Powder Sifter Machine

Callback

| Mesh size: | 2-500 mesh (20 microns) |

| Capacity: | 100-3300kg/h |

| Number of layers: | 1-5 layers |

Fully enclosed unit prevents dust and fume leakages

Quick disassembly without any tools and easy to clean

It can be used directly with vacuum feeder/dust-free feeding station to realize negative pressure and dust-free operation

Introduction of powder sifter machine

Powder sifter machine is designed for high volume sifting of powders to remove oversized contamination or agglomerates, as a way to protect ingredients and final products from contamination, due to its compact design, this sifter machine can be easily installed in In a small space, it can be easily integrated into your powder production line, the more common applications are the production lines of flour, washing powder, rice flour, graphite powder, metal powder, etc., and different sizes from 600mm to 1200mm diameter are available to meet the your production requirements.

Application of powder sifter machine

PThe powder sifter machine is used in various fields, and is widely used in the removal and classification of flour, chemical powder, pharmaceutical powder, coating powder, resin powder, metallurgical powder, electromagnetic powder, grinding powder and other processes.

1. Removing impurities: It can remove pollutants in small batches of powder. It improves the quality of your final product and protects your reputation.

2. Classification: According to the particle size, various powders can be divided into five grades: coarse powder, medium powder, fine powder, fine powder and ultrafine powder. Generally, 80 mesh, 120 mesh and 200 mesh are used to filter, and the particle size is 150- The powder composed of particles within the scale of 500μm is coarse powder, the particle size of 44-150μm is medium powder, the particle size of 10-44μm is fine powder, the particle size of 0.5-10μm is very fine powder, and the particle size of less than 0.5μm is superfine powder. Generally, the powder that can pass through the 325-mesh standard sieve, that is, the particle size is less than 44 μm, is called sub-sieve powder.

Common types of powder sifter machines

-

Industrial Sifter Machine

Mesh: 500 mesh (20 microns)

Capacity: 100-3300kg/h

Applications: Removal of oversized contaminants to preserve powder quality, compact form requires minimal headroom, can be easily integrated into your existing production line.

-

Ultrasonic vibrating screen

Mesh:: 80-600 mesh

Capacity: 100-5000kg/h

Applications: Prevents blinding and blocking when screening difficult powders, which can be screened on finer meshes (down to 20 microns).

-

Inline vibrating sieve

Mesh: 140 mesh

Capacity: 3-30t/h

Applications: For inspection screening and removal of contaminants from raw materials that are bagged into factories, and for screening powders prior to blenders or mixers.

Featured videos

-

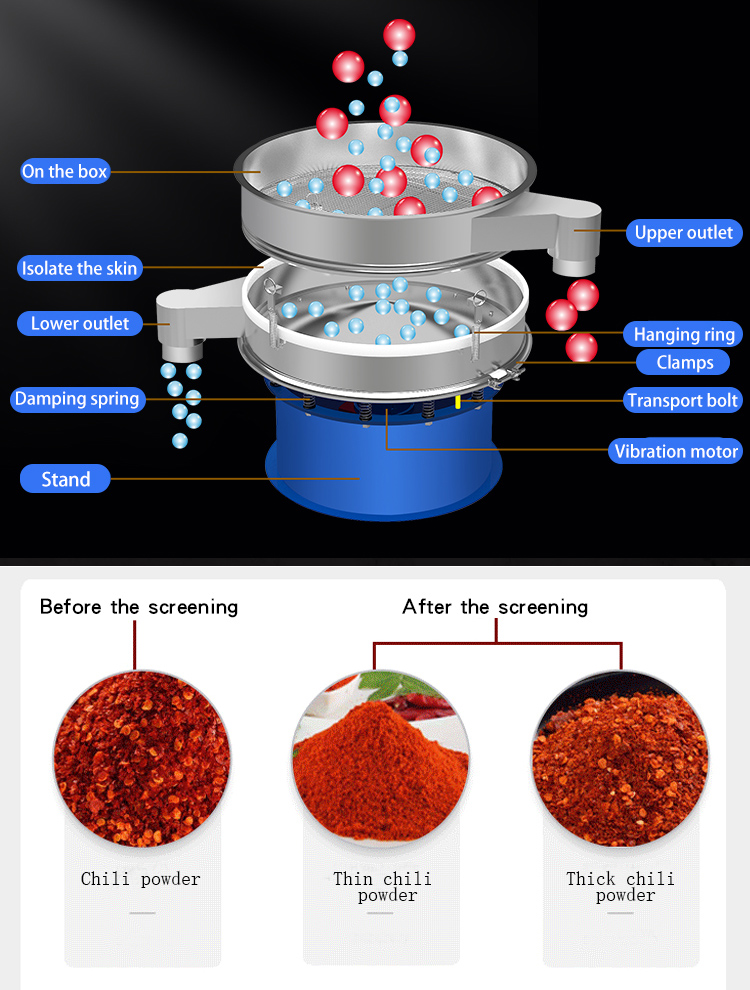

Sieving spices

-

Sieving graphite powder

Benefits of powder sifter machine

1. SUS304 or 316L stainless steel is selected, mirror polished, and the internal and external surface finish is 0.1-0.2RA, aiming to meet the strict engineering and safety standards required by the powder industry.

