Pharmaceutical powder vibrating screen

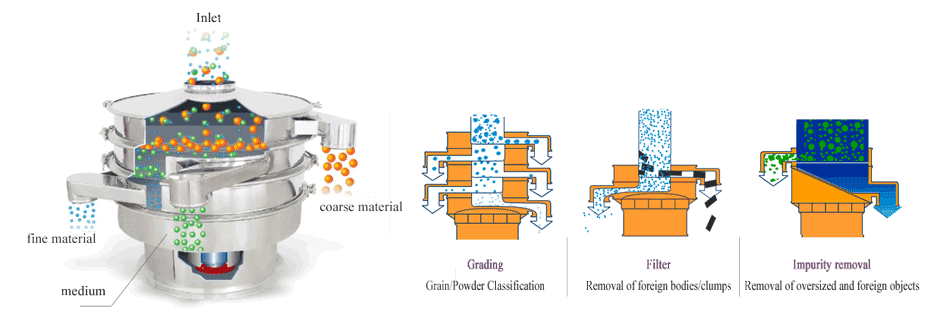

Pharmaceutical powder vibrating screen is a specialized device used for screening pharmaceutical powders. By utilizing vibration and the movement of the, it separates pharmaceutical powders according to different particle sizes. It is mainly used for screening, filtering, and grading pharmaceutical powders to achieve particle size control, separation, and impurity removal. In the pharmaceutical industry, the pharmaceutical powder vibrating screen plays a crucial role in ensuring the purity and quality of drugs, thereby safeguard patient medication safety.

Working principle of Pharmaceutical powder vibrating screen

The vibration force generated by the vibrating motor causes the screen box to vibrate. The screen undergoes periodic vibration in the horizontal direction, which in turn drives the pharmaceutical powder on the screen for screening. The pharmaceutical powder enters the device through the feed port passes through the screening layers of different mesh sizes, and finally, the pharmaceutical powders of different particle sizes are discharged from the corresponding outlets of each layer.

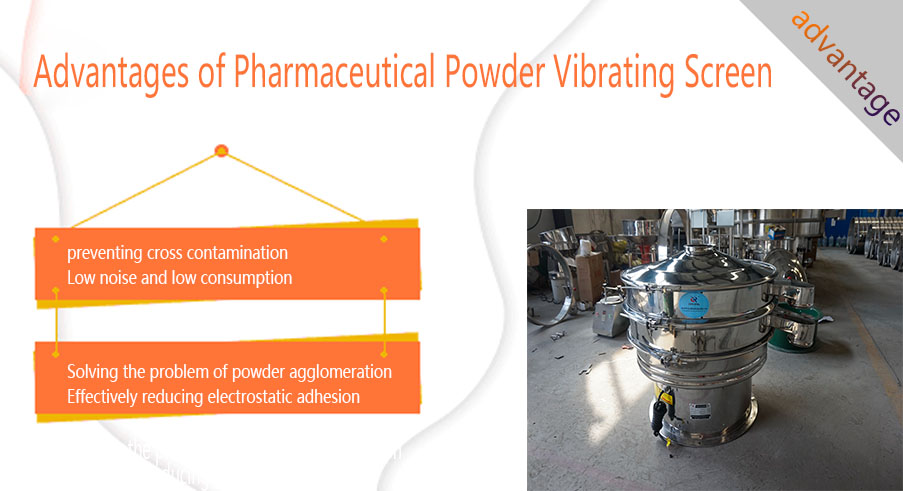

Advantages of Pharmaceutical Powder Vibrating Screen

1. Preventing cross contamination:It adopts a fully enclosed structure and stainless steel material, effectively preventing external impurities from mixing into the medicinal powder, avoiding cross-contamination between different and different types of powders, and ensuring that the purity and quality of the medicine meet the GMP requirements.

2. Low noise and low consumption: Advanced vibration technology and optimized equipment structure result in lower noise during operation, meeting the environmental requirements of pharmaceutical workshops; reasonable power configuration and high-efficiency screening make the equipment relatively low in energy consumption, reducing the operating costs of the enterprise.

