Sifting Machine

![[field:title/]](/uploads/211116/1-211116095234602.jpg)

Callback

| Mesh size | 2-500 mesh |

| Capacity | 100-3300kg/h |

Ensure materials meet required specifications and remove impurities or foreign matter.

Sort materials into different categories to ensure uniformity and consistency of the final product

The particle separation process can be automated

Introduction of sifting machine

Sifting machine, also known as a sifter machine or a sieving machine, is a mechanical device used to separate and classify materials based on particle size. It consists of a mesh or perforated surface that allows smaller particles to pass through while retaining larger particles.

Sifting machines are widely used in various industries, including food processing, pharmaceuticals, chemicals, minerals, and agriculture. They play a crucial role in quality control, ensuring that materials meet desired specifications and removing impurities or foreign objects.

Function of sifting machine

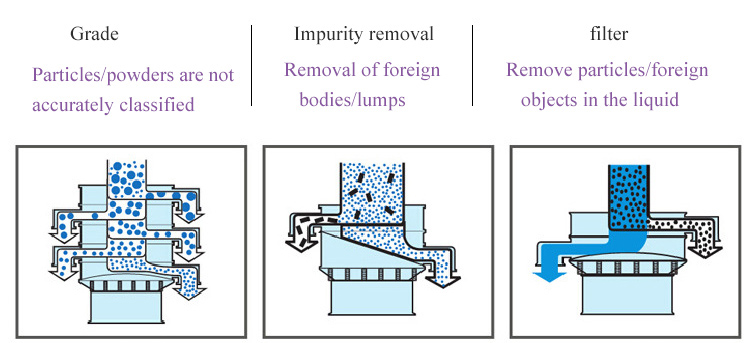

1.Particle Separation: The primary function of a sifting machine is to separate particles of different sizes by passing the material through a mesh or screen with specific openings.

2.Classification: Sifting machines classify materials into different categories based on their particle size, ensuring uniformity and consistency in the final product.

3.De-Dusting: Sifting machines can also remove dust and impurities from materials, improving the overall quality of the product.

4.Scalping: In some applications, sifting machines are used for scalping, which involves removing oversized or undersized particles from the material.

Types of sifting machine

There are several types of sifting machines available, each designed for specific applications and materials. Here are some common types of sifting machines:

1. Vibrating sifting machine: This is a device that uses vibration force to screen materials. It can achieve screening and grading of materials through the vibration generated by the vibration generator. Vibrating sifting machines have various forms and working principles, including inertial vibrating screens, self-centering vibrating screens, eccentric vibrating screens, etc.

2. Ultrasonic sifting machine: It adds an ultrasonic vibrator to the traditional sifting machine, which improves screening efficiency and accuracy through the action of ultrasonic waves. , can separate the powder to 20μm (#635 mesh).

3. Swinging sifting machine: It simulates the action of manual screening, screening and grading materials through swinging motion. The screen size is as fine as 20 microns, and is suitable for applications where the feed particle size is from 1 micron to 20 mm.

4. Air flow sifting machine: uses air flow to sift materials, and is suitable for grading fine powders, such as screening of various dry powders and granular materials. The working principle of the air flow sifting machine is to use the flow of gas to generate vibration to achieve the purpose of screening.

Featured videos

Working principle of sifting machine

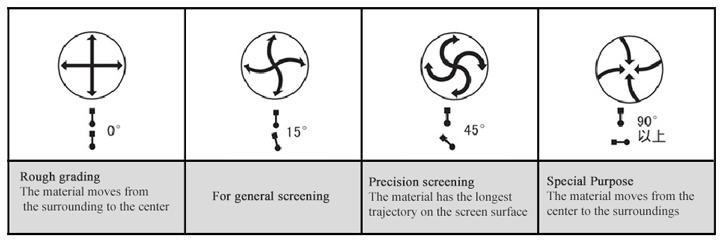

The Sifting machine uses the YZUL vertical vibration motor as the excitation source. The eccentric weight at the upper and lower ends of the vibration motor converts the rotational motion into a horizontal, vertical, and inclined three-dimensional motion, and transmits it to the screen surface of the rotary vibrating screen; the material passes through The material inlet enters the equipment. According to different material screening requirements, the material passes through the screen layer of the screen. In this process, the net cleaning device under the screen-the bouncing ball constantly hits the screen, so that the material on the layer of the screen can be Smooth through screen screening, and effectively solve the problem of material blocking the screen, the screened material and the screened material are discharged from different outlets, so as to achieve the purpose of screening and removing impurities or filtering and grading.

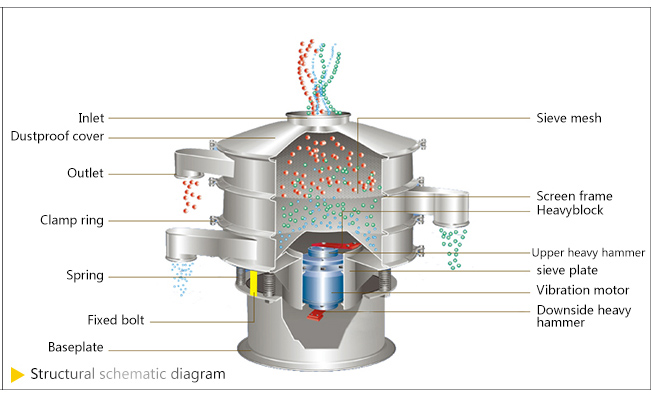

Structure of sifting machine

Sifting machine is composed of dust cover, screen frame, screen, frame, cleaning device, motor (vibration source), damping spring, base and other parts.

