Swing Vibrating Screen

![[field:title/]](/uploads/250228/6-25022Q00209417.jpg)

Callback

Swing Vibrating Screen is a high-efficiency screening machine specially designed to meet the needs of large-scale and high-precision screening. It is mainly used for screening, grading and separation of granular materials.

Screening mesh: 2-500 mesh

Output: 0.5-60 tons/hour

Eccentricity: 25-40 (mm)

Drive: 120-360 (rpm)

Material: carbon steel, stainless steel

Application range: chemical and new materials, metallurgy, mineral powder, food, abrasive and other industries

Applicable materials: machine-made sand, silica sand, plate sand, quartz sand, ceramsite sand, calcite, calcium carbonate, bentonite, petroleum coke, mineral powder, etc.

What is a swing vibrating screen?

Swing Vibrating Screen is a high-precision fine-particle screening equipment, also known as a reciprocating vibrating screen. It achieves material screening through a special motion mode. The screen box, driven by the motor, performs a complex plane gyratory motion. This motion trajectory is similar to an ellipse, causing the material to produce a regular, three-dimensional tumbling motion on the screen surface.

What is the difference between a swing vibrating screen and a vibrating screen?

|

Features |

Swing vibrating screen |

Vibrating screen |

|

Working principle |

Imitating manual screening, low-speed swing motion |

High-frequency vibration generated by vibration motor |

|

Image |

|

|

|

Movement mode |

Plane swing, rotational motion |

Up and down vibration or three-dimensional vibration |

|

Screening efficiency |

High, suitable for fine materials |

High, suitable for large-scale coarse screening |

|

Material handling |

Gentle, suitable for fragile and sticky materials |

Very violent, suitable for hard and non-fragile materials |

|

Noise level |

Low, stable operation |

High, vibration produces large noise |

|

Screen life |

Long, due to uniform force |

Short, easy to wear due to high-frequency vibration |

|

Applicable scenarios |

Fine industries such as food, medicine, and chemicals |

Heavy industries such as mining, building materials, and metallurgy |

|

Maintenance cost |

Low, simple structure |

High, vibrating parts are easy to wear |

|

Output |

Medium and low output, focus on quality |

High output, focus on efficiency |

Swing vibrating screen is more suitable for scenarios where material integrity needs to be protected or high-precision screening is required, because its movement is similar to manual screening and causes less damage to the material.

Vibrating vibrating screen is more suitable for industrial scenarios with large processing volume and low precision requirements, because of its high vibration frequency and fast screening speed.

How does the swing vibrating screen work?

Swing vibrating screen mainly uses the difference between the particle size of the material and the aperture of the screen to screen. When the screen box starts to move, the material is thrown up and rolls, slides and jumps on the screen surface. In this process, smaller particles can pass through the screen holes, while larger particles are left on the screen surface and gradually move toward the discharge port as the screen box moves, thereby achieving the separation of materials of different particle sizes.

Swing Vibrating Screen Video

What types of swing vibrating screens are there?

Circular Swing Vibrating Screen: The screen box moves in a circular motion, which is suitable for screening materials with smaller particle sizes and has high screening accuracy. The screening efficiency is generally 93%~95%, which is suitable for grading, stripping, dehydration and other purposes.

Square swing vibrating screen: The screen box moves back and forth in a straight line, and the material is thrown on the screen surface many times to achieve screening. The processing capacity is several times that of the traditional vibrating screen, which is suitable for screening sand, gravel, aggregates, etc.

