Silicon powder for test sieve

Silicon powder for test sieve is a fine powder composed of silicon particles that are commonly used in various industrial applications, including electronics, metallurgy, and materials science. When it comes to testing the particle size distribution of silicon powder, a test sieve is a crucial tool used to accurately determine the particle sizes present in the powder sample.

Silica powder for test sieve properties

Particle Size: Silicon powder can vary in particle size distribution, ranging from coarse particles to ultra-fine particles, depending on the manufacturing process and intended application.

Purity: High-purity silicon powder is often required for applications in the semiconductor industry, where even trace impurities can impact performance.

Color: Silicon powder is typically gray or dark gray in color, reflecting its metallic properties.

Density: Silicon powder has a relatively high density, which can impact its flow characteristics and packing density.

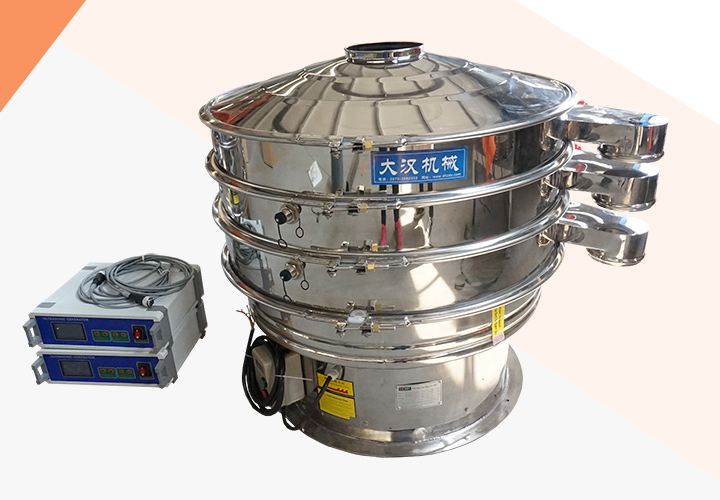

Test Sieve for Silicon Powder Analysis A test sieve is a precision instrument used to separate particles based on size. When analyzing silicon powder, a test sieve helps determine the particle size distribution, which is crucial for quality control and process optimization. The test sieve consists of a woven mesh screen mounted in a frame, with openings of various sizes to allow particles of specific sizes to pass through.

Procedure for Testing Silicon Powder with a Test Sieve

Sample Preparation: A representative sample of the silicon powder is collected for analysis.

Sieve Setup: The test sieve with the desired mesh size is selected based on the expected particle size range of the silicon powder.

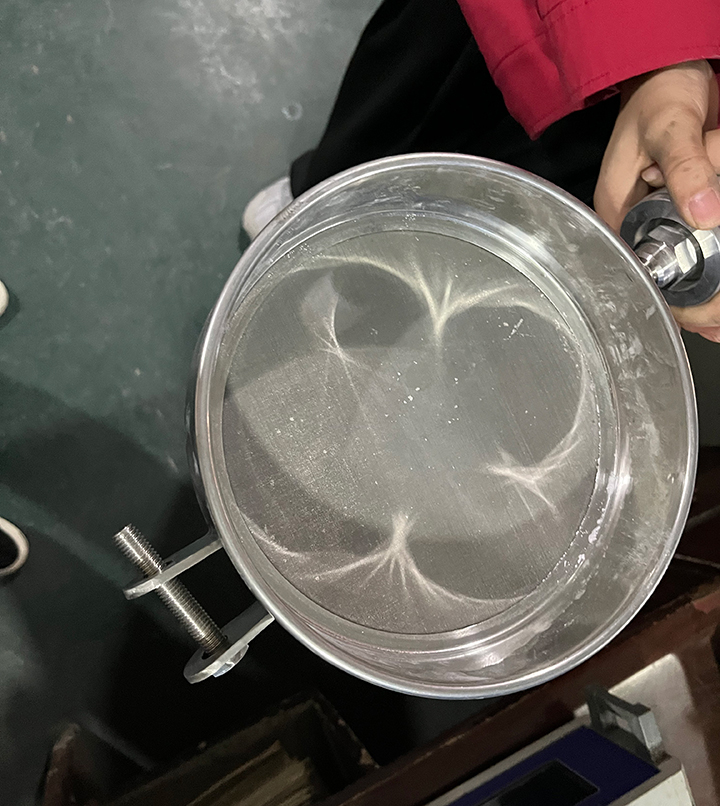

Sieving Process: The silicon powder sample is placed on the test sieve, and the sieve is then shaken or vibrated to allow particles to pass through the mesh.

Particle Analysis: After sieving, the retained particles on each sieve are weighed or measured to determine the particle size distribution.

Data Interpretation: The results are analyzed to understand the particle size distribution of the silicon powder sample.

Importance of Test Sieve Analysis for Silicon Powder

Quality Control: Test sieve analysis ensures that the silicon powder meets the required particle size specifications for its intended application.

Process Optimization: By understanding the particle size distribution, manufacturers can optimize production processes to achieve desired material properties.

Research and Development: Test sieve analysis is essential in research and development to study the characteristics of silicon powder and optimize formulations.

Regulatory Compliance: Industries such as pharmaceuticals and electronics may have strict regulations regarding particle size distribution, making test sieve analysis crucial for compliance.

Considerations for Test Sieve Analysis

Mesh Size: Selecting the appropriate mesh size is critical to ensure accurate particle size analysis.

Equipment Calibration: Regular calibration of the test sieve and sieving equipment is necessary to maintain accuracy.

Sample Preparation: Proper sample preparation techniques are essential to obtain reliable and reproducible results.

Data Interpretation: Understanding the results of the test sieve analysis and their implications for the application of silicon powder is key to making informed decisions.

In conclusion, test sieve analysis plays a vital role in characterizing the particle size distribution of silicon powder. By utilizing a test sieve, manufacturers can ensure the quality, consistency, and performance of silicon powder in various industrial applications.

-

Granules, powders, and paddle materials can be used

-

Can sieve ultra-fine powder down to 20 microns without clogging the sieve holes

-

Graphite Powder Sieving Machine

It can be used in single layer or multiple layers, and 6 different grades of graphite ...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials, easy agglomeration....

-

Konjac fine powder ultrasonic vibrating screen

Konjac fine powder ultrasonic vibrating screen is a high-precision fine particle screening equipment. The equipment uses the up and down excitation force....

-

Paint raw materials sieve with vibro shaker

Paint raw materials sieve with vibro shaker The quality and performance of paint largely depend on the selection and screening of raw materials.....

-

Dietary Supplements for Vibrating Sieve

Dietary supplements vibrating sieve As an efficient and reliable sieving equipment, it plays an important role in the production of dietary supplements. Through high-frequency vibra ...

-

Aqua Feed For Ultrasonic Vibrating Screen

The aquatic feed ultrasonic vibrating screen uses advanced ultrasonic technology to achieve an efficient screening process through high-frequency weak vibration. Compared with tradi ...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.