Carbon material vibrating screen

Carbon material vibrating screen is a device specially used for screening carbon materials. Carbon materials, such as graphite, carbon fiber, activated carbon, etc., can be widely used in new energy, material science and other fields due to their unique physical and chemical properties, and have high requirements for purity and particle size distribution. In order to ensure the purity and particle size distribution of these materials, fine screening is required, and the carbon material vibrating screen is designed for this purpose.

Carbon material vibrating screen video

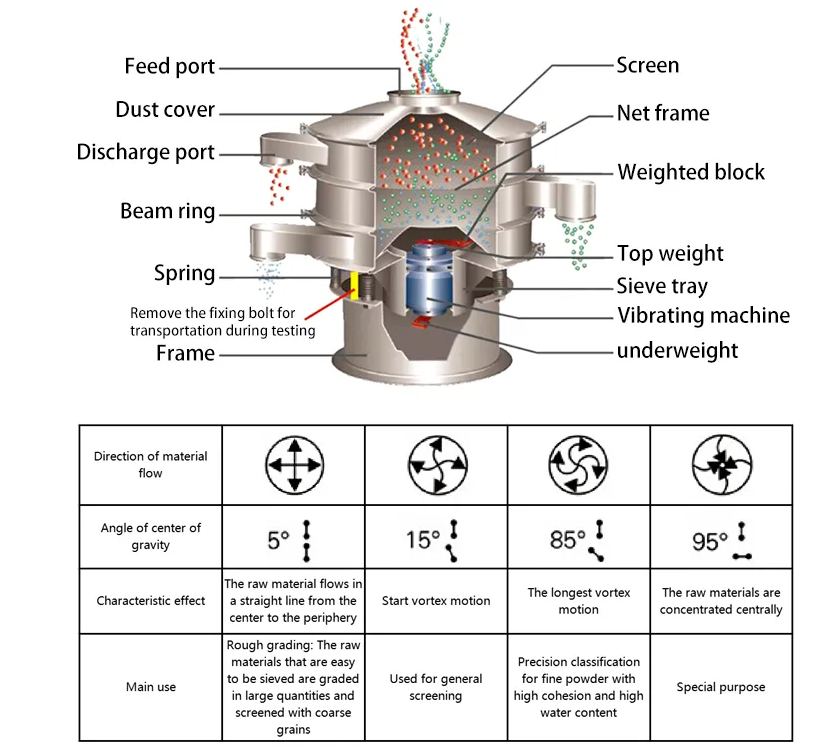

How does the carbon material vibrating screen work

Carbon material vibrating screen uses the vibration generated by the vibration motor to make the screen box produce horizontal reciprocating motion or three-dimensional motion. The carbon material on the screen surface is subjected to the combined action of the exciting force and gravity, producing a jumping motion. The particles smaller than the screen hole pass through the screen, while the particles larger than the screen hole are retained on the screen surface, thus achieving screening.

