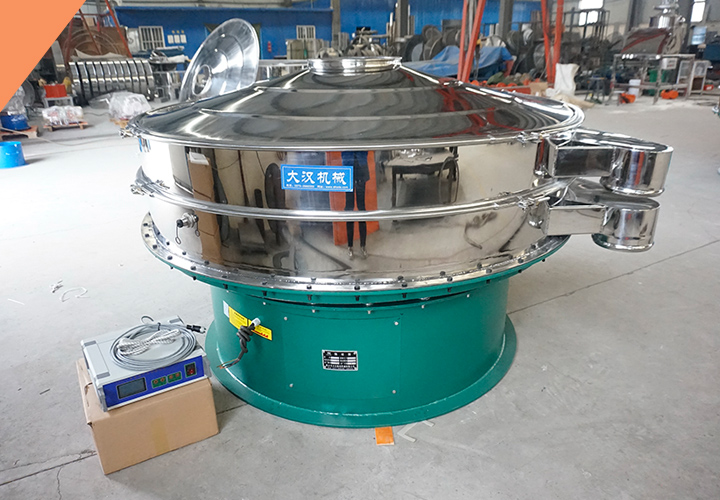

Powder Sieve Machine

![[field:title/]](/uploads/211119/1-21111915201L61.jpg)

Callback

| Mesh size: | 2-500 mesh |

| Capacity | 100-3300kg/h |

Multi-layer sieves classify the powder according to its particle sizeAutomatic nesting

Fully enclosed structure to reduce dust pollution

What is a Powder Sieve Machine?

Powder sieve machine, also known as a powder sifter or powder screening machine, is a device used to separate and classify fine powder particles based on their size. It is commonly used in industries such as pharmaceuticals, chemicals, food processing, and cosmetics. The main purpose of a powder sieve machine is to ensure product quality by removing impurities, lumps, and oversized particles from powdered materials.

Powder sieve machine can be widely used in pharmaceutical, chemical, food processing, mining, metallurgy and other industries. It can be used for powder screening, classification, impurity removal, powder recovery and other processes to meet the needs of different industries for powder screening.

Types of Powder Sieve Machine

There are several types of powder sieve machines available, each designed for specific applications and requirements. Here are some common types:

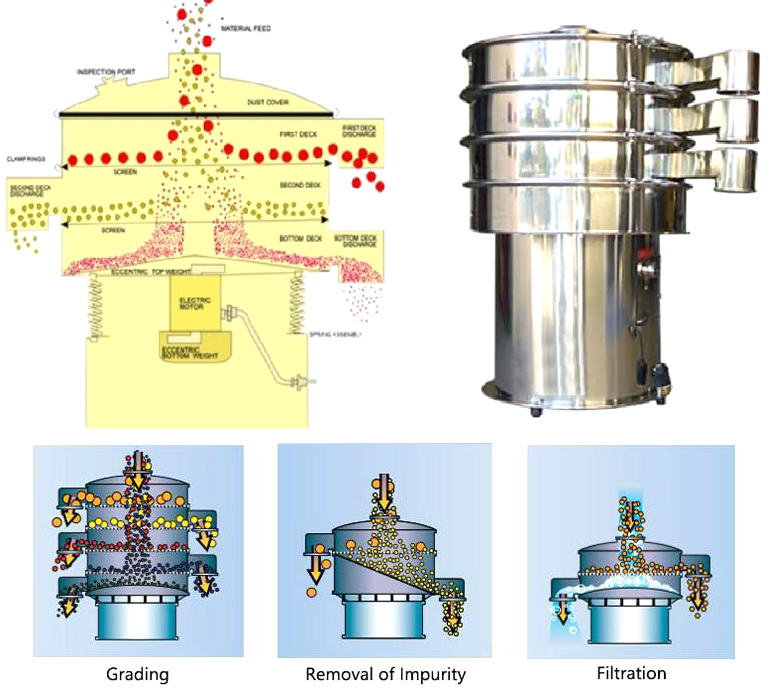

1.Vibrating Sieve Machine: This is the most common type of powder sieve machine. It uses vibration to separate and classify particles based on size. Vibrating sieve machines can have single or multiple decks with different mesh sizes for efficient particle separation.

2.Ultrasonic Sieve Machine: Ultrasonic sieve machines incorporate ultrasonic vibrations along with the standard vibration mechanism. The ultrasonic waves enhance the sieving process by improving the throughput and preventing clogging of the mesh. This type of sieve machine is particularly useful for fine powders and difficult-to-screen materials.

