Nano Carbon Black for Powder Sieving Machine

The powder sieving machine plays an important role in the production and processing of nano carbon black powder. It controls the particle size distribution and purity of nano carbon black powder through screening technology. Nanocarbon black is a nanomaterial with broad application prospects and excellent physical and chemical properties, so its screening process has certain particularities.

First of all, nano carbon black for powder sieving machine needs to consider its special particle size characteristics. The particle size of nano carbon black powder is usually at the nanometer level, with a large specific surface area and high surface energy. Due to this particularity, nanocarbon black powder is prone to aggregation and agglomeration, resulting in enhanced binding force between powder particles. Therefore, measures need to be taken during the screening process to prevent powder agglomeration and ensure the dispersion and fluidity of the powder. Commonly used methods include adding dispersants, using special screen materials and structures, and reasonably controlling screening parameters.

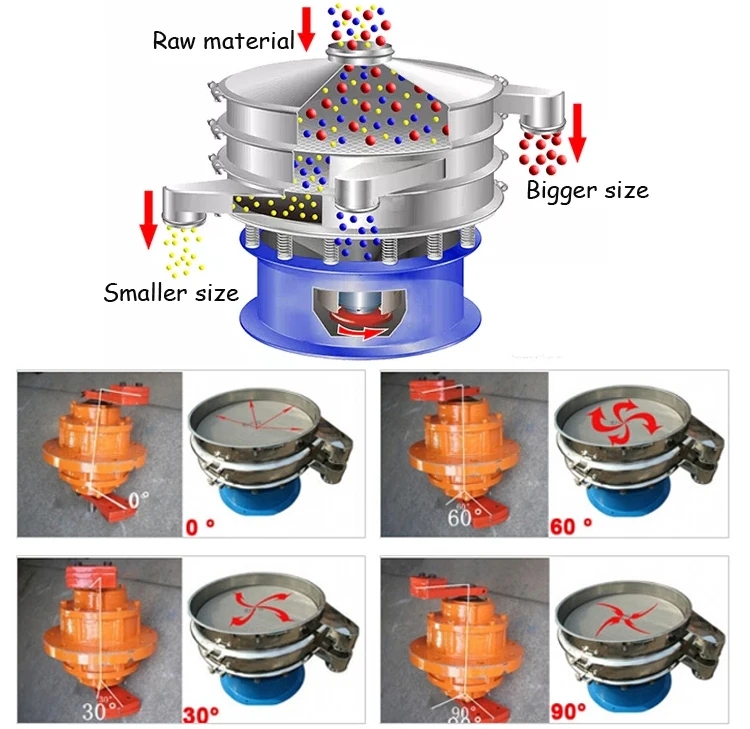

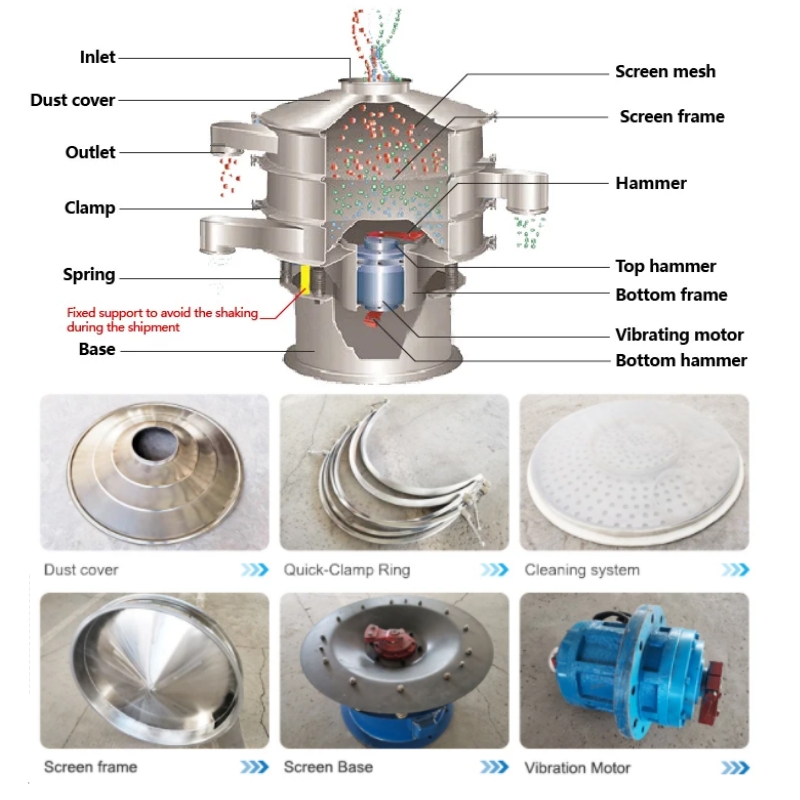

Secondly, nano carbon black for powder sieving machine needs to ensure screening accuracy and screening efficiency. Due to the small particle size of nano carbon black powder, traditional screens may not be able to meet the requirements. Therefore, screening machines usually use high-precision stainless steel wire mesh or screens made of special materials, which have small apertures and good wear resistance. This kind of screen can effectively control the particle size distribution of nano carbon black powder and achieve the required screening effect. At the same time, the paddle structure of the screening machine is reasonably designed and the rotation speed is adjustable to generate appropriate shear force and fluidity to ensure the uniform distribution and flow of nano carbon black powder on the screen.

In addition, nano carbon black for powder sieving machine also needs to consider its purity and impurity control. As a high-purity material, nanocarbon black has a low tolerance for impurities. Therefore, during the screening process, it is necessary to ensure that the screening machine has good sealing performance to prevent impurities and contaminants from entering. At the same time, the cleanliness of the screening machine is also very important. The screen and screening machine should be cleaned and maintained regularly to ensure the purity and quality of nano carbon black powder.

In short, powder sieving machine plays a vital role in the sieving process of nano carbon black. It achieves control of the particle size distribution and purity of nanocarbon black powder by using a special screen and paddle structure, precise stirring mode and control system.

-

Screening and filtering of particles, powders, liquids and other materials

-

Filter wheat flour and remove unwanted particles to ensure product quality

-

Diamond Vibrating Screen

Diamond vibrating screen is a device used for screening and grading diamond particles. Through vibration force and screen structure ...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials, easy agglomeration, low melting point, ...

-

Sugarcane Juice Bioethanol Vibro Sifter

Sugarcane Juice Bioethanol Vibro Sifter is a device for filtering sugarcane juice, mainly used for sugarcane juice filtration in bioethanol industry. ...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.