Carbon steel straight screen

Carbon steel straight screen is a common screening equipment, usually used in the industrial field to screen and grade granular materials. This screening equipment is made of carbon steel, which is durable and suitable for screening and grading various granular and powder materials. It has a simple structure, large processing capacity and high screening efficiency, and is widely used in chemical, food, medicine, metallurgy and other industries.

Video of carbon steel straight screen

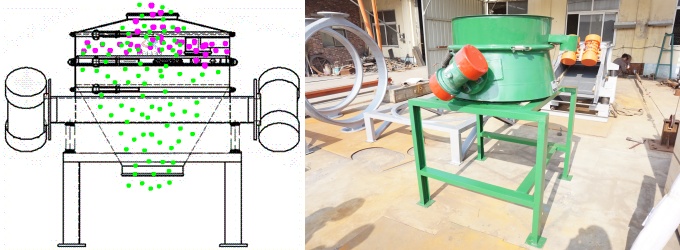

How does the carbon steel straight screen work?

1. Vibration mode: Carbon steel straight screen adopts linear vibration mode, and the material moves linearly on the screen surface. Through the exciting force of the vibration motor, the material is quickly dispersed and moved forward on the screen surface.

2. Screening process: The material enters the screen machine from the feed inlet. Under the action of vibration, fine particles pass through the screen, and coarse particles move along the screen surface and are discharged from the discharge port.

What materials are suitable for carbon steel straight screens?

Carbon steel straight screens are mostly used for coarse and precise screening of powder coatings, veterinary drugs, fertilizer particles, pebbles, polytetrafluoroethylene, fiber cotton, lithium carbonate, lithium fluoride, dyes, stone powder, fertilizer (ammonium sulfide), lime powder, sand, magnesium oxide, plastic additives, slag in cement, polyvinyl alcohol, sodium sulfate, metal powder, chemical raw materials, additives, silicon carbide, zinc oxide powder, feed additives, soda ash, metabisulfate (sodium sulfate) and other materials. It has a large processing capacity and is easy to combine with the production line.

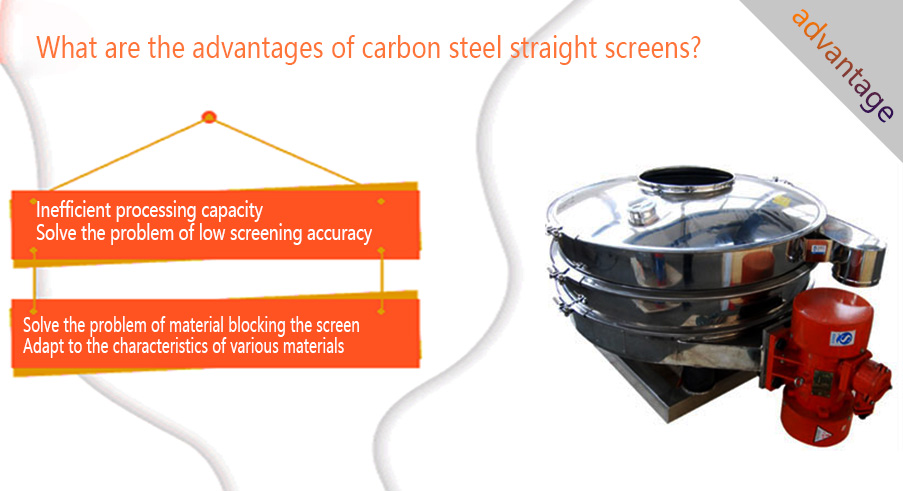

What are the advantages of carbon steel straight screens?

1. Inefficient processing capacity: Traditional screening equipment has a low processing capacity due to the long residence time of materials on the screen surface, which cannot meet the needs of large-scale production. The carbon steel straight-discharge screen adopts a straight-discharge design, and the material is discharged directly, which reduces the residence time on the screen surface, greatly increases the screening output, and meets the needs of large-scale production.

2. Solve the problem of low screening accuracy: the material does not move sufficiently on the screen surface, resulting in incomplete screening and affecting the screening accuracy. The carbon steel straight-discharge screen can control the movement trajectory and speed of the material on the screen surface by adjusting the parameters of the vibration motor, optimize the screening effect, and improve the screening accuracy.

3. Solve the problem of material blocking the screen: fine powder, fiber or sticky substances in the material are easy to block the screen, reducing the screening efficiency. The carbon steel straight-discharge screen can be equipped with bouncing balls, ultrasonic cleaning devices and other screen cleaning devices to effectively clean the blockages on the screen, keep the screen clean, and improve the screening efficiency.

4. Adapt to the characteristics of various materials: multiple layers of screens can be installed to achieve multi-level screening to meet the screening needs of materials of different particle sizes. For materials with high viscosity, anti-sticking screens or screen cleaning devices can be used to prevent material adhesion. For materials with high humidity, vibration parameters can be adjusted or drying devices can be added.

