Plastic sheet vibrating screen

Plastic sheet vibrating screen is a kind of equipment specially used for screening plastic particles or granular plastic raw materials. It is widely used in plastic recycling, granulation, injection molding and other industries. It uses the exciting force generated by the vibration motor to make the plastic sheets move on the screen surface, so as to achieve the purpose of screening, grading or removing impurities of plastic sheets of different sizes. Plastic sheets of different sizes are separated. In the plastic processing industry, plastic sheet vibrating screen plays a vital role. It can effectively remove impurities and ensure product quality and production efficiency.

Video of plastic sheet vibrating screen

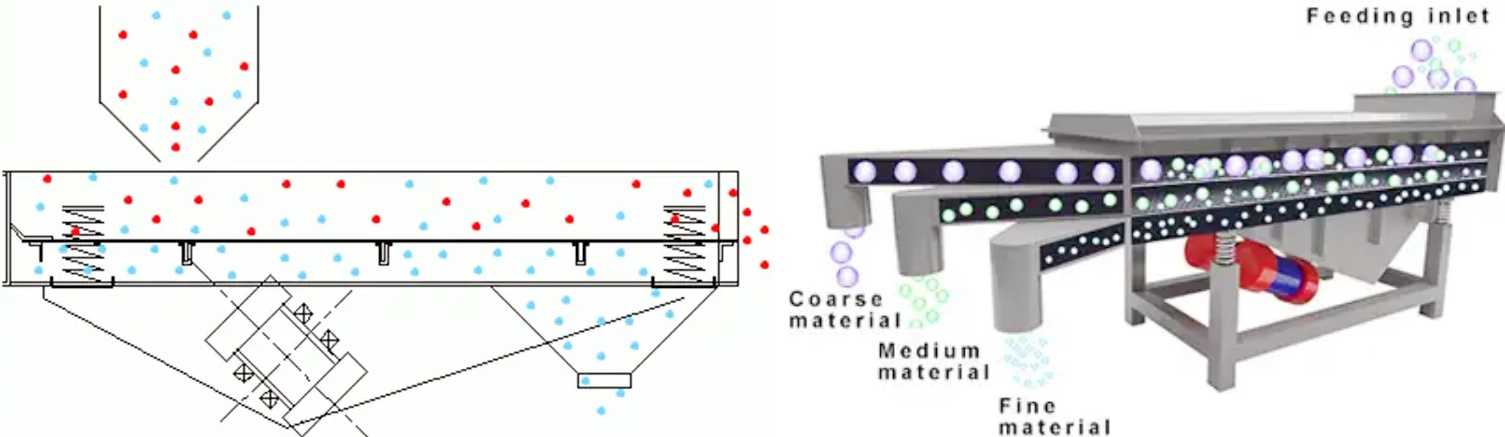

How do plastic sheet vibrating screens work?

1. Vibration source: The vibration motor generates excitation force to drive the screen box and screen mesh to vibrate.

2. Screening process: The plastic sheets are vibrated on the screen surface, smaller particles pass through the screen holes, and larger particles remain on the screen surface to achieve classification.

3. Discharge method: The screened plastic sheets are discharged from different discharge ports to complete the screening process.

Features of plastic sheet vibrating screen

Suitable for plastic particle screening: The plastic sheet vibrating screen is designed to screen plastic particles or granular plastic raw materials, which helps to remove impurities and particles of different sizes.

Efficient screening: Through vibration movement, the plastic sheet vibrating screen can quickly separate and screen plastic particles to improve production efficiency.

Accurate classification: The plastic sheet vibrating screen can accurately classify plastic particles as needed to ensure that the product meets specific specifications.

Customized options: Some manufacturers provide customized plastic sheet vibrating screens to meet customers' specific screening needs and production requirements.

