Overview of vibrating screen equipment (1)

There are many types of vibrating screen equipment. Different industries, different materials, and different uses require different vibrating screen equipment. Today, we mainly start with fine screening vibrating screen equipment to understand them:

In terms of shape, vibrating screen equipment can be divided into airflow screen, circular vibrating screen and linear vibrating screen

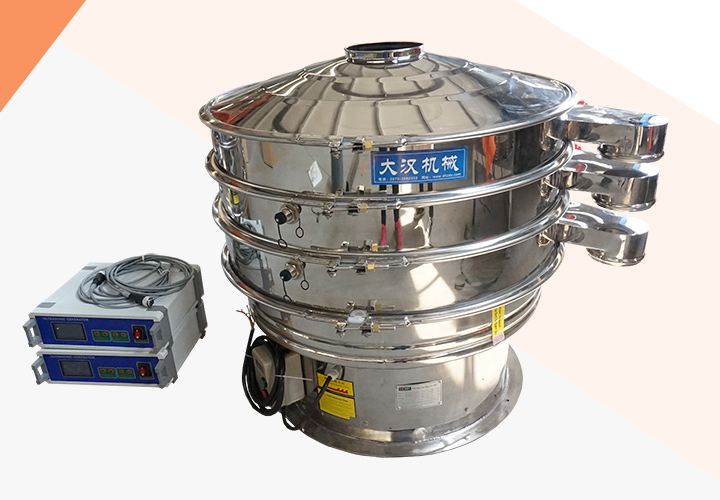

Overview (1) is an introduction to the circular vibrating screen.

Circular vibrating screen

Our common circular vibrating screen is three-dimensional vibrating screen (rotary vibrating screen) and circular vibrating screen.

The rotary vibrating screen is through the joint movement of the motor and the upper and lower eccentric weights, which can make the material move in three directions: horizontal, vertical and inclined on the screen, so it is also called a three-dimensional vibrating screen. The screening fineness is 2 mesh. -500 mesh (0.028mm)

The highest 5 layers can be screened at 6 levels, which can filter, remove impurities and classify granules, liquids and powder materials.

The three-dimensional vibrating screen is specially designed and can be listed as follows:

High-frequency vibrating screen: carry out solid-liquid separation/processing of solid and liquid mixture materials; impurity removal/removal of impurities and foreign matter. It is mostly used for screening ceramic glaze, mud and other viscous slurry materials

In-line sieve: used to remove impurities or separate materials of two different mesh numbers, mostly used at the front end of the production line to play the role of "quality inspector"

Ultrasonic vibrating screen: On the basis of the conventional rotary vibrating screen, an ultrasonic system is added, which is especially suitable for screening ultra-fine powder materials that are light and fine, and are easily sticky and electrostatically charged.

Gas protection vibrating screen: install gas protection device (can also install ultrasonic system at the same time), through inert gas to isolate lively materials from contact with air, mostly used for screening magnetic materials, 3D printing materials

Tumbler Screen

A fine screening equipment with finer and larger output than the rotary vibrating screen. The unit output area of the circular oscillating screen is 5-10 times that of ordinary screening machines, the output can reach up to 60t/h, the screening accuracy can reach 95%, and the screening fineness can reach 500 mesh or more. Fine powder materials have good screening effect.

The screening principle of the circular swing screen is also different from that of the traditional vibrating screen. It screens the material by simulating the movement of the manual use of the dustpan for screening. The vertical movement of the material is very small during screening. The screen is small and the screen is more durable. The screen of the traditional screen machine is generally replaced once a month, while the use time of the screen of the swing screen is basically more than 5 times that of the traditional screen machine, and the screen replacement time can also be completed within 3-5 minutes. .

The circular swinging screen only has three cleaning methods: roller brush, pinball and ultrasonic, which can avoid the problem of material blocking of the swinging screen to the greatest extent.

In addition, due to the gentle screening method of the circular swinging screen, it is very suitable for the screening of powders and brittle materials that are prone to static electricity, and can protect the shape of materials to the greatest extent from damage, such as chicken essence, flour, silicon powder, protein powder, citric acid , Xylitol, etc.

-

Can sieve ultra-fine powder down to 20 microns without clogging the sieve holes ...

-

Mainly used for powder, granule and liquid materials, sieving fine to 500 meshes, filtering up to 5 microns. ...

-

Potato Starch Vibrating Screen

Mainly used for powder, granule and liquid materials, sieving fine to 500 meshes, filtering up to 5 microns. ...

-

Titanium Alloy Vibrating Screen Screening Solutions

Generally, ordinary ternary vibrating screen can be used for coarse particle screening and impurity removal, ...

-

What exactly is the Teflon Vibrating Screen?

Our materials cant be in contact with other materials Our materials cant rub against the screen frame to produce fine powder during production ...

-

What is the function of ultrasonic vibrating screen?

Ultrasonic vibrating screen is an ultrasonic system added on the basis of ordinary vibrating screen. ...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.