|

Type |

Appearance shape |

Movement mode |

Applicable materials |

Main features |

Applicable industries |

|

Circular swing screen |

Circular |

360° circular swing |

Applicable to ultra-fine powders and light materials |

Simulated manual screening, high screening accuracy |

Fine chemicals, medicine, food, etc. |

|

Square swing screen |

Rectangular or square |

Reciprocating swing, large screen surface |

Applicable to large particles or irregular materials |

Large processing capacity, high screening accuracy |

Sandstone, metallurgy, chemical industry, grain, etc. |

|

Linear swing screen |

Rectangular |

Reciprocating motion back and forth |

Applicable to fine screening of powder and granular materials |

Suitable for multi-layer screening, good screening effect |

Food, chemical industry, medicine, environmental protection, etc. |

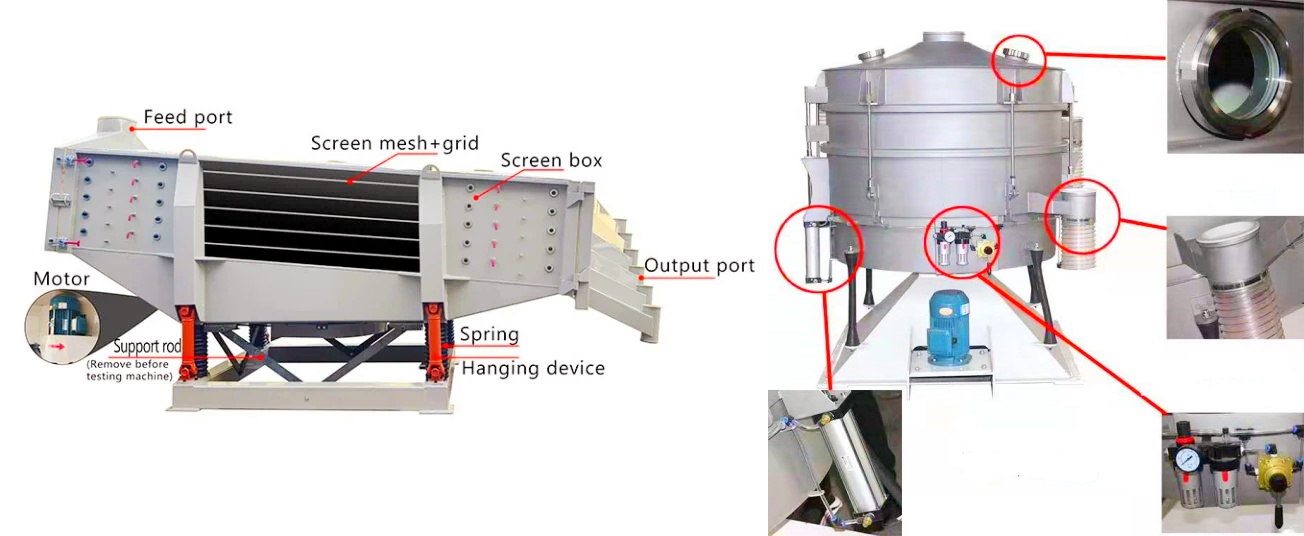

Structures Of Swing Vibrating Screen

Swing vibrating screen machine mainly comprises the feed port, screen box, drive device, screen frame, support frame, vibration reduction device, discharge port, and other components.

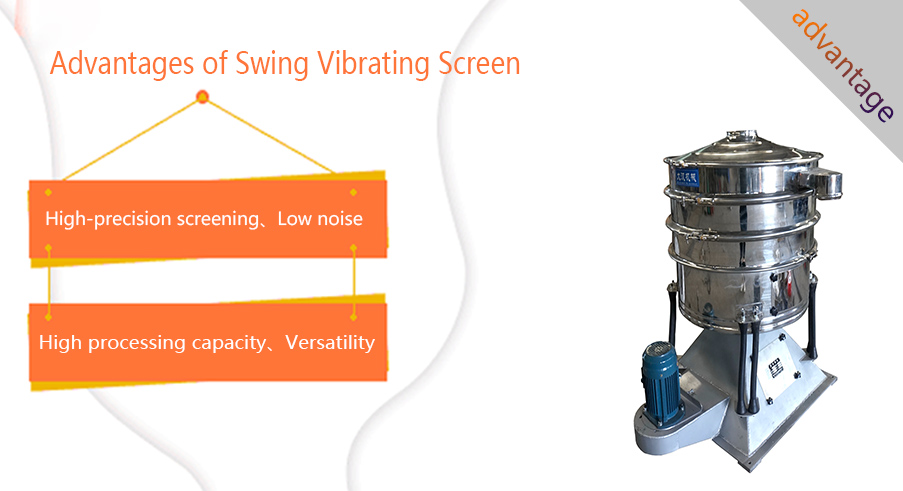

Advantages of Swing Vibrating Screen

1. High-precision screening: The movement of the swinging screen allows the material to fully roll and jump on the screen surface.