3.Centrifugal Sifter: A centrifugal sifter, also known as a centrifugal sieve or rotary sifter, uses centrifugal force to separate particles. The powder is fed into a cylindrical chamber that rotates rapidly, causing the particles to move towards the outer edges while the smaller particles pass through the screen.

What is the use of Powder Sieve Machine?

Powder sieve machines have several functions and play a crucial role in various industries. Here are the main functions of a powder sieve machine:

1.Particle Size Classification: The primary function of a powder sieve machine is to separate and classify particles based on their size. It helps ensure that the powdered material meets specific particle size requirements and achieves the desired particle size distribution.

2.Impurity Removal: Powder sieve machines are used to remove impurities, such as foreign particles, lumps, and agglomerates, from the powdered material. This helps improve the quality and purity of the final product.

3.Quality Control: Powder sieve machines are essential in quality control processes. They help ensure that the powdered material meets the required standards and specifications by removing oversized or undersized particles, ensuring consistency and uniformity in the final product.

4.Powder Recovery: In recycling or reusing processes, powder sieve machines recover fine particles that can be reused or recycled. They separate the fine particles from larger particles or agglomerates, maximizing the utilization of the powdered material.

Working principle of powder sieve machine

Powder sieve machine converts 220V, 50Hz or 110V, 60Hz electric energy into 18KHz high-frequency electric energy, and inputs the ultrasonic transducer to turn it into 18KHz mechanical vibration, so that the material can be up and down, horizontal and inclined on the screen surface. The moving force is also affected by the high-frequency and low-amplitude force exerted on the screen surface by the ultrasonic system, so as to achieve the purpose of screening and cleaning.

Benefits of powder sieve machine

1. Sieving to 500 meshes, no mesh blockage.

2. The vibration frequency can reach 360,000 times/min, which can completely solve the screening problems of strong adsorption, easy agglomeration, high static electricity, high precision, high density, and light specific gravity.

3. Compared with sieve machine, the screening accuracy can be increased by 1-70%, and the output can be increased by 0.5-10 times.

4. The screen can be automatically cleaned to ensure that the material is not polluted.

5. 1-5 layers of screens can be installed, and 2-6 different levels of classification tasks can be completed at the same time.

Featured videos

Technical parameters of powder sieve machine

| Model | Effective screening diameter | Screen mesh size range | No of layers | Power |

| DHC-400 | 340 | 80-600MESH | 1-3 LAYERS | 0.18KW |

| DHC-600 | 540 | 80-600MESH | 1-3 LAYERS | 0.25KW |

| DHC-800 | 730 | 80-600MESH | 1-3 LAYERS | 0.55KW |

| DHC-1000 | 900 | 80-600MESH | 1-3 LAYERS | 0.75KW |

| DHC-1200 | 1100 | 80-600MESH | 1-3 LAYERS | 1.1KW |

| DHC-1500 | 1400 | 80-600MESH | 1-3 LAYERS | 1.5KW |

| DHC-1800 | 1700 | 80-600MESH | 1-3 LAYERS | 2.2KW |

Applications of powder sieve machine

| Raw material | Proportion | Mesh size | Model | Method | Throughput (kg/hr) |

| Glucose powder | 0.8 | 6,20 mesh | DH-1200-2S | Dry | 2000㎏ |

| Wheat starch | 1 | 250 mesh | DH-1200-1S | Wet | 3200kg |

| Flour | 0.6 | 24 mesh | DH-1000-1S | Dry | 1500㎏ |

| Rice flour | 0.5 0.8 | 100 mesh | DH-1000-1S | Dry | 300 ㎏ |

| Pollen | 0.4 | 12 mesh | DH-1500-1S | Dry | 100㎏ |

| Tungsten carbide powder | 7.5-9.0 | 20-60 mesh | DH-800-2S | Dry | 400㎏ |

| Aluminum powder | 0.9/1.2 | 80,120 | DH-800-2S | Dry | 350㎏ |

Food Industry: Powder sieve machines are commonly used in the food industry for sifting flour, sugar, spices, and other powdered ingredients to ensure uniformity and remove impurities.

Pharmaceutical Industry: In the pharmaceutical industry, powder sieve machines are used to screen pharmaceutical powders to meet stringent quality control standards.

Chemical Industry: These machines are utilized in the chemical industry for sieving various chemical powders and ensuring product purity.

Cosmetics Industry: Powder sieve machines play a vital role in the cosmetics industry for sifting and classifying cosmetic powders used in the production of makeup and skincare products.

Different types of powder how to choose Powder Sieve Machine?

