Standard test sieve

![[field:title/]](/uploads/241028/1-24102Q000541M.jpg)

Callback

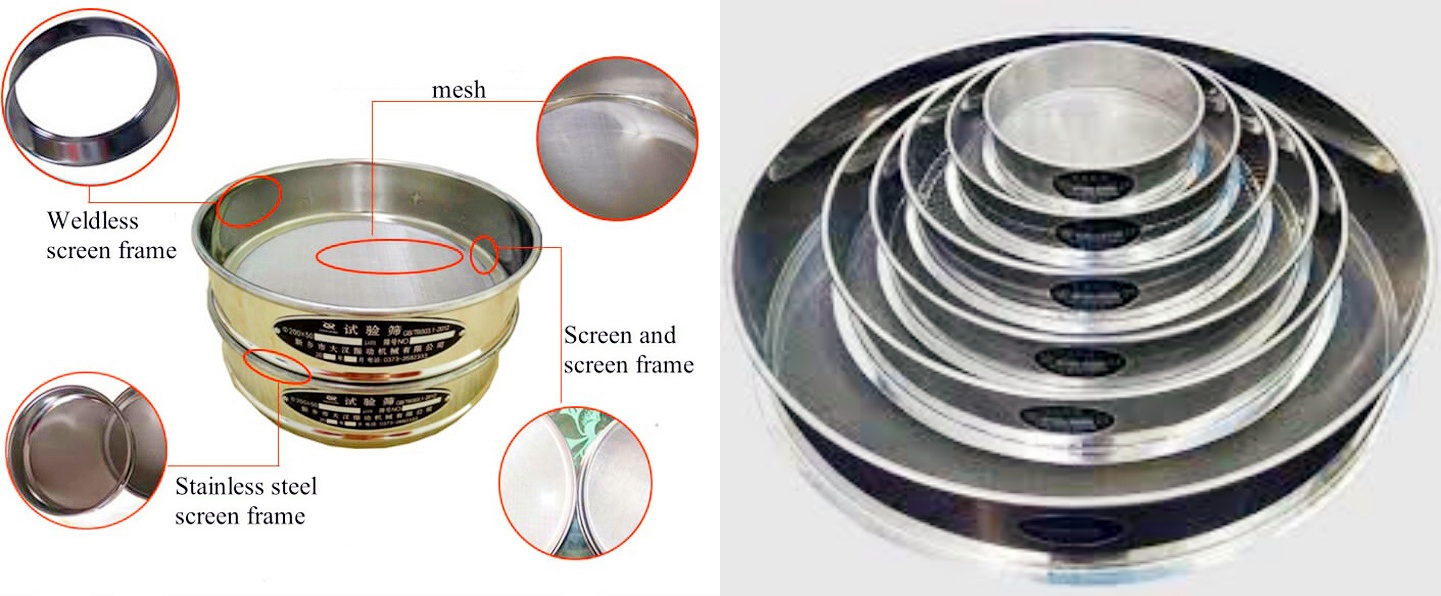

| Aperture sizes: 0.02-2.36mm | Material:Stainless steel304/Brass/Chromeplate |

Frame diameter::500/400/300/200/120/80/75mm, or others as your requirements.

Surface type: Woven Wire Mesh/Perforated Plate/Electroforming Mesh

Standard test sieve is a precision tool for particle size analysis and classification of granular materials, used to screen and separate materials of different particle sizes. It is mainly used in laboratories to perform standard inspections, screening, filtering, and testing on the particle size structure, liquid solid content, and impurity content of granular and powdery materials. It can automatically stop and can accurately separate 2 to 7 particle segments of granular materials at the same time.

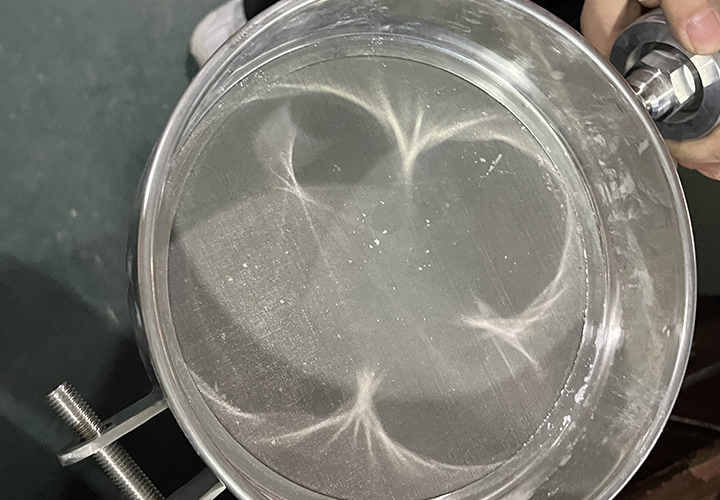

The structure of standard test sieve

Screen frame: generally made of stainless steel, brass or other corrosion-resistant materials to ensure screening accuracy and durability.

