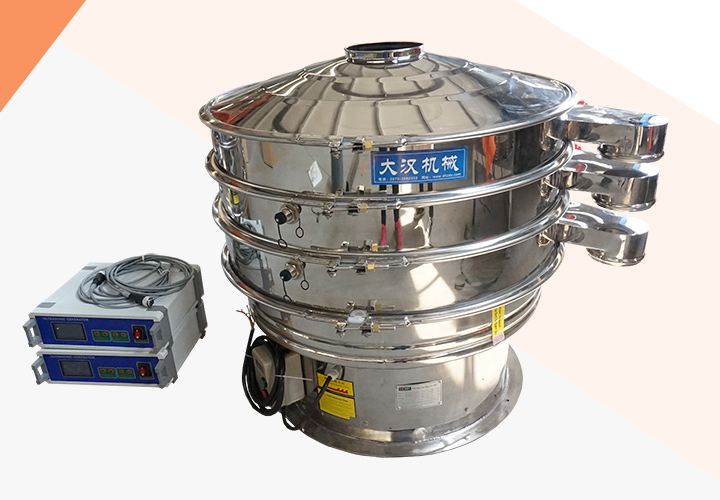

Plastic granule vibration screening machine

Plastic granule vibration screening machine is a device used to screen plastic granules. It mainly achieves material classification and impurity removal by vibration. Its working principle is to make the screen surface resonate through the vibration generated by the vibration motor, thereby driving the material on the screen to jump and roll. Large particles will move forward along the screen surface due to their large inertia and be discharged from the discharge port; while small particles will fall into the lower layer through the pores of the screen, thereby achieving the separation of materials of different particle sizes.

Plastic granule vibration screening machine Function and Importance

Particle Size Classification: The primary function of the plastic granule vibration screening machine is to classify plastic granules according to their particle size. This is essential for ensuring consistency in the quality of the final plastic products.

Quality Control: By removing oversized or undersized particles, the machine helps maintain the desired quality standards of plastic granules, which is crucial for the performance and appearance of plastic products.

Efficiency: The machine improves production efficiency by automating the process of separating and grading plastic granules, reducing manual labor and increasing throughput.

Material Recovery: In recycling operations, the machine helps in separating different sizes of plastic granules for efficient material recovery and reuse.

Plastic granule vibration screening machine Working Principle

The plastic granule vibration screening machine operates on the principle of vibrating screens or sieves, which use vibration to separate particles based on size. Here is an overview of the working principle:

Vibration: The machine consists of a vibrating screen deck with multiple layers of screens or mesh. Vibrating motors generate high-frequency vibrations, causing the plastic granules to move along the screen surface.

Screening: As the plastic granules move across the vibrating screen, particles of different sizes pass through the mesh openings, with oversized particles being separated from the desired size granules.

Separation: The machine typically has multiple decks with different mesh sizes to separate plastic granules into various size fractions. Each deck is designed to capture specific particle sizes.

Collection: The separated plastic granules are collected in different outlets or containers based on their size classification, ready for further processing or packaging.

Advantages of a Plastic Granule Vibration Screening Machine

High Accuracy: The machine provides accurate and precise separation of plastic granules based on size, ensuring uniformity in the final product.

Versatility: It can handle a wide range of plastic granule sizes and types, making it suitable for various applications in the plastic industry.

Efficiency: The vibrating screening machine operates at high speeds, resulting in efficient separation and classification of plastic granules, thereby increasing productivity.

Easy Maintenance: Most machines are designed for easy cleaning and maintenance, ensuring smooth operation and prolonging the machine's lifespan.

Applications of Plastic Granule Vibration Screening Machine

Plastic Manufacturing: Used in plastic production plants to classify and separate plastic granules before molding, extrusion, or other processing steps.

Recycling Industry: Essential for separating and grading plastic granules in recycling facilities to recover and reuse plastic materials efficiently.

Packaging Industry: Helps in screening plastic granules used in packaging materials to ensure uniformity and quality in the production process.

Chemical Industry: Used for screening plastic granules in the production of chemical compounds, ensuring consistent product quality.

Plastic granule vibration screening machine is a critical piece of equipment in the plastic industry for separating and classifying plastic granules based on size. By ensuring the uniformity and quality of plastic granules, the machine plays a vital role in enhancing production efficiency, maintaining quality standards, and supporting various applications in the plastic manufacturing and recycling sectors.

-

Granules, powders, and paddle materials can be used

-

Can sieve ultra-fine powder down to 20 microns without clogging the sieve holes

-

Ceramic slurry vibrating screen

Ceramic slurry vibrating screen is a specialized type of vibrating screen designed for filtering and separating ceramic slurries in industrial processes. ...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials, easy agglomeration....

-

Ultrasonic vibrating screen for sea buckthorn fruit powder

Sea buckthorn powder is a valuable ingredient rich in nutrients, and ultrasonic vibrating screen plays a vital role in processing and refining this powder.....

-

Coconut shell charcoal vibrating screen

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.