1. Food/medicine powder

For food powder, please choose Powder Sieve Machine made of 304 or 316L stainless steel, because stainless steel that meets hygienic standards and will not rust is the first choice for food/medicine processing machinery. For example your powder is milk powder, flour, API and others.

2. Ordinary powder

Choose the Powder Sieve Machine made of stainless steel + carbon steel or the Powder Sieve Machine made of all carbon steel to save purchase costs.

3. Chemical and other powders with special properties

If you need to deal with special chemical powders, or your powders have special properties (flammable, not in contact with air, toxic, strong adhesion, etc.), such as electrode materials/3D printing materials/graphite powder, etc., choose spraying Specially coated Powder Sieve Machine, special material (plastic/stainless steel) or gas shielded Powder Sieve Machine with better airtightness.

Related Case Studies

-

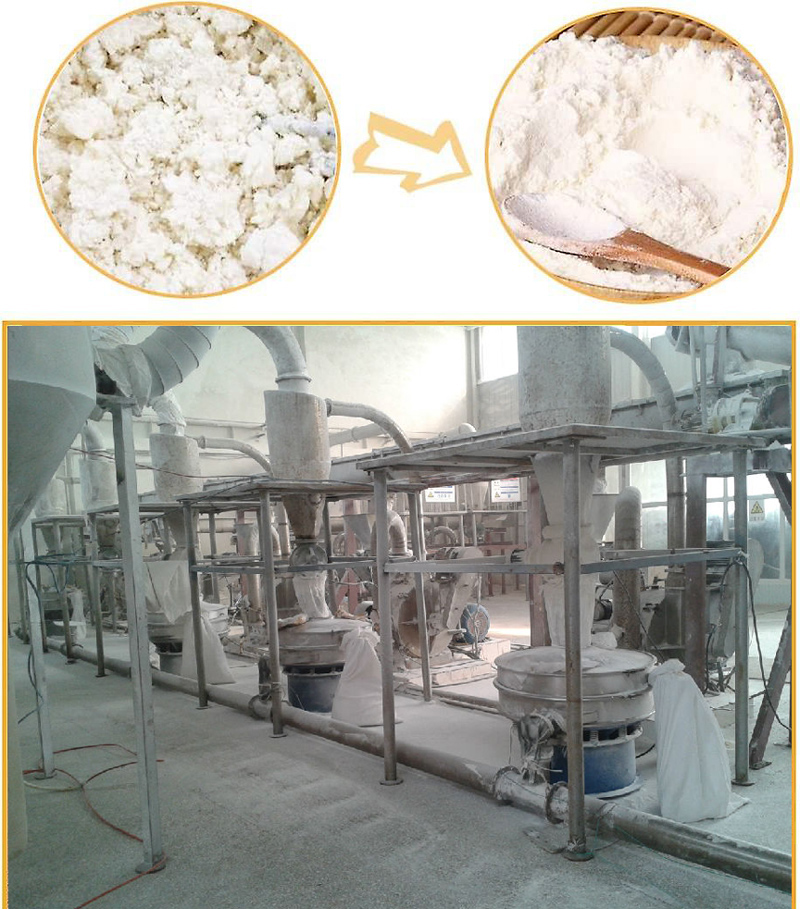

Sieving flour

In the flour processing industry, powder sieve machines can be used to sieve flour to ensure that its quality and fineness meet the requirements. By using sieves with different mesh sizes, impurities, particles and lumps in the flour can be effectively removed, resulting in a fine, uniform flour product.

-

Sieving metal powder

In the metal powder industry, powder sieve machine is used to classify and screen metal powders of different sizes. According to the particle size requirements of the metal powder, a suitable sieve can be selected for screening to remove particles that are too large or too small.

-

Sieving pharmaceutical powder

In the pharmaceutical industry, powder sieve machines are widely used in screening and grading pharmaceutical powders, which can remove impurities, agglomerates and unqualified particles, ensure that pharmaceutical powders meet the required particle size requirements, and ensure product consistency and safety.

-

Remove small stones, sand or clay particles, leaves, dust and other unwanted contaminants in chili powder ...

-

Screen pure milk powder so that it does not have any lumps or unwanted particles, dust problems in the factory ...

-

3D Printing Powders Vibrating Sieve

Maintain the size of the mesh port and stabilize the screening accuracy ...

-

Different types of powder sieve machine

The powder sieve machine can be used for the screening of various powder materials. The powder sieve ...

-

What kinds of materials does the powder separator machine have

What kinds of materials does the powder separator machine have? The rotary vibrating screen is a ...

E-mail: sale@xxdahan.com

Add: 1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.