Screen: made of wire mesh or perforated plate, the aperture is strictly in accordance with international or national standards such as ISO, GB, ASTM, JIS, etc.

Screen cover and screen bottom: used to seal and collect screened materials to prevent sample loss.

How does the standard test sieve work?

The working principle of the standard test sieve is based on the principle of vibration screening. The test sieve is usually composed of a sieve frame, a screen, a vibration mechanism and a support structure. When the test sieve is started, the vibration force generated by the vibration mechanism is transmitted to the sieve frame, causing the sieve frame and the screen to vibrate. After the particles are put into the sieve frame, they are affected by the vibration force and jump on the screen. Small particles fall into the container below through the sieve holes, while large particles remain on the surface of the screen. Through screens of different specifications, particles of different sizes can be separated and classified. Particles are separated during vibration, and the screening effect is affected by parameters such as amplitude and frequency. After screening, particle size analysis can be performed based on particle distribution to provide data support for production process optimization and product quality control.

Features of standard test sieve

1. Accurate screening, can screen 0.025~3mm;

2. Small size, light weight, easy to move;

3. Platform operation, no need to fix;

4. Automatic shutdown can be scheduled to ensure experimental repeatability;

5. Sturdy appearance, wear-resistant, and high temperature resistant.

How many types of mesh are there for standard test sieves?

Standard test sieve mesh type 1: wire woven mesh

The most widely used mesh - square holes from 2.36mm to 0.02mm

Wire mesh screen: aperture range 0.02-2.36mm, good flexibility, suitable for most powder screening.

Wire woven mesh has low cost and good flexibility, but relatively high precision (large mesh is allowed), and the mesh may be deformed. The mesh precision can be controlled by expanding and shrinking the holes, and the holes can be fixed by electrochemical methods. Generally, manufacturers with high-precision mesh production capabilities are required to ensure mass production. The most widely used industry is the diamond industry, especially export manufacturers require a standard negative difference, because the foreign surplus is half a size different from that of China, and the basic particles account for more than 90%.

Standard test sieve mesh type 2: perforated plate mesh

Mainly used for large meshes - round and square holes from 0.2mm to several hundred mm

Perforated plate screen: aperture 0.2mm to hundreds of millimeters, strong impact resistance, mostly used for large particle materials (such as sand, gravel, coal samples).

Perforated plate mesh refers to a mesh that uses a punch press to punch out the target pattern in the plate to be processed. The materials include stainless steel, aluminum plate, hot and cold steel plate, copper plate, PVC plate film, etc. The mesh precision of the perforated plate mesh is uniform and not easy to deform. It is mainly used for the detection of large particles. The hole types include long holes, round holes, square holes, triangular holes, fish scale holes, bridge holes, diamond holes, pentagonal holes, hexagonal holes, eight-shaped holes, cross holes, nail holes, plum blossom holes, herringbone holes, I-shaped holes and other special-shaped holes.

Standard test sieve mesh type 3: electroforming mesh

Mainly used for high-precision screening - each mesh can be within the average error range

Electroformed thin plate screen: accuracy can reach 1 micron, used for high-precision analysis of ultrafine powders (such as nanomaterials).

Electroforming mesh is manufactured by electrochemical method, with the highest precision. Theoretically, the precision can reach one micron. The characteristic is that the mesh of the rigid structure will not deform. The particle size distribution of electroforming filter materials is significantly narrowed. Compared with woven wire mesh filter materials, it requires cleaner and less maintenance, allowing longer filtration time and service life to greatly improve production efficiency. It has a wide range of applications in high-precision laboratory particle size detection scenarios.

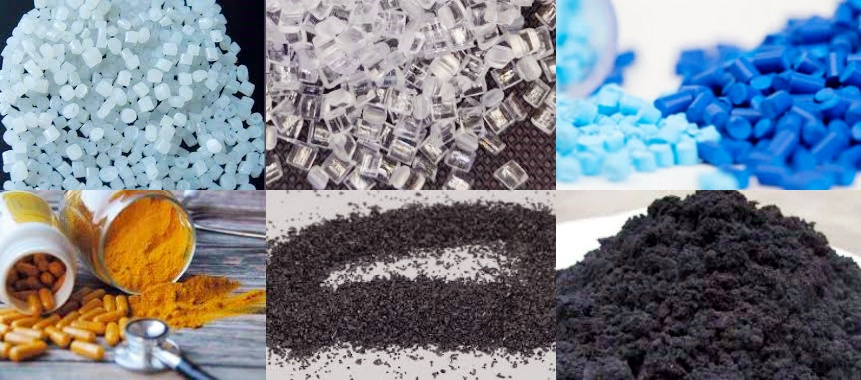

Scope of application of standard test sieves

①Particle size analysis of granular materials: used to determine the particle size distribution of powder or granular materials, such as sand, ore, metal powder, etc.

