Moxa linear vibrating screen

Moxa linear vibrating screen is a screening device specially designed for moxa processing. It is mainly composed of vibration motor, screen box, screen, damping spring and other components. Through the principle of linear vibration, impurities and dust in the moxa are separated, thereby improving the purity and quality of the moxa. The moxa linear vibrating screen plays a vital role in the moxa processing process and can effectively improve the production efficiency of moxa. By choosing a suitable moxa linear vibrating screen, high-quality raw materials can be provided for the production of moxibustion products.

Moxa linear vibrating screen video

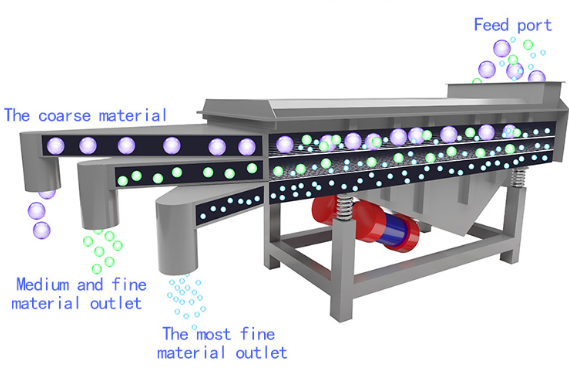

How does the moxa linear vibrating screen work

Moxa linear vibrating screen uses a vibration motor as the vibration source. When the vibration motor is running, the excitation force generated is transmitted to the screen box and the screen, causing the screen to vibrate back and forth in a straight line or approximately straight line. The moxa on the screen surface is acted upon by the excitation force and gravity, causing a jumping motion. Particles smaller than the screen hole (such as impurities and dust) pass through the screen, while moxa larger than the screen hole is retained on the screen surface, thereby achieving screening.

Advantages of moxa linear vibrating screen

1. Avoid the entanglement of moxa: Select the appropriate screen material and structure to reduce the friction between moxa fibers and the screen, and reduce the possibility of entanglement. At the same time, according to the characteristics of moxa and screening requirements, select the appropriate screen hole shape and size so that moxa can pass through the screen smoothly and reduce the accumulation and entanglement of fibers at the screen holes.

2. Achieve precise grading: Through the design of multi-layer screens, moxa can be accurately graded into different meshes according to the different needs of customers, such as 8:1, 15:1, 30:1 and other moxa products with different proportions to meet the needs of different fields such as moxibustion and moxa stick production.

3. Reduce loss: The moxa linear vibrating screen adopts a gentle vibration method to reduce the friction and collision of moxa during the screening process and reduce loss. The equipment is reasonably designed, easy to operate and maintain, and reduces the loss of moxa due to equipment failure.

4. Reduce labor intensity: Reduce physical labor in the manual screening process. The operator only needs to feed the moxa into the vibrating screen, and the equipment can automatically complete the screening process, reducing the labor intensity of workers and improving work safety.

Application of moxa linear vibrating screen

In the moxibustion production line, the moxa linear vibrating screen is usually located in the raw material pretreatment link, which is used for the initial screening and grading of the moxa raw materials. The screened moxa has higher purity and uniformity, which is more conducive to subsequent processing and molding.

1. Primary processing of moxa: Preliminary screening of moxa raw materials to remove larger impurities and wood fibers.

2. Moxa grading: The screened moxa is graded according to different particle sizes to meet the needs of different moxibustion products.

3. Preparation of moxa powder: Process moxa into powders of different fineness for making moxibustion strips, moxibustion balls and other products.

4. Preparation of moxa fillers: Remove impurities in moxa fillers to ensure the purity of the fillers.

How do you maintain a moxa linear vibrating screen?

Equipment cleaning: After each use, the moxa residue on the surface and inside of the equipment should be cleaned in time to prevent the accumulation of moxa from affecting the operation of the equipment, especially the screen part, to prevent moxa from clogging the screen holes. Compressed air or a soft brush can be used for cleaning.

Operation status check: Before starting the machine, check whether the connecting bolts of the vibration motor, screen box, spring and other components are loose. If they are loose, they need to be tightened in time; during operation, pay attention to whether the equipment has abnormal noise and whether the vibration is stable. If abnormalities are found, the machine should be stopped immediately for investigation.

Moxa linear vibrating screen plays an important role in the moxibustion industry. Through screening, the purity and quality of moxa can be improved, and the quality of moxibustion products can be guaranteed. When choosing a moxa linear vibrating screen, the appropriate equipment should be selected according to the characteristics of moxa and production requirements.

-

Screening and filtering of particles, powders, liquids and other materials

-

Filter wheat flour and remove unwanted particles to ensure product quality

-

Carbon material vibrating screen

Carbon material vibrating screen is a device specially used for screening carbon materials. Carbon...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

River sand linear vibrating screen

River sand linear vibrating screen is a commonly used screening equipment, which is used to...

-

Titanium powder vibrating screen

Titanium powder vibrating screen is a device specially used for screening titanium powder. It is...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.