Nano Alumina for Powder Sieving Machine

Nano alumina is a nanomaterial with broad application prospects and excellent physical and chemical properties, so its screening process has certain particularities. Therefore, in the production and processing of nano aluminum, powder sieving machine plays a key role. The nano alumina sifting machine sieves and grades nano alumina powder through the action of vibration and screen to obtain the required particle size distribution and purity. powder sieving machine

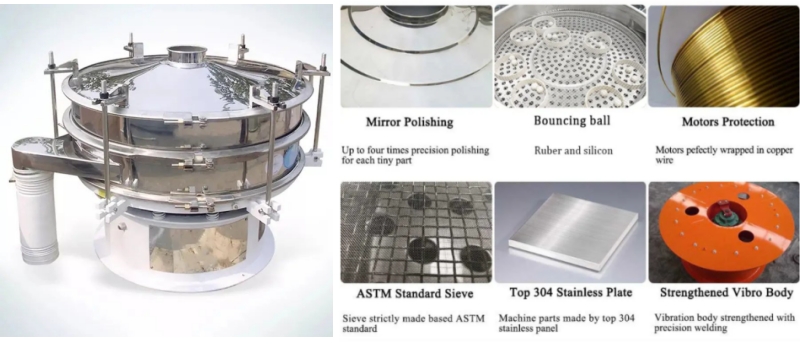

First of all, the nano aluminum for powder sieving machine adopts a special screen and paddle structure to adapt to the special properties of nano-scale powder. The screen is usually made of high-precision stainless steel wire mesh or special materials with fine pore size and good wear resistance to ensure the screening accuracy and screening efficiency of nano aluminum powder. The paddle structure is reasonably designed and the rotation speed is adjustable to generate appropriate shear force and fluidity to ensure uniform distribution and flow of nano-alumina powder on the screen.

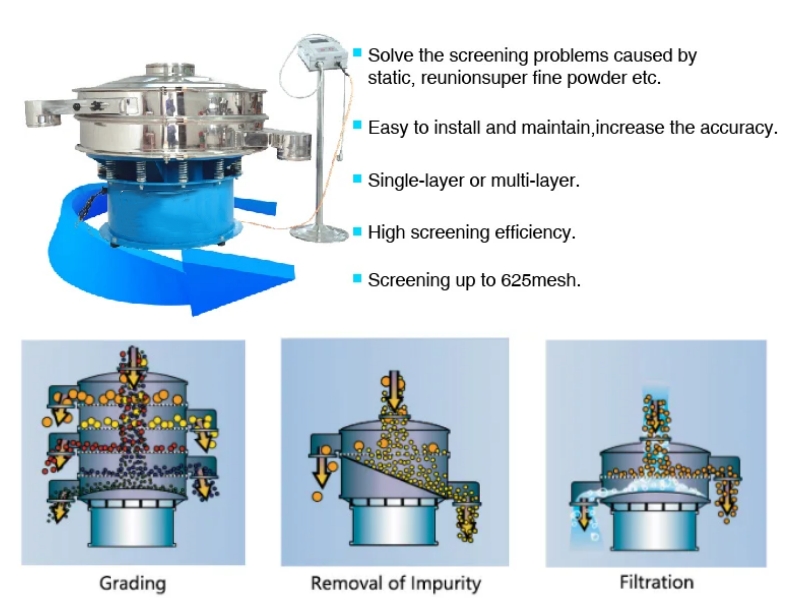

Secondly, nano aluminum for powder sieving machine adopts precise mixing mode and control system to achieve precise screening and classification. The stirring mode can be adjusted according to the characteristics of nano-alumina powder and product requirements, including radial flow, cross flow and radial-cross flow modes. By adjusting parameters such as stirring speed, amplitude and stirring time, the particle size distribution and purity of nano aluminum powder can be controlled to meet the needs of different applications. At the same time, the powder screening machine is equipped with an advanced automated control system that can monitor and adjust the screening process in real time to improve the stability and consistency of production.

In addition, nano aluminum for powder sieving machine also takes into account the special properties and process requirements of nano aluminum powder. Nano-alumina powder has a large specific surface area and high surface energy, and is easy to aggregate and agglomerate. In order to avoid powder aggregation and agglomeration, powder screening machines usually adopt anti-stick coating and anti-static measures to reduce the adhesion and adhesion of powder to the screen. In addition, the sealing performance and cleanliness of the powder screening machine have also been paid attention to to avoid the entry of impurities and pollutants and ensure the purity and quality of nano-alumina powder.

In short, nano alumina for powder sieving machine plays a vital role in the production and processing of nano alumina. It achieves control of the particle size distribution and purity of nano-alumina powder through a special screen and paddle structure, precise stirring mode and control system. The application of nano alumina for powder sieving machine promotes the research and development of nano alumina materials and promotes the progress and application of nanotechnology. With the continuous development of science and technology, the design and optimization of nano aluminum for powder sieving machine will be further improved to meet the growing market demand.

-

Removes all oversized contamination or agglomerates from powder ...

-

metal powder sieving machine price

After choosing the model of the metal powder sieving machine for the customer, its price becom ...

-

Diatomaceous Earth for Powder Sieving Machine

The application of Powder Sieving Machine in the field of Titanium Dioxide has the advantages of efficient screening. ...

-

Diatomaceous Earth for Powder Sieving Machine

The application of Powder Sieving Machine in the field of Diatomaceous Earth has the advantages of efficient screening...

-

Bentonite for Powder Sieving Machine

The application of powder sieving machine in the field of bentonite has the advantages of efficient screening....

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.