Foam particle straight screen

Foam particle straight screen is a special device for screening foam particles. It is mainly used to classify foam particles of different particle sizes or remove impurities. It is usually suitable for screening materials such as foam plastics, EPS (expandable polystyrene), EPE (polyethylene foam), etc. It uses a special screen structure and vibration method to efficiently separate solid particles, liquids and gases in the foam.

Video of the foam particle straight screen

How does the foam particle straight screen work?

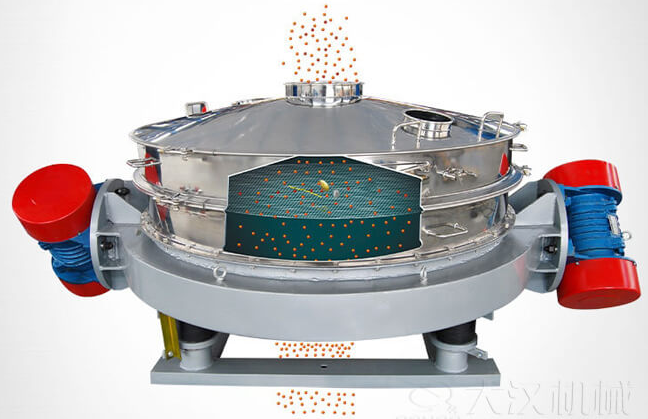

Vibration is generated by a vibration motor or ultrasonic vibrator, and the material moves on the screen based on the screening effect of the screen and the inertial force generated by the vibration. The material enters the screen box through the feed port, and is subjected to the vibration in the screen box, causing the foam to break, the solid particles to be trapped by the screen, and the liquid and gas to be discharged through the screen. Smaller particles pass through the screen and fall into the lower layer, while larger particles move forward along the surface of the screen and are finally discharged from the discharge port.

Structural features of the foam particle straight screen

1. Screen box: The screen box is usually made of stainless steel, which is corrosion-resistant and easy to clean. There are multiple layers of screens in the screen box, and the aperture of each layer of screens is different, which can achieve multi-level screening.

2. Vibration motor: Provides vibration power to make the screen box vibrate, so that the material moves on the screen surface.

3. Screen: The screen material is diverse, and different screen materials can be selected according to the characteristics of the material, such as stainless steel, nylon, etc.

4. Discharge port: There are solid material discharge port, liquid discharge port and gas discharge port respectively.

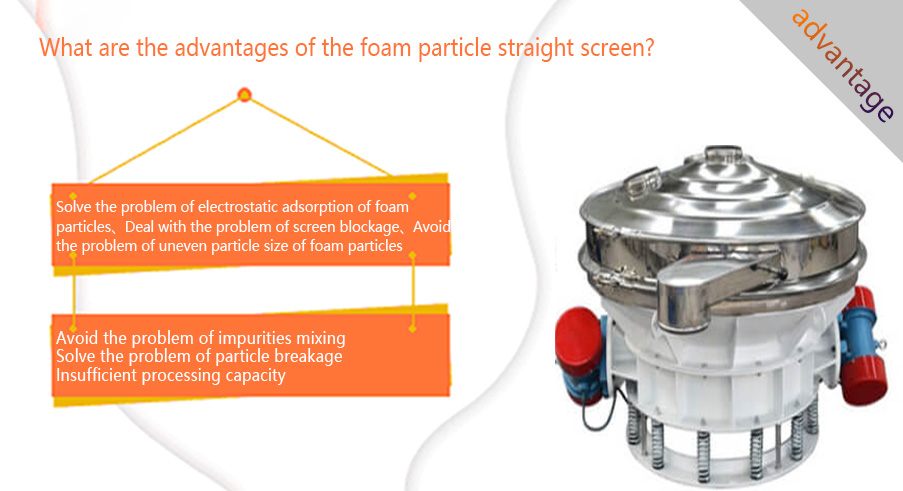

What are the advantages of the foam particle straight screen?

1. Solve the problem of electrostatic adsorption of foam particles: Foam particles are prone to generate static electricity during the screening process, causing the particles to be adsorbed on the screen or the inner wall of the equipment, affecting the screening efficiency. The high-frequency vibration of the ultrasonic vibrator destroys the electrostatic adsorption force between the particles and the screen, allowing the particles to pass through the screen smoothly.

2. Deal with the problem of screen blockage: Foam particles are irregular in shape and are easily stuck in the screen holes, causing the screen to be blocked, affecting the screening efficiency. The high-frequency vibration of the foam particle straight screen can effectively prevent the particles from getting stuck in the screen holes and keep the screen unobstructed.

3. Avoid the problem of uneven particle size of foam particles: The particle size distribution of foam particles is uneven, which may lead to unsatisfactory screening effect. By adjusting the frequency and amplitude of the vibration motor, it can adapt to the screening needs of different particle sizes. Configure a multi-layer screen to divide the particles into multiple grades according to the particle size to ensure the screening accuracy.

4. Avoid the problem of impurities mixing: Dust, metal fragments, agglomerates and other impurities may be mixed into the foam particles, affecting the product quality. Use a coarse screen to remove large particle impurities and a fine screen to remove small particle impurities. Install a magnetic separation device at the feed port or during the screening process to remove metal impurities.

5. Solve the problem of particle breakage: During the screening process, foam particles may be broken due to vibration or collision, affecting product quality. Use low-amplitude, high-frequency vibration to reduce the impact on particles. Install a buffer device inside the equipment to reduce collisions between particles.

