Mushroom vibrating screen

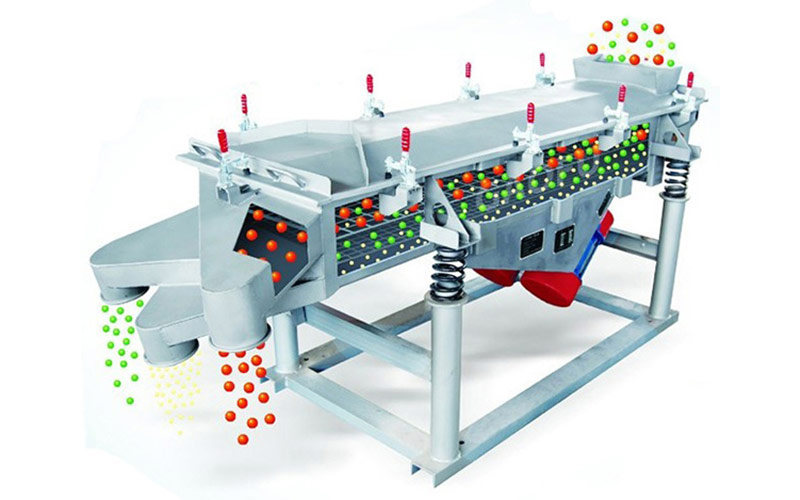

Mushroom vibrating screen is a piece of equipment specially used for screening, grading and cleaning during mushroom processing. It effectively separates and grades mushrooms based on their size, shape integrity, quality differences and other factors, and at the same time removes impurities entrained during the mushroom growth process, thereby improving the quality and consistency of mushroom products and meeting the needs of different mushroom processing and sales links.

Working principle of Mushroom vibrating screen

The mushrooms to be separated are fed through the hopper, and the screen starts to vibrate. The mushrooms fed into the hopper will pass through the screen according to their size. The mushrooms that are larger than the screen holes remain on the screen surface, and the mushrooms that are smaller than the screen holes will remain on the screen surface. Particles pass through the sieve holes.

Recommended mesh size of Mushroom vibrating screen

1.Coarse screening: If the purpose is to remove large impurities in mushrooms or conduct rough classification, you can choose a 30-mesh or 60-mesh screen. The pore size of the 30-mesh screen is about 0.59 mm, which is suitable for screening out larger impurities; the pore size of the 60-mesh screen is about 0.25 mm, which can further refine the classification.

2.Medium screen: For mushrooms that require medium grading, you can choose an 80-mesh or 100-mesh screen. The 80-mesh screen has a pore size of approximately 0.18 mm, which is suitable for grading most medium-sized mushrooms; the 100-mesh screen has a smaller pore size and can further refine the classification.

3.Fine screening: If you need to perform very fine classification or remove tiny impurities, you can choose a 120-mesh or 140-mesh screen. The pore sizes of these screens are very small, which ensures that the mushrooms screened out are very uniform in size.

Advantages of Mushroom vibrating screen

Efficient impurity removal: By setting up screens with different mesh sizes, soil, impurities and mycelium on the mushroom surface can be effectively removed. The high-frequency vibration makes the mushrooms jump continuously on the screen surface and fully contact with the screen mesh, thereby achieving better screening effect.

Protect mushrooms: Use reasonable vibration frequency and amplitude to avoid excessive damage to mushrooms. The screen and screen box are made of stainless steel to reduce friction and scratches on the mushrooms.

Graded discharge: The multi-layer screen structure not only helps reduce mushroom damage, but also achieves more uniform screening. After each layer of screen is screened, a corresponding outlet is set to discharge the screened mushrooms in a timely manner to avoid excessive mixing of mushrooms of different sizes on the screen. This allows the mushrooms to be gradually separated according to their size, improving the uniformity and accuracy of screening.

Application fields of mushroom vibrating screen

1. Mushroom planting base: After mushroom picking, the mushrooms need to be initially screened to remove impurities such as soil, residual leaves, undersized or deformed mushrooms. The mushroom vibrating screen can complete this work quickly and efficiently, improving the purity of the mushrooms and preparing them for subsequent processing or sales.

2. Mushroom processing enterprises: Different grades of mushrooms can be used for different processed products. For example, larger and complete mushrooms can be used to make canned mushrooms, medium-sized mushrooms can be used to make dried mushrooms, and smaller mushrooms can be used. For making mushroom sauce, etc., this can make full use of mushroom resources and improve the quality and added value of the product.

3. Mushroom sales market: Mushrooms that have been screened and graded have a neat appearance and uniform size, and are also easy to price and sell.

To sum up, mushroom vibrating screen is an efficient and accurate screening equipment with broad application prospects in many industries such as food. When selecting and purchasing, comprehensive considerations need to be made based on actual production needs and material characteristics.

-

Screening and filtering of particles, powders, liquids and other materials

-

Filter wheat flour and remove unwanted particles to ensure product quality

-

Wheat flour vibrating screen

Wheat flour vibrating screen is a device used for screening and classifying wheat flour particles. It usually uses vibration...

Corn starch vibrating screen

Corn starch vibrating screen is a specialized piece of equipment used for screening corn starch. It uses mechanical vibration...

Alumina vibrating screen

Alumina vibrating screen is a mechanical equipment specially used to screen alumina powder or particles. It is usually used in...

Popcorn vibrating screen

Popcorn vibrating screen is a screening equipment specially designed for the popcorn processing industry. It uses...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.