3. Solving the problem of powder agglomeration: The vibrating makes the pharmaceutical powder exhibit complex motion trajectories on the screen, such as jumping, rolling, and sliding. This multi-directional vibration can effectively break up agglomer powders, allowing the powder particles to fully disperse, facilitating screening, and improving screening efficiency and accuracy.

4. Effectively reducing electrostatic adhesion: adjusting the humidity in the screening workshop, the environmental humidity is kept within an appropriate range, reducing the possibility of electrostatic adhesion due to dryness. Generally a relative humidity of 40%-60% is suitable.

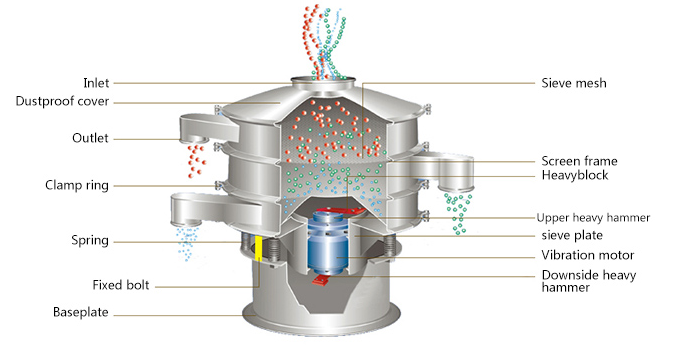

Structure of Pharmaceutical powder vibrating screen

Screen Box: screen box is the main body of the vibrating screen, usually made of stainless steel, characterized by corrosion resistance and ease of cleaning.

Screen: The screen is the component of the screening, different aperture screens can screen out pharmaceutical powder particles of different sizes. The material of the screen is usually stainless steel to ensure food hygiene.

Vibrating Motor: Provides the power for vibration, causing the screen box to vibrate.

Base Frame: Supports the entire vibrating screen, ensuring the stable operation the pharmaceutical powder vibrating screen.

Applications of Pharmaceutical Powder Vibrating Screen

1. Screening of pharmaceutical raw materials: In the of raw drugs, various chemical synthetic raw materials and natural extracts are screened to remove impurities and particles that do not meet the particle size requirements, ensuring the purity quality of the raw drugs, and providing a high-quality raw material base for subsequent drug formulation production.

2. Drug formulation production: Used in the production of various formulations such as tablets, capsules, powders, and granules, the drug powder is accurately screened to ensure the uniformity and particle size distribution of the drug meet the formulation process requirements, thereby ensuring the stability of the drug quality and the consistency of the therapeutic effect.

3. Processing of Chinese medicine powders: the field of Chinese medicine pharmaceuticals, the Chinese medicine powders that have been crushed are screened to separate powders of different coarseness, allowing for formula and preparation processing according to the principles of traditional Chinese medicine and clinical needs, improving the quality and efficacy of Chinese medicine preparations.

4. Screening of pharmaceutical intermediates Screening of pharmaceutical intermediates ensures their particle size and purity meet the requirements of the next step of synthesis reaction or processing technology, helping to improve reaction yield and product, reduce production costs and waste rate.

Pharmaceutical Powder Vibrating Screen plays an important role in the pharmaceutical manufacturing process, helping to ensure the quality and efficacy of drugs through precise screening and grading. As technology continues to develop, the application range of pharmaceutical powder vibrating screens will continue to expand.

-

Screening and filtering of particles, powders, liquids and other materials

-

Filter wheat flour and remove unwanted particles to ensure product quality

-

Corn starch vibrating screen

Corn starch vibrating screen is a specialized piece of equipment used for screening corn starch. It uses mechanical vibration...

-

Alumina vibrating screen

Alumina vibrating screen is a mechanical equipment specially used to screen alumina powder or particles. It is usually used in the production and processing of alumina powder. ...

-

Popcorn vibrating screen

Popcorn vibrating screen is a screening equipment specially designed for the popcorn processing industry. It uses high-frequency and large-amplitude vibrations...

-

Porcelain slurry vibrating screen

Porcelain slurry vibrating screen is a special equipment used to screen porcelain slurry. Porcelain slurry is an important intermediate material...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.