Carbon fiber for Powder Sieving Machine

As a light, high-strength and rigid material, carbon fiber is widely used in aerospace, automobile manufacturing, sports equipment and other fields. In the production and processing of carbon fiber, powder sieving machine plays an important role for sieving and classifying carbon fiber to control the particle size distribution and purity of the powder.

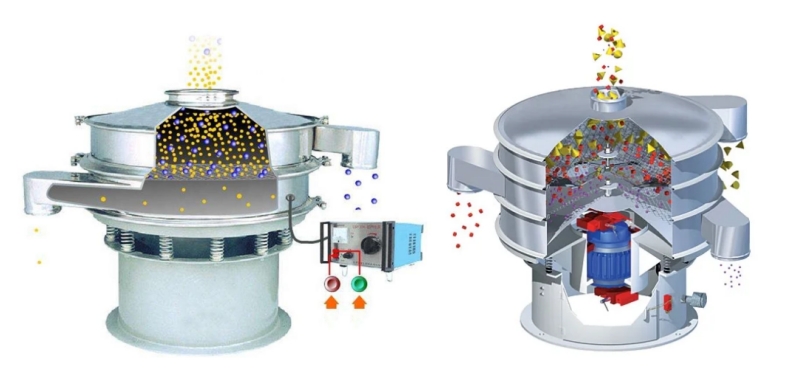

First of all, carbon fiber for powder sieving machine needs to consider its special properties. The particle size of carbon fiber powder is usually small and light, which makes it easy to fly and scatter during the screening process. Therefore, the design of the powder sieving machine needs to take into account the fluidity and dispersion of carbon fiber powder, and use appropriate screen materials and mesh sizes to prevent leakage and cross-mixing of carbon fiber powder. In addition, the powder sieving machine also needs to have good sealing performance to prevent dust from overflowing and polluting the environment.

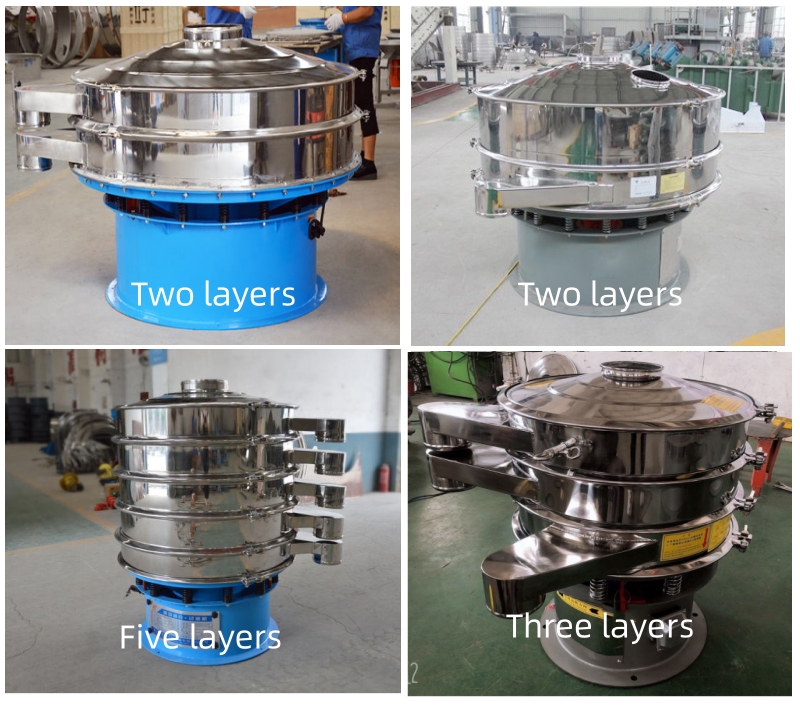

Secondly, the carbon fiber for powder sieving machine needs to ensure screening accuracy and efficiency. Due to the small particle size and high dispersion requirements of carbon fiber powder, traditional screens may not be able to meet the requirements. Therefore, powder sieving machines usually use high-precision screens, such as stainless steel wire mesh or screens made of special alloy materials, which have fine mesh holes and good wear resistance. In addition, the vibration frequency and amplitude of the powder sieving machine are adjustable to produce appropriate sieving force and fluidity, ensuring the uniform distribution and flow of carbon fiber powder on the screen.

In addition, carbon fiber for powder sieving machine also needs to consider purity and impurity control. Carbon fiber, as a high-purity material, has a low tolerance for impurities and contaminants. Therefore, during the screening process, it is necessary to ensure that the cleaning performance of the sifting machine is good, and the screen and sifting machine should be cleaned and maintained regularly to ensure the purity and quality of carbon fiber powder.

In addition, the operation and control system of the powder sieving machine are also key factors affecting the carbon fiber screening effect. The powder sieving machine needs to have adjustable vibration force and sieving time to adapt to the sieving requirements of different powders. At the same time, the powder screening machine should also be equipped with a suitable collection device to collect and separate the screened carbon fiber powder to avoid secondary contamination and loss of the powder.

As an important tool in the carbon fiber processing process, powder sieving machine plays an irreplaceable role. Its efficient, accurate and reliable screening and grading functions provide key support for the processing and application of carbon fiber, improving production efficiency and product quality. With the wide application and growing demand of carbon fiber in various fields, the development of powder sieving machine will also be more rapid.

-

Removes all oversized contamination or agglomerates from powder ...

-

Bentonite for Powder Sieving Machine

The application of powder sieving machine in the field of bentonite has the advantages of efficient screening....

-

Nano Alumina for Powder Sieving Machine

The application of powder sieving machine in the field of nano Alumina can achieve precise control of particle size...

-

Nano Silica for Powder Sieving Machine

The application of powder sieving machine in the field of Nano Silica has the advantages of particle size control...

-

Nano Carbon Black for Powder Sieving Machine

Nano carbon black offers significant advantages when utilized in powder sieving machines. Its unique properties...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.