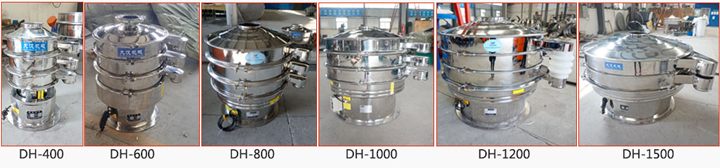

Coconut shell charcoal vibrating screen

Coconut shell charcoal vibrating screen is used in the production and processing of coconut shell charcoal. Coconut shell charcoal is a common biomass charcoal material, usually used to make activated carbon, carbon black and other products. Coconut shell charcoal vibrating screen separates and screens coconut shell charcoal through vibration force.

Working principle of coconut shell charcoal vibrating screen

The working principle of coconut shell charcoal vibrating screen is to start the vibration device (motor or vibrator) to generate vibration force and transmit it to the screen box or screen, so that the coconut shell charcoal vibrates on the screen, thereby achieving screening and grading. By adjusting the vibration parameters and the mesh aperture, the coconut shell charcoal particles can be finely graded and the integrity of the particles can be protected.

Advantages of coconut shell charcoal vibrating screen

High-speed screening: The coconut shell charcoal vibrating screen adopts vibration screening technology, which can effectively screen coconut shell charcoal particles and improve production efficiency.

Fine grading: By adjusting the vibration parameters and the mesh aperture, the coconut shell charcoal particles can be finely graded to meet the requirements of different particle sizes.

Protect the integrity of particles: The vibrating screen uses vibration to screen, which prevents the particles from being squeezed and worn, and is conducive to protecting the integrity of the particles and ensuring product quality.

Easy to operate: The coconut shell charcoal vibrating screen is simple to operate, easy to control and maintain, suitable for industrial production sites, and improves production efficiency.

Low energy consumption and low noise: The coconut shell charcoal vibrating screen usually uses a motor as a vibration source, which has low energy consumption and generates less noise during operation, which is conducive to the quiet requirements of the working environment1.

Application scenarios of coconut shell charcoal vibrating screen include

Coconut shell charcoal screening: Used for screening and grading of coconut shell charcoal to improve the quality and purity of coconut shell charcoal1.

Activated carbon production: In the process of activated carbon production, coconut shell charcoal is screened and graded to obtain particle sizes that meet the requirements.

Coconut shell charcoal energy utilization: In the process of coconut shell charcoal energy utilization, coconut shell charcoal is screened and graded to improve combustion efficiency and energy utilization effect.

Applicable to a variety of processes: Applicable to the screening process in different process flows, and can be used in conjunction with other equipment to form a complete production line.

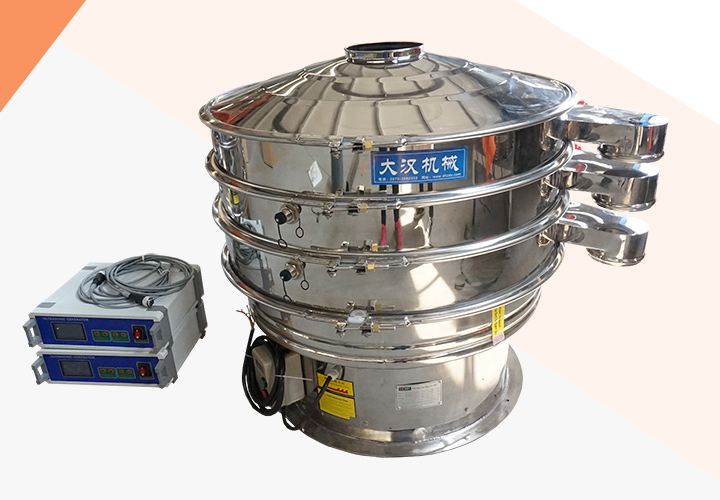

Coconut shell charcoal vibrating screen mainly consists of the following parts

Vibration drive device: Usually composed of a motor, a vibrator or a vibration source, generating vibration force to transmit to the screen box or screen of the screen machine.

Screen box or screening chamber: Working space, usually made of metal material, with suitable size and structure.

Screen mesh: The key part, usually made of metal mesh or polymer mesh, the aperture size is selected as needed1.

Discharge port and collector: Used to collect coconut shell charcoal of different sizes, and achieve separation of different sizes by adjusting the vibration force and the screen mesh aperture.

Coconut shell charcoal vibrating screen is a valuable tool for effectively separating and grading coconut shell charcoal particles in the charcoal production industry. Understanding its working principle, structure, advantages, application and maintenance requirements can help charcoal manufacturers effectively use the equipment to improve product quality and production efficiency.

-

Granules, powders, and paddle materials can be used

-

Can sieve ultra-fine powder down to 20 microns without clogging the sieve holes

-

Aluminum Oxide Vibrating Screen

Aluminum oxide vibrating screen is a device used to screen and grade aluminum oxide powder. It separates and screens aluminum oxide powder by placing aluminum oxide powder on the screen and vibrating it ...

-

Centrifugal screening machine

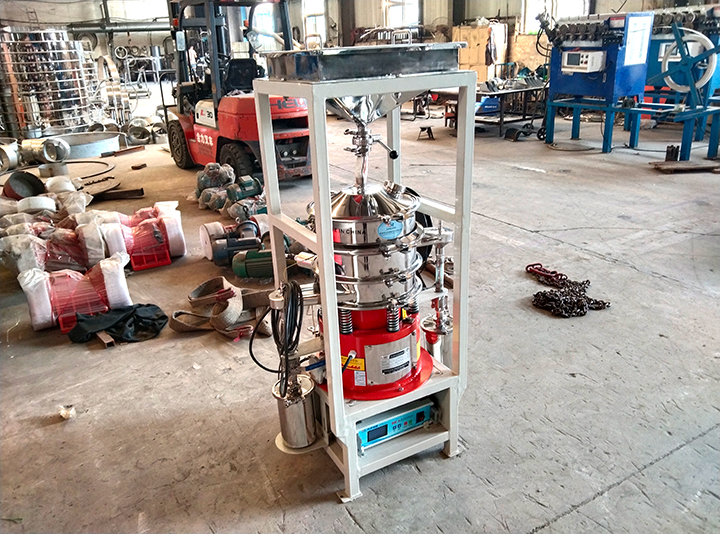

Centrifugal screening machine is designed and produced for screening problems such as light materials, easy agglomeration....

-

Konjac fine powder ultrasonic vibrating screen

Konjac fine powder ultrasonic vibrating screen is a high-precision fine particle screening equipment. The equipment uses the up and down excitation force....

-

Paint raw materials sieve with vibro shaker

Paint raw materials sieve with vibro shaker The quality and performance of paint largely depend on the selection and screening of raw materials.....

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.