Dust cover: It is composed of a feed inlet and an oblique cone, and its lower end is connected with the screen frame to prevent the dust in the workshop from falling into the material when the vibrating screen is working. Commonly used materials are stainless steel, carbon steel and plastic. Etc. 3 kinds of materials.

Screen frame: It is made of steel plate coiled and welded, with bearing rings at the upper and lower ends, and flange rings in the lower part, which are used to fix the structure of the screen components.

Vibration motor: vertical vibration motor, divided into four specifications of 2, 4, 6, 8, and horizontal, the number of vibrations are 2870, 1460, 980, 740RPM, and can be designed as explosion-proof type (flammable and explosive occasions)

Screen: Models are φ600, 800, 1000, 1200, 1500, 1800, etc., and the materials are stainless steel, carbon steel, and plastic.

Cleaning device: clean the blocked materials in the screen mesh to increase the output. It is made of silicone and rubber. You can also choose an ultrasonic cleaning device (635 mesh fine powder with static electricity).

Damping spring: There are 12-20 vibration isolation springs along the vibration transmission body. The base is welded by steel coils. There are access doors and electrical switch seats on the bottom wall. An annular flange is welded on the upper part of the base wall, and the flange is connected with the vibration transmission body through a vibration isolation spring.

Technical parameters of sifting machine

| Model | Diameter mm | Screen area m | Screen size(mesh) | Feeding granularity mm |

| DH-600 | Φ600 | 0.24 | 2-500 | <Φ10 |

| DH-800 | Φ800 | 0.45 | 2-500 | <Φ15 |

| DH-1000 | Φ1000 | 0.67 | 2-500 | <Φ20 |

| DH-1200 | Φ1200 | 1.0 | 2-500 | <Φ30 |

| DH-1500 | Φ1500 | 1.6 | 2-500 | <Φ30 |

| DH-1800 | Φ1800 | 2.43 | 2-500 | <Φ30 |

| DH-2000 | Φ2000 | 3.01 | 2-500 | <Φ30 |

Benefits of sifting machine

1. It can meet the requirements of various powder and particle screening requirements and liquid filtration requirements. The screening is as fine as 500 mesh or 0.028mm, and liquid materials can be filtered to 5 microns.

2. Bounce net cleaning devices are installed under the screens of each layer. By continuously hitting the screens, the materials can be screened smoothly and effectively avoid the problem of material blockage.

3. Impurities and coarse materials are automatically discharged, continuous operation is possible, and the output can reach up to 5 tons/hour

4. 1-5 layers of multi-layer screening can obtain 2-6 kinds of finished products with different specifications.

5. Fully sealed structure, no powder overflow, no liquid overflow.

6. The discharge port can be rotated 360°, and it only takes 3-5 minutes to replace the screen.

Special design of sifting machine

Sifting machine is a common screening equipment. According to its different characteristics and functions, it can be divided into many types, including the following:

1. Added edge type: The screen with an added edge can improve screening efficiency and accuracy and prevent material from overflowing.

2. Gate type: It has an adjustable gate that can control the flow of materials in and out, making it easy to adjust the screening process.

3. Anti-corrosion type: Made of corrosion-resistant materials, suitable for handling corrosive materials or used in corrosive environments.

4. High-frequency type: Using high-frequency vibration, it can achieve efficient screening of fine particles and is often used for the processing of fine powder materials.

5. Mobile: With a mobile base or wheels, it is easy to move and arrange between different workplaces.

6. Silo type: combined with a silo or hopper, it can conveniently store and continuously screen materials.

These different types of sifting machines are suitable for different application scenarios and material characteristics, and the most appropriate type can be selected according to specific needs. Sifting machines are widely used in many industries, such as food processing, chemical industry, mining, building materials, etc., for screening, classifying and removing impurities of granular materials.

Application of sifting machine

Food Industry: Sifting machines are used in the food industry for sifting flour, sugar, spices, and other ingredients to ensure uniform particle size and quality.

Pharmaceutical Industry: In pharmaceutical manufacturing, sifting machines are employed to separate and classify pharmaceutical powders for tablet production and other processes.

Agriculture: Sifting machines are used in agriculture for cleaning and sorting grains, seeds, and other agricultural products.

Chemical Industry: Sifting machines play a crucial role in the chemical industry for separating and classifying chemical powders and granules.

Related Case Studies

-

A corn starch manufacturer uses sifting machine to screen and classify corn starch. They sieve raw cornstarch through a rotary vibrating screen to remove impurities and large particles, while fine cornstarch is collected and separated for subsequent processing steps. This helps improve product quality and production efficiency.

-

A seed research institute uses sifting machines to grade and screen different types of seeds. They put the seed samples through a rotary vibrating sieve, classifying them into different grades based on their size and shape. This helps seed researchers understand the qualities and characteristics of seeds and conduct further research and breeding efforts.

-

A soy milk manufacturer uses a sifting machine to filter ground soy milk. They sieve the ground soy milk through a rotary vibrating screen to remove solid particles and impurities and obtain clean soy milk liquid. This helps improve the taste and quality of soy milk and ensures that the final product meets hygienic standards.

-

In terms of mechanical power, the medium flange motor is adopted ...

-

Effectively remove dust, clumps and foreign matter in the powder ...

-

Quickly separate the impurities in the tea, grading tea of different size & shapes ...

-

Types of rotary Industrial sieving machine

Industrial sieving machine is a high-precision screening machine, whether the material is dry or wet, 0-400 mesh can be screened, and liquid 0-600 mesh can be filtered ...

-

Quartz Powder sifter machine manufacturer

Quartz sieving screen is mainly composed of quartz sand and quartz powder. The particle size below 120 mesh is quartz sand ...

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.