Chemical catalyst vibrating screen

Chemical catalyst vibrating screen is a device specially used for screening and grading chemical catalyst particles. Through vibration, catalyst particles of different particle sizes are separated to ensure the efficiency of catalytic reaction and product quality. In chemical production, catalysts are substances that play a vital role and are used to promote chemical reactions or increase reaction rates. Catalyst screening is an essential part of chemical production to ensure that the quality and particle size of the catalyst meet production requirements.

video of chemical catalyst vibrating srcreen

Chemical catalyst vibrating screen

What is the principle of chemical catalyst vibrating screen?

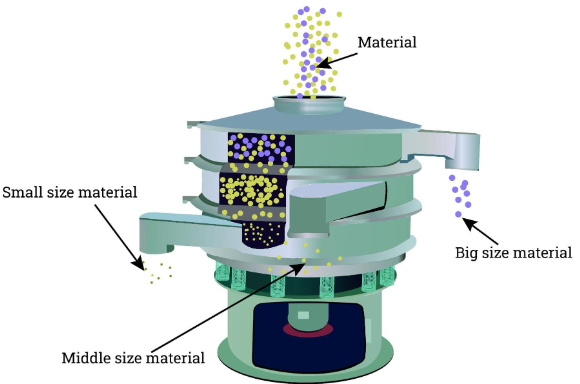

1. Vibration excitation: The core lies in the vibration motor. The motor generates excitation force through the eccentric block and transmits it to the screen box.

2. Screen surface movement: The screen box generates horizontal reciprocating motion or three-dimensional motion under the action of the excitation force.

3. Material movement: The material is subjected to the combined action of the excitation force and gravity on the screen surface, resulting in jumping motion. Particles smaller than the sieve hole pass through the screen, while particles larger than the sieve hole are retained on the screen surface.

4. Screening separation: Catalyst particles of different particle sizes are effectively separated to achieve particle size classification.

What are the advantages of chemical catalyst vibrating screen?

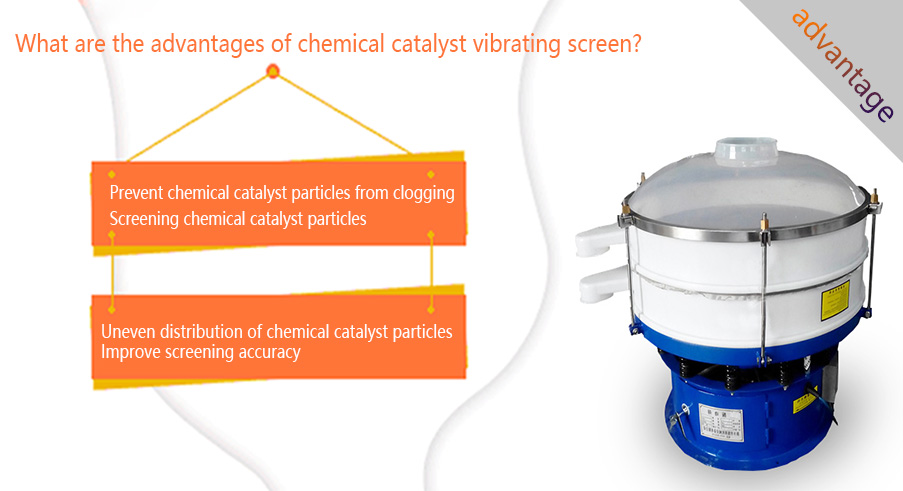

Prevent chemical catalyst particles from clogging: The chemical catalyst vibrating screen can effectively prevent chemical catalyst particles from accumulating and clogging on the screen through vibration, and maintain the screening effect. Clean the screen and screen box regularly to remove particles and debris accumulated on it to prevent clogging.

Screening chemical catalyst particles: During the catalyst production process, the chemical catalyst vibrating screen can be used to screen catalyst particles, remove fine particles and impurities in the particles, ensure that the particles are uniform in size, and improve the activity and stability of the catalyst.

Uneven distribution of chemical catalyst particles: The vibration of the chemical catalyst vibrating screen can make the particles well dispersed during the screening process, which helps to improve the particle size distribution of chemical catalyst particles. Adjust the amplitude and vibration frequency of the vibrator to obtain a good screening effect and chemical catalyst particle distribution.

Improve screening accuracy: By setting up multiple layers of screens, multi-level screening can be achieved to improve screening accuracy. The chemical catalyst vibrating screen further improves screening accuracy through ultrasonic vibration.

Application of chemical catalyst vibrating screen

1. Chemical catalyst production: used to screen raw materials, ensure that the particle size meets the requirements, and improve the quality of chemical catalysts. After production is completed, the chemical catalyst vibrating screen grades the finished chemical catalysts and separates products of different particle sizes to meet different needs. It can remove impurities in raw materials or finished products to ensure the purity of chemical catalysts.

2. Use of chemical catalysts: Before loading the reactor with catalysts, the chemical catalyst vibrating screen is used for screening, removing broken particles and dust, ensuring uniform loading and improving reaction efficiency. When replacing chemical catalysts, the chemical catalyst vibrating screen can separate the still usable parts, reducing waste and reducing costs.

3. Chemical catalyst recycling: When recycling waste chemical catalysts, the chemical catalyst vibrating screen is used to separate the incompletely deactivated parts for recycling. For waste chemical catalysts containing precious metals, the chemical catalyst vibrating screen can separate the metal components for subsequent recycling.