②Quality inspection of powder materials: such as fineness inspection of cement, flour, medicinal powder, etc., to ensure that the product meets the quality standards.

③Screening experiment: used for research laboratories and quality inspection agencies to study and test the particle size classification of materials.

Recommended table of standard test sieve mesh numbers

|

Mesh number (Mesh) |

sieve hole diameter (mm) |

sieve hole diameter (μm) |

applicable fields |

|

5 |

4.000 |

4000 |

sand, ore, coarse granular materials |

|

10 |

2.000 |

2000 |

sand, chemical granules, coarse grains |

|

20 |

0.850 |

850 |

granular fertilizer, plastic granules |

|

40 |

0.425 |

425 |

cement, flour, medicinal powder coarse sieve |

|

60 |

0.250 |

250 |

fine chemical powder, Pesticide powder |

|

80 |

0.180 |

180 |

graphite powder, pigment powder |

|

100 |

0.150 |

150 |

ceramic powder, food additives |

|

120 |

0.125 |

125 |

metallurgical powder, mineral powder |

|

200 |

0.075 |

75 |

fine chemicals, pharmaceutical powder |

|

300 |

0.050 |

50 |

ultrafine powder, carbon powder |

|

400 |

0.038 |

38 |

nanomaterials, catalysts |

|

500 |

0.025 |

25 |

ultrafine chemicals, pharmaceutical powder |

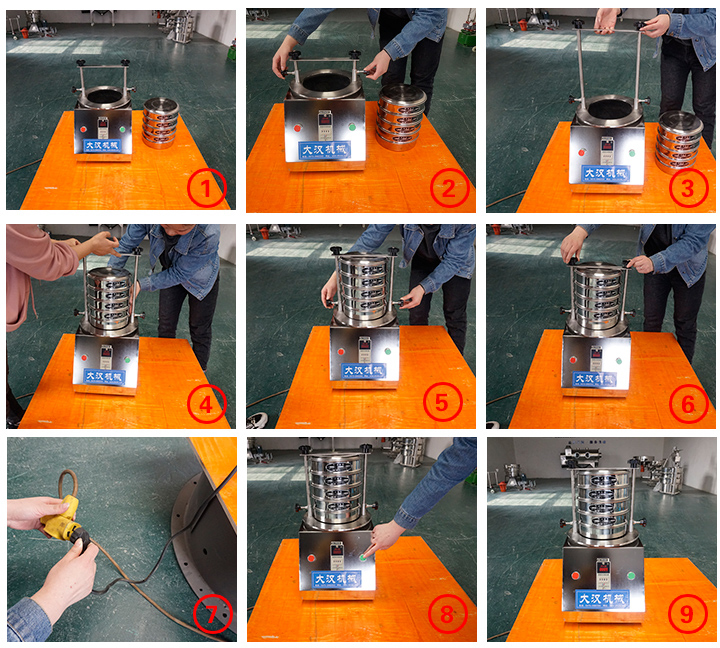

How to use standard test sieve?

Standard test sieves are widely used in scientific research and production departments, laboratories, and quality inspection rooms in metallurgy, chemical industry, medicine, building materials, geology, national defense and other industries. They are used for vibration screening, filtration, and standard test detection of particle size structure, liquid solid content, and impurity content of granular and powdery materials.

-

The vibration is uniform, and the excess powder on the surface of the material can be shaken to remove the excess powder.

-

Used to safely screen cocoa powder to remove impurities such as large particles, helping to ensure its quality and consistency

-

Screening black soldier fly feces and larvae can separate the worms and feces, saving labor

-

Fully sealed structure, no powder overflow, no liquid overflow.

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials, easy agglomeration....

-

Silicon powder for test sieve

Silicon powder for test sieve is a fine powder composed of silicon particles that are commonly used in various industrial applications, including electronics, metallurgy, and materi ....

-

Paint raw materials sieve with vibro shaker

Paint raw materials sieve with vibro shaker The quality and performance of paint largely depend on the selection and screening of raw materials.....

-

Dietary Supplements for Vibrating Sieve

Dietary supplements vibrating sieve As an efficient and reliable sieving equipment, it plays an important role in the production of dietary supplements. Through high-frequency vibra ...

-

Aqua Feed For Ultrasonic Vibrating Screen

The aquatic feed ultrasonic vibrating screen uses advanced ultrasonic technology to achieve an efficient screening process through high-frequency weak vibration. Compared with tradi ...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.