Ceramic slurry vibrating screen

Ceramic slurry vibrating screen is a specialized type of vibrating screen designed for filtering and separating ceramic slurries in industrial processes. Ceramic slurries consist of ceramic particles suspended in a liquid medium, and the vibrating screen is used to remove impurities, oversize particles, and ensure a uniform particle size distribution in the final product. This equipment plays a critical role in industries such as ceramics manufacturing, mining, and chemical processing where ceramic slurries are used in various applications.

Ceramic slurry vibrating screen function and Importance

Particle Separation: The primary function of the ceramic slurry vibrating screen is to separate ceramic particles of different sizes within the slurry. This separation process is essential for ensuring product quality and consistency.

Impurity Removal: The vibrating screen removes impurities, such as debris, agglomerates, and foreign particles, from the ceramic slurry, ensuring a clean and high-quality final product.

Uniform Particle Size Distribution: By efficiently separating particles based on size, the vibrating screen helps achieve a uniform particle size distribution in the ceramic slurry, which is crucial for producing high-quality ceramic products.

Process Efficiency: The vibrating screen enhances process efficiency by quickly and effectively filtering the ceramic slurry, reducing processing time and improving overall productivity.

Ceramic slurry vibrating screen Working Principle

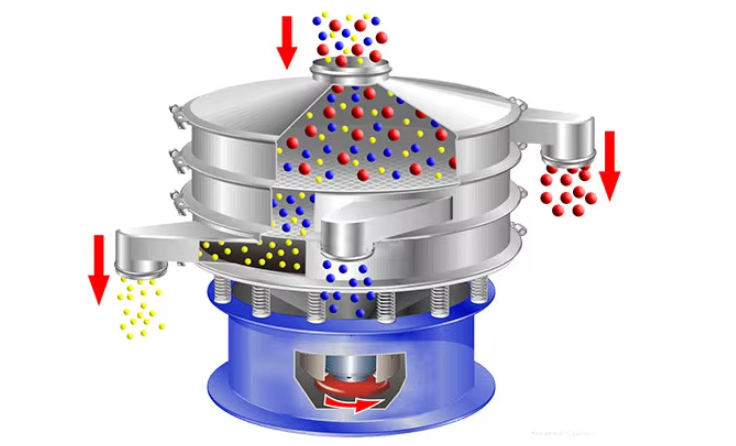

The ceramic slurry vibrating screen operates based on the principles of vibration and screening. Here is an overview of how it typically works:

Vibration Generation: The vibrating screen is equipped with a vibration motor or an eccentric weight system that generates vibrations. These vibrations cause the screen deck to oscillate, creating a shaking motion.

Screen Deck: The ceramic slurry is fed onto the screen deck, which is usually made of wire mesh or perforated plates with specific opening sizes. The slurry flows over the screen deck, and the ceramic particles are separated based on their size.

Particle Separation: As the slurry moves across the vibrating screen, the ceramic particles are sorted according to their size. Smaller particles pass through the openings in the screen deck, while larger particles are retained on the surface.

Discharge of Clean Slurry: The clean ceramic slurry, free from impurities and oversize particles, passes through the screen deck and is collected for further processing or use. The separated particles are typically collected and disposed of separately.

Benefits of a Ceramic Slurry Vibrating Screen

Improved Product Quality: By removing impurities and ensuring a uniform particle size distribution, the vibrating screen helps improve the quality of ceramic products manufactured using ceramic slurries.

Increased Efficiency: The vibrating screen enhances process efficiency by quickly and effectively filtering the ceramic slurry, reducing processing time and minimizing wastage.

Cost-Effective Solution: Vibrating screens are cost-effective and low-maintenance equipment for filtering ceramic slurries, providing a long-term solution for ceramic processing operations.

Consistent Performance: A well-designed ceramic slurry vibrating screen offers consistent and reliable performance, ensuring a smooth and continuous operation in ceramic manufacturing processes.

Applications of Ceramic Slurry Vibrating Screens

Ceramics Industry: Used in the production of ceramic tiles, pottery, porcelain, and other ceramic products that require precise particle size control.

Mining Industry: Used in mineral processing operations for separating and classifying ceramic particles in slurries during ore beneficiation processes.

Chemical Industry: Utilized in chemical processing plants for filtering and separating ceramic slurries in various chemical applications.

Ceramic slurry vibrating screen is a specialized equipment designed for filtering and separating ceramic particles in slurries. Its efficient operation ensures the removal of impurities, oversize particles, and the attainment of a uniform particle size distribution, contributing to the production of high-quality ceramic products in various industrial applications.

-

Granules, powders, and paddle materials can be used

-

Can sieve ultra-fine powder down to 20 microns without clogging the sieve holes

-

Ultrasonic vibrating screen for sea buckthorn fruit powder

Sea buckthorn powder is a valuable ingredient rich in nutrients, and ultrasonic vibrating screen plays a vital role in processing and refining this powder.....

-

Coconut shell charcoal vibrating screen

-

Aluminum Oxide Vibrating Screen

Aluminum oxide vibrating screen is a device used to screen and grade aluminum oxide powder. It separates and screens aluminum oxide powder by placing aluminum oxide powder on the screen and vibrating it ...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials, easy agglomeration....

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.