Soy product vibrating screen

Soy product vibrating screen is a screening device specially designed for the production of soy products. It can effectively separate the dregs and impurities in soy milk, thereby effectively improving the quality of soy products. Soy products include tofu, soy milk, dried tofu, etc., and in the production of soy products, it is often necessary to screen the dregs in soy milk to obtain delicate soy milk or dregs products. When choosing a soy product vibrating screen, you should consider various factors and choose equipment that suits your production needs.

Soy product vibrating screen video

How does the soy product vibrating screen work

The working principle of soy product vibrating screen is to use the vibration generated by the vibration motor to make the screen box produce horizontal reciprocating motion or three-dimensional motion. Soy milk in the screen box is subjected to the combined action of the exciting force and gravity, producing jumping motion. Liquid (soy milk) smaller than the screen hole passes through the screen, while solid particles such as bean dregs larger than the screen hole are retained on the screen surface, thus achieving solid-liquid separation.

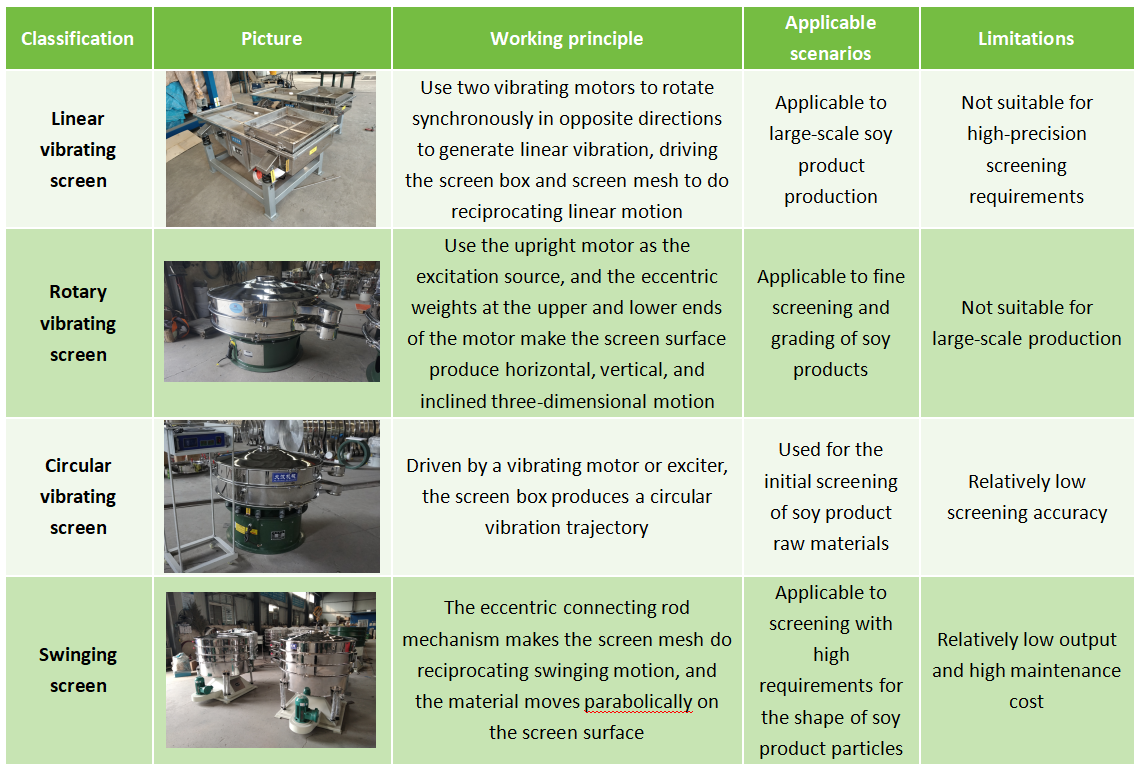

Classification of soy product vibrating screens

Advantages of vibrating screen for soy products

1. Solve the problem of stickiness of soy products: Use high-frequency vibration technology to make the screen produce high-frequency micro-vibration, destroy the sticky structure of the material, make the material jump quickly on the screen, reduce the material adhesion time, and reduce the possibility of clogging of the screen hole. Some advanced vibrating screens can vibrate thousands of times per minute to solve the problem of stickiness.

2. Reduce the risk of soy product deterioration: For some temperature-sensitive soy products, low-temperature screening technology is used to cool the material during the screening process, reduce the material temperature, inhibit the growth and reproduction of bacteria, and extend the shelf life of the material. Set a cooling pipe on the surface of the screen to reduce the screen temperature by circulating coolant.

3. Avoid the problem of uneven soy products: Set a buffer device at the feed end of the screen so that large-particle soy product materials will first pass through the buffer device when entering the screen, reduce the impact on the screen, and extend the service life of the screen.

4. Food grade material: All parts of the vibrating screen that come into contact with the material, such as the screen, screen box, and discharge port, are made of materials that meet food hygiene standards, such as food grade stainless steel, food grade plastic, etc., to ensure that there is no contamination of soy products.

Recommended mesh number of vibrating screen for soy products

Generally speaking, the mesh number range of vibrating screen for soy products is between 100-300 mesh.

100-150 mesh: suitable for making tofu, bean curd, and other soy products that require a higher degree of soy milk fineness.

150-200 mesh: suitable for making soy milk drinks, soy milk, etc.

200-300 mesh: suitable for making bean skin, dried bean curd, and other products that require higher purity soy milk.

Application of soy product vibrating screen

1. Soy milk production line: Soy product vibrating screen can be used to screen the soy milk after grinding soybeans, remove the dregs, and obtain delicate soy milk products. The dregs can also be graded to separate the dregs of different particle sizes for subsequent processing and utilization.

2. Tofu production workshop: Soy product vibrating screen can be used to process soy milk, remove the dregs in it, and ensure the delicate texture of tofu. For the dregs, the soy product vibrating screen can help grade them and divide the dregs into products of different particle sizes as needed.

3. Dried tofu production factory: Soy product vibrating screen can be used to screen the dregs in soy milk to ensure the quality of dried tofu raw materials, and can also be used to grade dried tofu particles to obtain uniform products.

4. Soy product processing plant: Soy product vibrating screen can be used to screen the raw materials of soy products, remove impurities, and ensure product quality. It can also be used for the final screening process before packaging soy products to ensure the cleanliness and quality of the products.

Soy product vibrating screen is an indispensable equipment in the soy product production line. Through its unique structural design and working principle, it effectively solves various problems encountered in the production process of soy products and improves the quality of soy products. When choosing a soy product vibrating screen, you should choose the appropriate equipment based on the characteristics of soy milk, production scale and other factors.

-

Screening and filtering of particles, powders, liquids and other materials

-

Filter wheat flour and remove unwanted particles to ensure product quality

-

Moxa linear vibrating screen

Moxa linear vibrating screen is a screening device specially designed for moxa processing. It is...

-

Carbon material vibrating screen

Carbon material vibrating screen is a device specially used for screening carbon materials. Carbon...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Titanium powder vibrating screen

Titanium powder vibrating screen is a device specially used for screening titanium powder. It is...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.