4. Other applications: The chemical catalyst vibrating screen is used to detect the particle size distribution of catalysts to ensure stable product quality. It is used to screen raw materials to ensure that the particle size meets the requirements and improve the quality of catalysts. After production is completed, the vibrating screen will grade the finished catalyst and separate products of different particle sizes to meet different needs. The vibrating screen can remove impurities in raw materials or finished products to ensure the purity of the catalyst.

How to fix a chemical catalyst vibrating screen?

Fault diagnosis: First, the chemical catalyst vibrating screen needs to be fully inspected and fault diagnosed to find out the problem and determine the parts or systems that need to be repaired.

Safety measures: Before any maintenance or repair work, always cut off the power supply of the equipment and ensure that the equipment is in a safe state. Ensure that the operator wears appropriate personal protective equipment, such as gloves, goggles, etc.

Disassembly and replacement of damaged parts: According to the fault diagnosis results, disassemble the parts or systems that need to be repaired. Carefully inspect the damaged parts to determine whether they need to be repaired or replaced. When replacing damaged parts, make sure to select suitable replacement parts and follow the equipment manual or professional advice.

Lubrication and adjustment: After replacing parts, ensure proper lubrication and adjustment to ensure the normal operation of the equipment. Adjust the amplitude and vibration frequency of the vibrator to meet the requirements of the equipment.

Assembly and testing: After replacing parts and adjustments, reassemble the equipment. Before restarting the equipment, perform necessary functional tests to ensure that the repair work is completed and the equipment is operating normally.

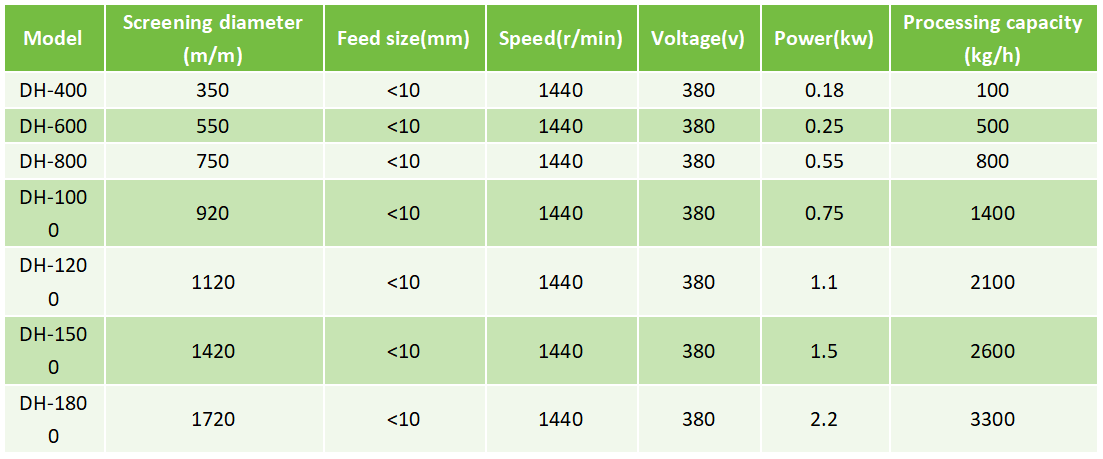

Specifications of Chemical Catalyst Vibrating Screen

How do you maintain a chemical catalyst vibrating screen?

1. Regular cleaning and maintenance: Clean the screen and screen box regularly to remove the catalyst particles and debris accumulated on it to ensure the screening effect. Check the vibrator and transmission parts to ensure their normal operation and remove the accumulated dust and debris in time.

2. Lubrication maintenance: Check the lubrication of the vibrating screen regularly to ensure that each bearing and transmission part is adequately lubricated. According to the use of the equipment, regularly replace the lubricating oil or grease to keep the equipment running normally.

3. Inspection and adjustment: Regularly check whether the various parts of the vibrating screen are loose or worn. If there is a problem, adjust or replace it in time. Regularly check whether the amplitude and vibration frequency of the vibrator meet the requirements and adjust them as needed.

4. Prevent blockage and damage: Avoid excessive particle materials or foreign matter from entering the screen box to avoid blockage or damage to the screen. Pay attention to the working environment of the catalyst vibrating screen to avoid being affected by moisture, corrosion and other factors to extend the service life of the equipment.

Who is the manufacturer of chemical catalyst vibrating screens?

Dahan manufacturers provide ultrasonic rotary vibrating screen, built-in ultrasonic rotary vibrating screen, external ultrasonic rotary vibrating screen, pharmaceutical ultrasonic rotary vibrating screen, powder ultrasonic rotary vibrating screen, starch ultrasonic rotary vibrating screen, coating ultrasonic rotary vibrating screen, explosion-proof ultrasonic rotary vibrating screen, stainless steel ultrasonic rotary vibrating screen and other products. In addition, it can also be specially customized according to user needs.

The maintenance of Chemical catalyst vibrating screens is of great significance to ensure the normal operation of the equipment, improve the screening efficiency and extend the service life of the equipment. Through regular inspection, maintenance and maintenance, the occurrence of failures can be effectively avoided and production efficiency can be improved.

-

High-precision screening of materials is achieved through a unique screening method

-

Fully sealed structure, no powder overflow, no liquid overflow

-

Remove lumps and debris in flour, improve flour quality

-

Plastic sheet vibrating screen

Plastic sheet vibrating screen is a kind of equipment specially used for screening plastic...

-

Soy product vibrating screen

Detergent vibrating screen is a screening device commonly used in washing powder production...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Standard test sieve

Standard test sieves are precision mesh screens used to separate particles based on size in various industries ...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.