Plastic particle vibrating screen

Plastic particle vibrating screen is a device specially used for screening plastic particles. It is mainly used to separate, screen and classify plastic particles. Through mechanical vibration, plastic particles of different sizes are caused to move relative to each other on the screen surface, thereby achieving particle separation and screening purposes, meeting different screening requirements. This equipment is widely used in the plastic processing industry, especially in plastic recycling and plastic product production.

Video of Plastic particle vibrating screen

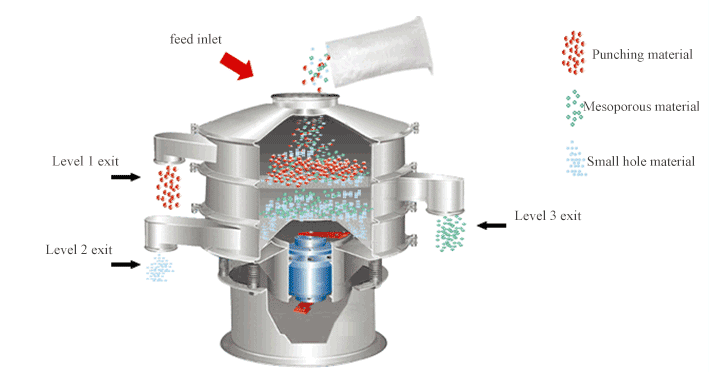

How does the plastic particle vibrating screen work?

The vibration force generated by the vibration motor causes the screen surface to resonate, thereby driving the material on the screen to jump and roll. Due to its large inertia, large particles will move forward along the screen surface and be discharged from the discharge port, while small particles will fall into the lower layer through the pores of the screen, and finally achieve the separation of materials of different particle sizes.

What are the advantages of Plastic particle vibrating screen

1. Large processing capacity of plastic particles: Its structural design is reasonable, and the screen area can be customized according to needs. It can process a large number of plastic particles at the same time to meet the needs of large-scale production.

2. Appropriate addition of dispersant: Adding an appropriate amount of dispersant to the plastic particles can reduce the surface tension and viscosity between the particles, making the particles easier to disperse, which helps to improve the screening effect.

3. Accurate vibration control: Through advanced vibration control technology, ensure that the vibration parameters of the vibrating screen are stable and accurate. Stable vibration can make the movement trajectory of plastic particles on the screen surface more regular, which is conducive to improving the screening accuracy.

4. Adapt to the particle size range of different plastic particles: The particle size range of screening can be flexibly adjusted according to production needs. From coarser particles to fine micro-powder particles, accurate screening can be achieved by selecting appropriate screens and vibration parameters.

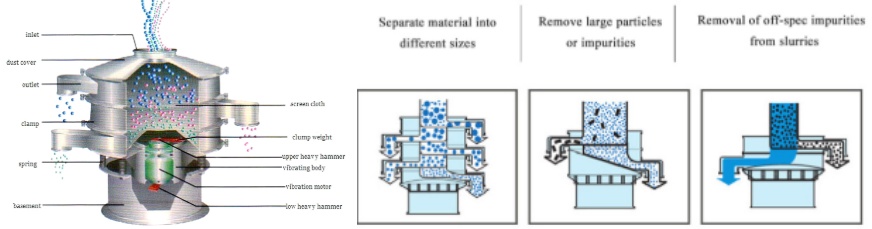

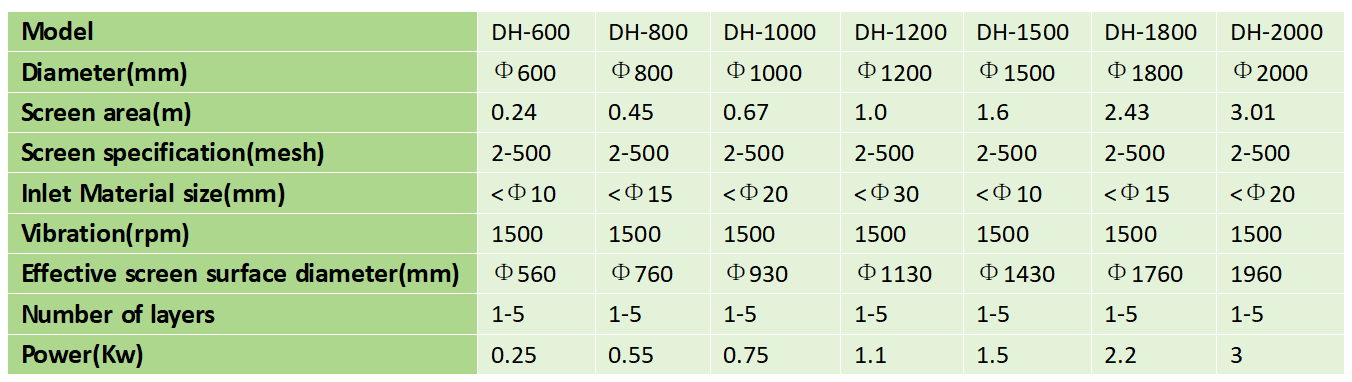

Structure and technical parameters of Plastic particle vibrating screen

Application of Plastic particle vibrating screen

1. Plastic granulation industry: Plastic particle vibrating screen is used to grade and screen newly produced plastic particles, remove particles that are too large or too small, ensure the uniformity of the particle size of plastic particles, and improve product quality.

2. Plastic recycling industry: Screen the recycled waste plastics and separate plastic particles of different particle sizes for subsequent processing.

3. Plastic processing industry: Screen the purchased plastic particle raw materials to remove impurities and particles that do not meet the particle size requirements to ensure the smooth progress of the processing process and product quality.

Common problems and solutions for Plastic particle vibrating screens

1.No material flow: Possible reasons include unbalanced screen box level, too hard or damaged support springs, wrong movement direction of vibration motor or improper amplitude setting, etc.

Solution: Adjust the level of the screen box, replace the support springs, adjust the movement direction and amplitude of the vibration motor, etc.

2.Screen blockage: Screen blockage will lead to reduced screening efficiency.

Solution: Use rubber balls to clean the screen, regularly replace worn screens, and select appropriate screen materials and aperture sizes.

3.High equipment noise: Possible reasons include unbalanced vibration motors, loose or damaged support springs, etc.

Solution: Check and adjust the balance of the vibration motor, replace damaged support springs, etc.

Plastic particle vibrating screen customer case

Plastic particle vibrating screen supplier

-

Screening and filtering of particles, powders, liquids and other materials

-

Filter wheat flour and remove unwanted particles to ensure product quality

-

Airflow sieve for Chinese medicine powder

Airflow sieve for Chinese medicine powder plays a vital role in the Chinese medicine pharmaceutical...

-

Bread Flour Vibrating Screen

Bread flour vibrating screen is a special equipment for screening bread flour. In the production process...

-

Paint vibrating screen

Corn starch vibrating screen is a specialized piece of equipment used for screening corn starch. It uses...

-

Popcorn vibrating screen

Popcorn vibrating screen is a screening equipment specially designed for the popcorn processing industry. It...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.