Grading vibrating sieve

![[field:title/]](/uploads/allimg/250114/6-250114144114R3-lp.png)

Callback

Grading vibrating sieve is a machine that uses a vibrating screen surface to grade mixtures of different particle sizes according to particle size.

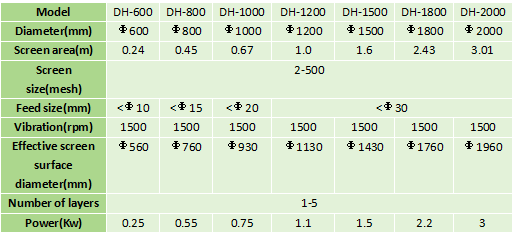

Processing capacity: 8-20t

Screen specifications: 2-500 mesh

Material: carbon steel, stainless steel, plastic

Number of layers: 1-5 layers

Selling points:

1. Wide screening range, can screen powder, granules, mucus and other materials

2. Small size does not take up space, easy to move, and the outlet can be adjusted 360° at will

3. One material can be sorted into 2-6 different particle size specifications

What is Grading vibrating sieve?

Grading vibrating sieve is a mechanical device that uses the principle of vibration to screen and grade materials of different particle sizes. Through the different apertures of the screen, particles of different sizes are separated to achieve the purpose of grading.

Grading vibrating sieve video

How does Grading vibrating sieve work?

Through reasonable screen surface inclination angle and screen mesh aperture, the screen surface angle is adjustable, and the screen surface is cleaned by chain to strengthen screening and ensure the grading effect. When the vibrator vibrates, the material moves on the screen, and the smaller particles pass through the pores of the screen, while the larger particles are blocked on the screen, thereby achieving material screening and grading.

Application of Grading vibrating sieve

Grading vibrating sieve is widely used in chemical, mining, metallurgy, building materials, food and other industries. It can be used to sieve various dry powders, particles, liquids and other materials. Especially in the coal, ore, cement and other industries, grading vibrating sieve plays a very important role.

What types of Grading vibrating sieves are there?

Circular vibrating sieve

The sieve box moves in a circular motion, and the material moves in a circular motion on the sieve surface

Features: large processing capacity, simple structure, high screening efficiency

Advantages: strong adaptability, long sieve life

Scope of application: widely used in mining, building materials, metallurgy and other industries, can handle wet materials and sticky materials

Linear vibrating sieve

The sieve box moves in a linear reciprocating motion, and the material moves in a linear motion on the sieve surface

Features: high screening accuracy and strong adaptability.

Advantages: large processing capacity, not easy to clog, high screening accuracy

Scope of application: widely used in food, medicine, chemical and other industries, used for screening powder and granular materials, and can handle a variety of materials.

High-frequency vibrating sieve

High-frequency vibration is generated by high-frequency vibration motor, so that the material jumps quickly on the sieve surface

Features: high screening accuracy, fast screening speed, high vibration frequency

Advantages: suitable for occasions with high requirements for screening accuracy

Scope of application: widely used in electronics, medicine, food and other industries, can be used to handle sticky materials

Advantages of Grading vibrating sieve

1. Solve the problem of unclear material stratification: Use a uniform feeding device to ensure that the material can be evenly distributed on the screen surface, avoid local accumulation or uneven thickness of the material on the screen surface, and facilitate the stratification and screening of the material.

2. Deal with the problem of wet and sticky materials: Grading vibrating sieve can increase the vibration intensity so that the material is subjected to greater impact and vibration force on the screen surface, thereby overcoming the viscosity and surface tension of the material, making it easier to loosen and pass through the screen.

3. Deal with the problem of material blockage: Through high-frequency vibration, the material on the screen surface is in a state of constant jumping and rolling, reducing the residence time of the material at the screen hole, thereby reducing the possibility of the material blocking the screen hole.

4. Reduce wear and noise problems: Use shock-absorbing materials and shock-absorbing structures in the support device and connection parts of the equipment to reduce the transmission of vibration to the foundation and the surrounding environment, and reduce noise. Take sound insulation measures for noise-generating components such as vibration motors to further reduce the noise during equipment operation.

Technical parameters of Grading vibrating sieve

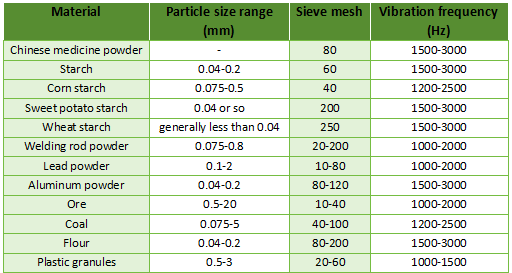

Applicable materials of Grading vibrating sieve

The mesh number of the graded vibrating screen ranges from 2 to 500 meshes. Generally speaking, the larger the mesh number, the smaller the sieve hole, and the finer the material that can be screened. The graded vibrating screen is suitable for screening scenarios with high requirements for material fineness. The mesh number required for screening different materials varies.

Customer cases of Grading vibrating sieve

Grading vibrating screen supplier

-

Millet vibrating sieve is widely used in millet processing industry, including millet processing plants, rice flour plants, rice......

-

Vibro Sifterfor Powdered Sugar

Powdered sugar vibro sifter is a device for screening sugar powder. It uses vibration to divide sugar

-

Powder Coating Ultrasonic Sieving Machine

The screening accuracy can be increased by 1-70%, and the output can be increased......

-

How to Apply Powder Coating Ultrasonic Sieving Machine

Powder coating ultrasonic sieving machine is a fine powder sieving machine with relatively perfect te ...

-

Sunflower seeds screening machine

Sunflower seed screening machine, also known as sunflower seed vibrating screen or separator, is a special equipment ...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials, easy agglomeration ...

-

Sweet potato powder screening machine

The Sweet potato powder screening machine effectively screens, filters and removes sweet potato starch to ensure the quality ...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.