2. High processing capacity: Due to its special motion trajectory and efficient screening method, the swinging screen can process a large amount of material in a short time.

3. Low noise: The support device of the swinging screen can effectively reduce the vibration and noise, and the noise generated in the working environment is relatively low.

4. Versatility: By replacing screens with different mesh sizes and adjusting motion parameters, the swinging screen can adapt to the screening of materials of different particle sizes and properties.

Specifications

|

Model |

Screen size |

Screening area |

Screen inclination |

Layers |

Power |

Number of turns |

Case travel |

|

DH1536 |

1.5*3.5 m |

4.5-9m2 |

5-8 |

1-10 |

5.5 |

180-260 |

25-60mm |

|

AH2040 |

2.0*4.0 m |

8-9m2 |

5-8 |

1-10 |

7.5 |

180-260 |

25-60mm |

What is the purpose of a swing vibrating screen?

Fine screening: used to separate fine particles or powdered materials, such as flour, powdered sugar, starch, medicinal powder, etc., to ensure uniform particle size of the materials.

Fragile material handling: suitable for screening fragile or fragile materials (such as granular food, crystalline materials), because its low-speed swinging motion will not destroy the material structure.

Viscous or moist material screening: processing materials with strong viscosity or high moisture content (such as chemical raw materials, Chinese medicine powder), because its movement can effectively prevent the screen from clogging.

High-precision classification: in scenarios where multi-layer classification is required, it is used to accurately classify materials according to different particle sizes, such as separating powders of different specifications in the pharmaceutical and cosmetic industries.

Special industry applications: widely used in food processing (such as seasoning, milk powder screening), pharmaceutical manufacturing (such as raw material screening), chemical production (such as pigment, coating screening) and other industries.

Recommended mesh number of the swing screen

1. Material with high screening accuracy (such as pharmaceutical powder, food additives) - 100-400 mesh is recommended.

2. Material with large particles that require efficient screening (such as sand and gravel, plastic particles) - 5-80 mesh is recommended.

3. Lightweight or easily agglomerated materials - a higher mesh number (200-400 mesh) can be selected, and the addition of ultrasonic or airflow auxiliary functions can be considered.

Recommended mesh for different materials

|

Material type |

Recommended mesh range (mesh) |

Remarks |

|

Flour, starch |

60-200 mesh |

Fine powder screening to prevent agglomeration |

|

Traditional Chinese medicine powder, food additives |

80-300 mesh |

Suitable for fine screening |

|

Chemical powder (such as calcium carbonate, aluminum oxide) |

100-400 mesh |

High particle uniformity requirements |

|

Quartz sand, metal powder |

10-200 mesh |

Suitable for coarse particles and fine powder |

|

Plastic particles, rubber powder |

10-80 mesh |

Suitable for particle screening |

|

Ceramic powder, glass powder |

120-400 mesh |

Suitable for ultra-fine screening |

|

Feed, grain |

5-50 mesh |

Suitable for pellet feed, beans, etc. |

|

Compound fertilizer, chemical fertilizer |

4-60 mesh |

Suitable for particle grading |

How to fix a swing vibrating screen?

Power-off operation: Be sure to cut off the power supply before repair to ensure safety.

Regular maintenance: Regularly check the screen, bearings, seals and other wearing parts and replace them in time.

Lubrication maintenance: Regularly add lubricating oil to the bearings and transmission parts to reduce wear.

Cleaning equipment: Clean the screen and the inside of the equipment after each use to prevent material accumulation.

-

Screening and filtering of particles, powders, liquids and other materials

-

Filter wheat flour and remove unwanted particles to ensure product quality

-

Diamond Vibrating Screen

Diamond vibrating screen is a device used for screening and grading diamond particles. Through vibration force and screen structure ...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials, easy agglomeration, low melting point, ...

-

Sugarcane Juice Bioethanol Vibro Sifter

Sugarcane Juice Bioethanol Vibro Sifter is a device for filtering sugarcane juice, mainly used for sugarcane juice filtration in bioethanol industry. ...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.