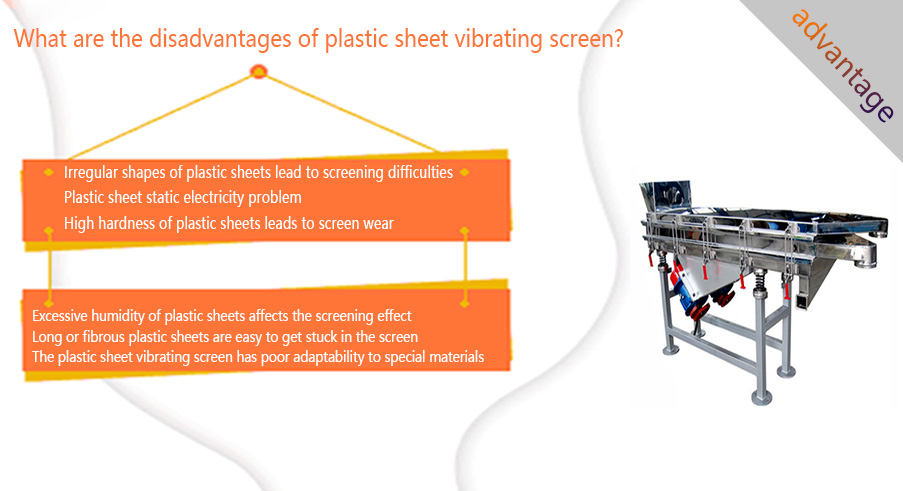

What are the disadvantages of plastic sheet vibrating screen?

1. Irregular shapes of plastic sheets lead to screening difficulties: Plastic sheets come in a variety of shapes (such as sheets, granules, strips, etc.), which are easily stuck in the sieve holes, causing the screen to be blocked.

2. Plastic sheet static electricity problem: Plastic sheets are prone to static electricity during the screening process, causing the material to adhere to the screen or the inner wall of the equipment, affecting the screening efficiency.

3. High hardness of plastic sheets leads to screen wear: Hard plastic sheets rub against the screen during the screening process, which can easily cause the screen to wear and shorten its service life.

4. Excessive humidity of plastic sheets affects the screening effect: When the humidity of plastic sheets is too high, they are easy to stick together, resulting in uneven screening or clogging of the screen holes. Dry the plastic sheets before screening. Choose screening equipment suitable for wet materials.

5. Long or fibrous plastic sheets are easy to get stuck in the screen: Long or fibrous plastic sheets are easy to get stuck in the screen holes, affecting the screening effect and equipment operation.

6. The plastic sheet vibrating screen has poor adaptability to special materials: For some special plastic sheets, the vibrating screen has poor adaptability.

Structure of Plastic Sheet Vibrating Screen

The plastic sheet vibrating screen has a simple structural design and clear functions. It is mainly composed of screen box, screen mesh, vibration motor, support spring, base and other components. Through reasonable configuration and optimized design, the screening task of plastic sheets can be completed efficiently.

Application of Plastic Sheet Vibrating Screen

1. Screening of plastic raw materials: In the first step of plastic processing, it is usually necessary to screen the plastic raw materials to remove impurities such as metal sheets and wood chips. This helps to ensure the smooth progress of subsequent processing and improve product quality.

2. Screening of recycled plastics: After the recycled waste plastics are crushed, they are screened through a vibrating screen to remove impurities such as oversized plastic blocks and metal sheets to prepare for subsequent melting processing. The crushed plastic particles are screened to obtain particles of different particle sizes to meet the needs of different products.

3. Screening of finished plastic products: After the plastic products are formed, the burrs, flashes and other impurities on the surface of the products are removed through a vibrating screen to improve the appearance quality of the products. Plastic products of different specifications are graded to facilitate subsequent packaging and sorting.

4. Screening of plastic powder: In the production process of plastic powder, the vibrating screen can be used to remove oversized particles or impurities to ensure the uniformity of the powder.

How to fix a plastic sheet vibrating screen?

First, the vibrating screen needs to be inspected and fault diagnosed. Before repairing, the vibrating screen needs to be shut down and the power supply needs to be disconnected. If the screen is damaged or other parts are damaged, they need to be replaced in time. For parts that need lubrication, lubrication should be performed according to the requirements of the equipment manual. After the repair is completed, the parameters of the vibrating screen may need to be readjusted to ensure the normal operation of the equipment.

Plastic sheet vibrating screen plays an important role in the plastic processing industry. Through screening, the quality of the product can be improved and the production cost can be reduced. When choosing a plastic sheet vibrating screen, the appropriate model should be selected according to the specific production needs.

-

High-precision screening of materials is achieved through a unique screening method

-

Filter flour and remove unwanted particles to ensure product quality

-

Soy product vibrating screen

Detergent vibrating screen is a screening device commonly used in washing powder production...

-

Moxa linear vibrating screen

Concrete vibrating screen is a screening equipment used in concrete production. It is mainly used to screen, grade and remove impurities from ...

-

Steel fiber vibrating screen

Steel fiber vibrating screen is a kind of vibrating screening equipment specially used for...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.