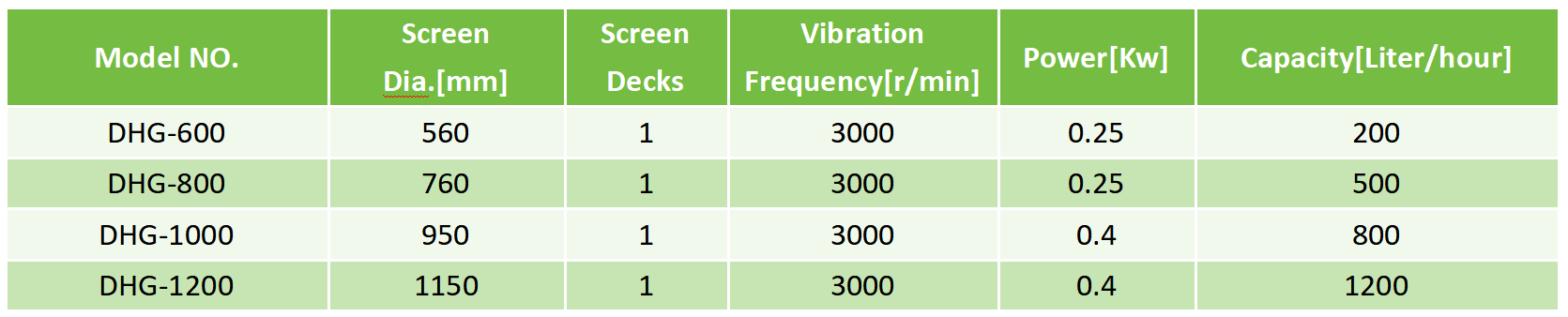

Technical parameters of glaze vibrating screen

How to fix a glaze vibrating screen?

Troubleshooting: Before repairing, determine the specific problem of the vibrating screen. Common problems include no vibration or weak vibration, uneven screening, abnormal noise or excessive vibration, material leakage and reduced screening efficiency.

Daily maintenance suggestions: Clean the screen regularly and clean the screen after each use to prevent glaze accumulation; check the wearing parts, check the screen, bearings and seals regularly, and replace the worn parts in time Lubricate the moving parts: Add lubricating oil to the bearings and vibrating motor regularly to reduce wear. Ensure that the vibrating screen is installed smoothly to avoid failures caused by imbalance.

Preventive measures: Choose the appropriate screen mesh according to the characteristics of the glaze. Avoid overload operation and control the feed amount. Check the equipment regularly to find and solve problems in time.

Plastic sheet vibrating screen plays a vital role in the ceramic production process. Screening can improve the purity and uniformity of the glaze, thereby improving the quality of ceramic products. When choosing a glaze vibrating screen, you should choose the appropriate model according to the specific production needs.

-

High-precision screening of materials is achieved through a unique screening method

-

Filter flour and remove unwanted particles to ensure product quality

-

Plastic sheet vibrating screen

Plastic sheet vibrating screen is a kind of equipment specially used for screening plastic...

-

Soy product vibrating screen

Detergent vibrating screen is a screening device commonly used in washing powder production...

-

Moxa linear vibrating screen

Concrete vibrating screen is a screening equipment used in concrete production. It is mainly used to screen, grade and remove impurities from ...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.