Silica Sand Sieve Machine

Callback

| Screen size: | 2-500 mesh (0.5-0.025mm) |

| Capacity: | 100-3300kg/h |

| Number of layers: | 1-5 layers |

Not easy to plug holes

Can obtain 2-6 different specifications of silica sand at the same time

Automatic discharge, more suitable for assembly line

Introduction of silica sand sieve machine

Silica sand is a wear-resistant and stable mineral raw material after crushing quartz stone. It is widely used in many industries such as foundry, chemical industry, and metallurgy, and different application scenarios have different requirements for the particle size of silica sand. Generally speaking, it can be Divided into ordinary silica sand, refined silica sand and high-purity silica sand, according to the different particle sizes of silica sand, it can be divided into 2 mesh, 4 mesh, 6 mesh, 8 mesh, 16 mesh, 24 mesh, 40 mesh, 70 mesh, 120 mesh, 200 mesh And other specifications. To distinguish such a variety of specifications at high speed and accurately, the use of silica sand sieve machine is essential. Silica sand sieve machine can be installed with 1-6 layers of stainless steel sieves with different meshes, and sieve the silica sand into 2-7 different particle sizes at the same time.

What size mesh for silica sand?

The mesh number of silica sand varies according to the actual use (application industry). Usually, the silica sand used in glass manufacturing should pass through a 20-mesh sieve (0.83mm), and more than 95% should pass through a 100-mesh sieve (0.15mm). The silica sand manufacturer is as fine as 200 mesh (0.07mm).

Common specifications of silica sand are: 1-2mm, 2-4mm, 4-8mm, 8-16mm, 16-32mm, 10-20 mesh, 20-40 mesh, 40-80 mesh, 100-120 mesh, 200 mesh, 325mesh .

SiO2≥99—99.5%Fe2O3≤0.02—0.015%

What is the purpose of Silica Sand Sieve Machine?

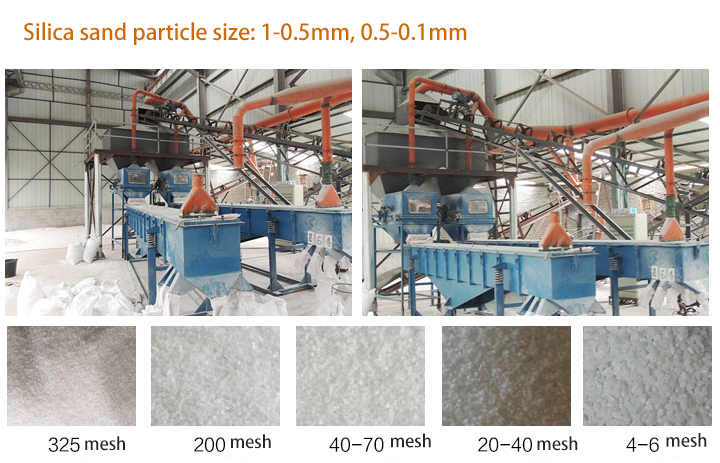

1. Rough processing: (generally 1-0.5mm, 0.5-0.1mm can be prepared)

Select quartz sand mines with better texture for preliminary mining; the mined quartz sand is firstly crushed with a jaw crusher, and the crushed materials are transported to the silica sand linear sieve for primary screening through a belt conveyor, and the large particles are returned to the The jaw crusher is used for secondary crushing, and the small particles are transported by the belt conveyor to the roller crusher for secondary crushing. The quartz sand crushed by the roller crusher is sent to the fine screening linear vibrating screen for screening and classification.

2. Fine processing: (50-480 mesh)

The quartz sand 1-0.5mm and 0.5-0.1mm grades of rough processing can be vibrating milled by vibrating mill/vibrating rod mill. After grinding, it can be sieved by silica sand sieve machine to prepare about 100-300 mesh. Fine powder; if you want to achieve finer grinding, you generally use a high-efficiency Raymond mill for grinding, and there is no need to sieve the powder. The Raymond mill is generally equipped with an analyzer, and it can be prepared by loading a finished product grade analyzer. 300- 500 mesh finished products.

Featured videos

-

Sieving silica sand

-

Sieving silica sand powder

Benefits of silica sand sieve machine

1. According to the particle size requirements of silica sand, it can classify silica sand with different meshes, and can achieve up to 7 grades of separation.

2. Screen specifications are: 0.5-1mm, 1-2mm, 2-4mm, 4-8mm, 8-16mm, 16-32mm, 10-20 mesh, 20-40 mesh, 40-80 mesh, 100-250 mesh , can meet a variety of application requirements, and ensure that the particle size of silica sand meets the requirements of use.

3. Flange design can be made on the feed inlet to connect the feeding equipment, so that the quartz sand can enter and discharge automatically, saving labor cost and time.

4. The upper cover of the equipment is designed with a dust removal device, which can prevent a large amount of dust on the work site and improve the working environment of the workers.

Technical parameters of silica sand sieve machine

50-480 mesh silica sand can be selected:

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

1-0.5mm, 0.5-0.1mm silica sand can be selected:

| Model | Layer | Screening Area (mm) |

Mesh Size (mesh) |

Particle Size (mm) |

Capacity (t/h) |

Power (kw) |

Vibration Direction Angle (°) |

Screen Inclination (°) |

Dual Amplitude |

| DZSF-520 | 1-6 layers | 500*2000 | 2-400 | 0.074-10 | ≤3 | 0.37×2 | 45-60 | 0-70 | 3-4.5 |

| DZSF-525 | 500*2500 | ≤5 | 0.37×2 | ||||||

| DZSF-612 | 600*1200 | ≤8 | 0.37×2 | ||||||

| DZSF-1020 | 1000*2000 | ≤12 | 0.75×2 | ||||||

| DZSF-1025 | 1000*2500 | ≤16 | 0.75×2 | ||||||

| DZSF-1030 | 1000*3000 | ≤20 | 1.1×2 | ||||||

| DZSF-1224 | 1200*2400 | ≤23 | 1.5×2 | ||||||

| DZSF-1525 | 1500*2500 | ≤28 | 1.5×2 | ||||||

| DZSF-1530 | 1500*3000 | ≤32 | 2.2×2 |

Related cases

Silica Sand Sieve Machine has a wide range of applications, not only limited to the screening of silica sand, but also can be used for material screening in other industries. It can be connected to the production line for use, and different types and hole types of screens can also be selected according to the actual usage.

1. Punching screen: the shape of the mesh is square or round, which is used to process large particles of silica sand, which is strong and not easy to break.

2. Metal braided wire screen: the mesh is mostly square, which is used to screen fine silica sand powder/fine sand. Screen surface damage caused by overweight material.

-

Single and multiple layers can be used at the same time, up to 5 layers ...

-

The mesh is not deformed, the screen has a long service life and high efficiency. ...

-

What is traditional sand sieving method?Why choose sand screening machine?

The traditional sand screening method only relies on a circular or inclined square screen, and uses manpower ...

-

Different applications of silica sand sieve machine

Silica sand is an important industrial mineral raw material, non-chemical dangerous goods, widely used in glass ...

-

Common faults and solutions for vibro sifter

As the most common fine screening equipment, the vibro sifter has high screening precision ...

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.