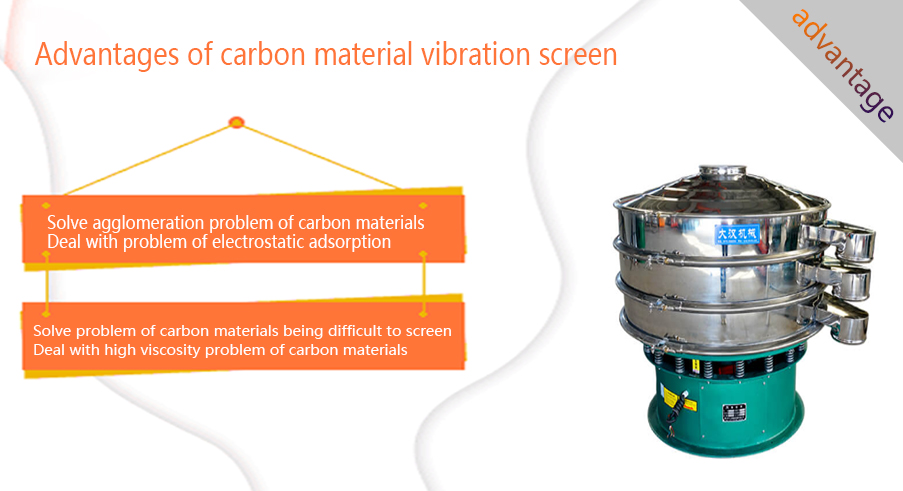

Advantages of carbon material vibration screen

1. Solve agglomeration problem of carbon materials: Due to the large specific surface area and high surface energy, some carbon materials are prone to agglomeration. The vibration screen can set high-frequency vibration to make the agglomerated carbon material particles collide and disperse with each other under the action of high-frequency vibration, thereby effectively breaking the agglomeration.

2. Deal with problem of electrostatic adsorption: Use anti-static screen materials and equipment components. These materials can effectively reduce the generation of static electricity between carbon materials and equipment, and reduce the impact of static adsorption on screening.

3. Solve problem of carbon materials being difficult to screen: Use a multi-layer screen structure. Screens of different mesh sizes are arranged from top to bottom, which can realize multi-level screening of carbon materials, so that fine powders of different particle size ranges can be separated more accurately and the screening accuracy can be improved.

4. Dealing with high viscosity problem of carbon materials: The carbon material vibrating screen can increase the vibration intensity, so that the sticky carbon material can overcome its own viscosity and cohesion under the action of greater vibration force, maintain good fluidity on the screen surface, and avoid material accumulation and adhesion on the screen surface.

Recommended mesh number of carbon material vibrating screen

Coarse-grained carbon material: the mesh number is generally between 40-100 mesh, mainly used in filling materials, casting and other fields.

Medium-grained carbon material: the mesh number is generally between 100-200 mesh, widely used in battery materials, composite materials and other fields.

Fine-grained carbon material: the mesh number is generally above 200 mesh, used in electronics, medicine and other industries with higher requirements.

Application of carbon material vibrating screen

1. Activated carbon production: Carbon material vibrating screen is used to grade and screen activated carbon particles of different particle sizes to ensure uniform product particle size and meet the requirements of activated carbon adsorption performance in different application scenarios. Activated carbon of different particle sizes has different adsorption effects on different pollutants.

2. Graphite processing: Carbon material vibrating screen can screen graphite particles according to different mesh sizes to obtain graphite powder products of different fineness, which are used in batteries, lubrication, conductive materials and other fields. For example, battery-grade graphite powder has high requirements for particle size and needs to be accurately screened by vibrating screen.

3. Carbon nanotube production: Carbon nanotubes can be screened by carbon material vibrating screen to separate carbon nanotubes of different lengths and diameters to meet the specific requirements of carbon nanotube performance in electronics, composite materials and other fields.

4. Silicon carbide production: Screen silicon carbide raw materials or finished products to remove impurities and unqualified particles, ensure the quality and performance of silicon carbide products, and meet the needs of abrasives, refractory materials, semiconductors and other industries.

Carbon material vibrating screen plays an important role in the production and application of carbon materials. Through screening, the purity and particle size distribution of carbon materials can be guaranteed and the performance of products can be improved. When choosing a carbon material vibrating screen, the appropriate equipment should be selected according to factors such as the characteristics of the carbon material and the screening requirements.

-

Screening and filtering of particles, powders, liquids and other materials

-

Filter wheat flour and remove unwanted particles to ensure product quality

-

River sand linear vibrating screen

River sand linear vibrating screen is a commonly used screening equipment, which is used to...

-

Chemical liquid vibrating screen

Chemical liquid vibrating screen is a device used for solid-liquid separation or liquid filtration...

-

Titanium powder vibrating screen

Titanium powder vibrating screen is a device specially used for screening titanium powder. It is...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.