6. Insufficient processing capacity: Traditional screening equipment has limited processing capacity and cannot meet the needs of large-scale production. Use high-power vibration motors to improve screening efficiency, and choose a large-size screen to increase the single processing capacity. The equipment supports continuous feeding and discharging to meet the needs of large-scale production.

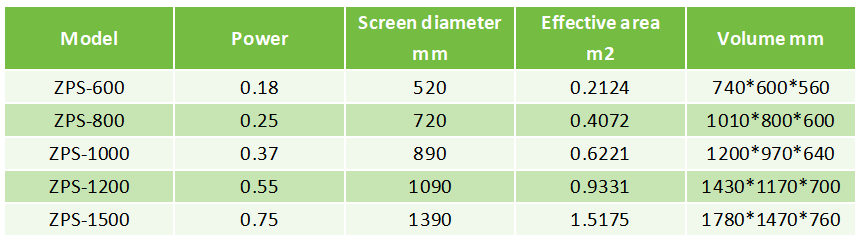

Technical parameters of foam particle screen

Application of Foam Particle Straight Screen

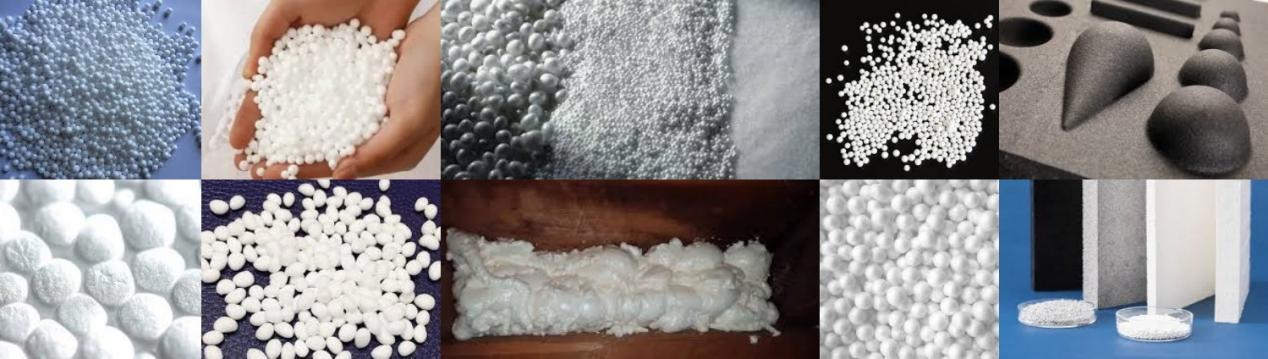

1. Foam plastic production industry: Foam particles need to be screened to ensure uniform particle size to meet the requirements of subsequent molding or foaming process. The foam particle straight screen screens out particles that are too large or too small to ensure the consistency of particle size, remove impurities or agglomerated particles generated during the production process, and improve product quality. It can also be used to recycle waste materials and re-screen unqualified particles for reuse.

2. Packaging material industry: The particle size of foam particles directly affects the performance and appearance of the material. The foam particle straight screen is used to screen foam particles of different particle sizes, and can also be used to manufacture packaging materials of different densities and strengths, remove impurities, and ensure the cleanliness and safety of packaging materials.

3. Building insulation industry: Foam particles are often used as fillers or additives for building insulation materials. The foam particle straight screen is used to screen particles to meet the density and insulation performance requirements of building materials, and can also be used to remove impurities to ensure the quality and construction effect of insulation materials.

4. Toy and craft manufacturing: Foam particles are often used to fill toys or make crafts. The foam particle straight screen is used to screen the particles to ensure the uniformity and comfort of the filling, remove impurities, and ensure the safety and beauty of toys and crafts.

5. Waste foam recycling industry: The recycling of waste foam is an important part of the environmental protection industry. The foam particle straight screen crushes the waste foam and screens it to separate the reusable particles, improve the purity of the recycled particles, and can also reuse the screened particles for production to reduce resource waste.

6. Automobile and aerospace industry: Foam particles are used to make lightweight materials (such as car interiors, aircraft seat fillings, etc.). The foam particle straight screen screens the particles to meet the strength and weight requirements of lightweight materials. , Ensure the durability and safety of the material.

7. Agriculture and horticulture industry: Foam particles can be used for soil improvement or as a substrate for soilless cultivation. The foam particle straight screen screens the particles to ensure the air permeability and water retention of the substrate to ensure the healthy growth of plants.

8. Medical and sanitation industry: Foam particles are used to make medical dressings and sanitary products. The foam particle screen can screen the particles to ensure the softness and water absorption of the product. Remove impurities to ensure the hygiene and safety of the product.

Foam particle straight screen plays an important role in many industries. Its core function is to achieve particle size control and impurity removal through screening. By choosing a suitable foam particle straight screen, solid particles, liquids and gases in the foam can be effectively separated, production efficiency can be improved, and product quality can be improved.

-

Fully sealed structure, no powder overflow, no liquid overflow

-

Remove lumps and debris in flour, improve flour quality

-

For safe sieving and precise grading of liquids, powders and granules, suitable for plants and factories that need to handle large volumes of products

-

For separation of different particle sizes in the same product, safe screening to eliminate foreign matter, solid-liquid separation, etc.

-

Chemical catalyst vibrating screen

Chemical catalyst vibrating screen is a device specially used for screening and grading chemical catalyst...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Standard test sieve

Standard test sieves are precision mesh screens used to separate particles based on size in various industries ...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.