2. The product is poured into the sifter machine, before the powder passes through the sieve to the rest of the production line, impurities and oversized pollutants are removed to ensure the safety, hygiene and quality of the final product.

3. The fully enclosed structure avoids flying powder, eliminates the problem of dust in the air, and manual interaction is pollution-free.

4. The machine can be quickly disassembled without any tools and is easy to clean, thus increasing productivity and avoiding any chance of cross-contamination between batches.

5. Compact size meets industrial and commercial needs with minimal headroom and floor space, and fits comfortably on any production line.

Related cases

| Material | Proportion | Mesh | Processing method | Capacity (kg/hr IT/hr) |

Model |

| Wheat flour | 1 | 250 | Wet | 3200 IT | DH-1200-1S |

| Flour | 0.6 | 24 | Dry | 1500㎏ | DH-1000-1S |

| Rice flour | 0.5 0.8 | 100 | 300 ㎏ | DH-1000-1S | |

| Pollen | 0.4 | 12 | 100㎏ | DH-1500-1S | |

| Skimmed milk powder | 0.57-0.7 | 24 | 3000㎏ | DH-1200-1S | |

| Whole milk powder | 0.57-0.8 | 12 | 1600㎏ | DH-1000-1S | |

| Sugar powder | 0.5-0.8 | 100 | 200㎏ | DH-800-1S | |

| Corn starch | 0.6 | 40 | 1600㎏ | DH-1000-1S | |

| Medicine powder | 0.8 | 80 | 550㎏ | DH-800-1S | |

| Polyethylene powder | 0.45 | 48/100 | 100㎏ | DH-800-2S | |

| Lead powder | 11.34 | 10/80 | 1000㎏ | DH-1000-2S | |

| Copper powder | 2 | 100 | 70㎏ | DH-800-1S | |

| Iron powder | 3 | 400 | 230㎏ | DH-800-1S | |

| Aluminum powder | 0.9/1.2 | 80/120 | 350㎏ | DH-800-2S |

Technical parameters

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

How to choose powder sifter machine

Powder sifter machine If you want to sieve without blocking the screen mesh, you must first understand: 1. The purpose of use is for grading or removing impurities; 2. The nature of the material and the size and output that need to be sieved; 3. There is also the material; 4. , Whether it is flammable or explosive. Understanding these four points makes it easy to choose a suitable powder vibrating sieve. How to determine it?

1. The Powder sifter machine can do 1-3 layers of sub-machine processing, and you can choose a suitable mesh screen according to your needs. Only one layer of sieve is needed to remove impurities. Generally, there are not many impurities. It can be easily sieved by selecting a pore size that is smaller than the particle size of the impurities and larger than the particle size of the material.

2. Whether the powder is sieved or impurity is removed, it is mainly realized through the sieve, so the sieve aperture must be determined well. The powder that is too fine, easy to stick, and charged with static electricity needs to use an ultrasonic vibrating sieve. If the mesh number is large, the output will also be large. Sieving can also be performed using an Inline vibrating sieve.

3. Powder sifter machine mainly has three materials: carbon steel, stainless steel, and plastic. Generally, most of the parts in contact with materials are stainless steel. There is no special requirement for carbon steel materials. Plastic materials are only suitable for severely corrosive powder materials, such as chemical powders.

4. For flammable and explosive powder sifter machine manufacturers, the vibration motor will be replaced with an explosion-proof motor to prevent accidental damage caused by motor heating.

-

Innovative high-enclosed sieving machine can accurately ...

-

The screen is fine to 500 meshes, and it is not easy to be blocked ...

-

Remove small stones, sand or clay particles, leaves, dust and other unwanted contaminants in chili powder...

-

Quartz Powder sifter machine manufacturer

Quartz sieving machine has a complete range of screens

-

Different types of powder sieve machine

The powder sieve machine can be used for the screening of various powder materials.

-

Powder Sieving Machine for epoxy

Resin refers to a general term for a class of polymers containing

-

Where is the powder sieve purchased?

Dahan powder sieve can screen 500 mesh or 0.028mm dust and granular materials

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.