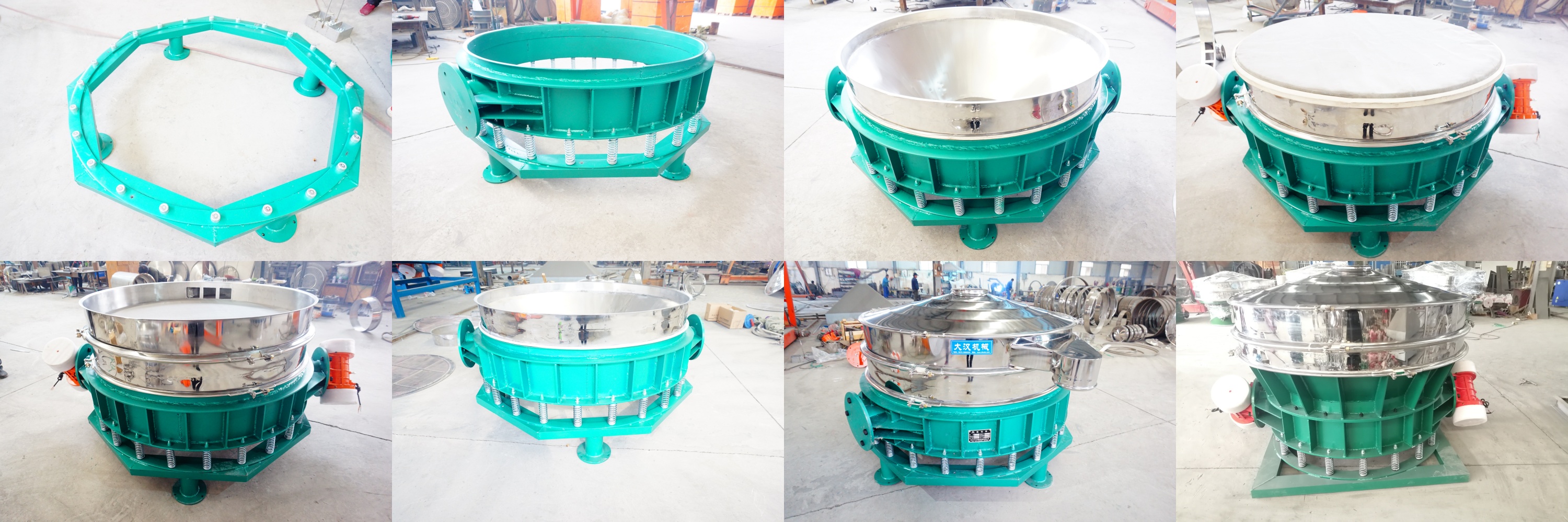

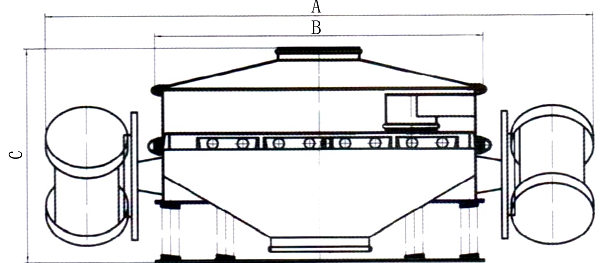

Structure of carbon steel straight screen

Screen frame: Made of carbon steel material, it has high strength and wear resistance. It is used to fix the screen and support the entire screening structure.

Screen: Select screens of different materials (such as stainless steel, nylon) and mesh sizes according to the characteristics of the material. The screen can be installed in a single layer or multiple layers to achieve multi-level screening.

Vibration motor: Provides the vibration force required for screening and drives the screen frame to vibrate linearly.

Base and spring: The base supports the equipment, and the spring is used for shock absorption and stable operation.

Feed port and discharge port: The feed port is located at the top of the screen machine, and the discharge port is distributed on the side and bottom of the screen machine.

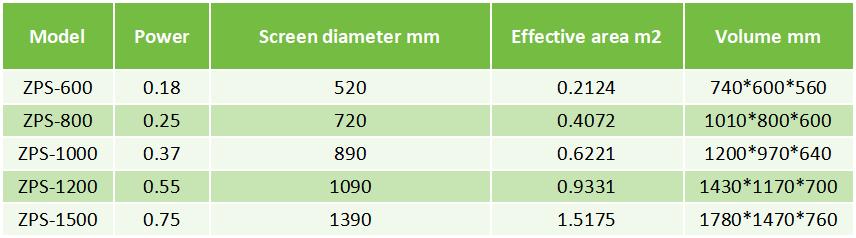

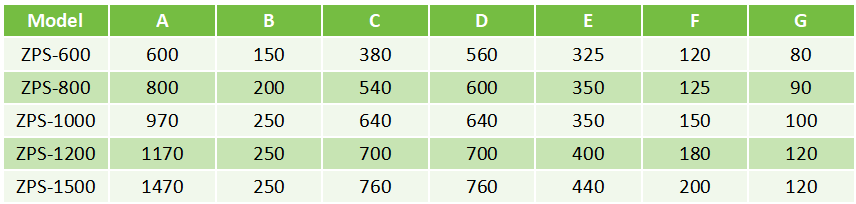

Technical parameters of carbon steel straight screen

What can carbon steel inline screens be used for?

1. Mining: Carbon steel inline screens are often used for screening and grading of coal mines, metal mines, limestone and other ores to help improve the grade of ore and improve production efficiency.

2. Building materials: Carbon steel inline screens can be used for screening and grading of building materials such as cement, sandstone, bricks, etc. to ensure the quality of building materials products.

3. Chemical industry: Carbon steel inline screens are often used for screening and grading of materials such as fertilizers, plastic particles, and chemical raw materials to ensure that the products meet the specifications. Used to screen sticky materials such as resins and pigments, and solve the problem of material adhesion through anti-sticking design and efficient vibration.

4. Metallurgy: Carbon steel inline screens can be used for screening and grading of materials such as iron ore and steelmaking materials to improve the quality of metallurgical products. Used to screen materials with higher hardness such as metal powders and ores, and reduce equipment wear through carbon steel materials and wear-resistant screens.

5. Food processing: Carbon steel inline screens can be used for screening and impurity removal of food raw materials to ensure food safety and quality. Used to screen fine powder materials such as flour and powdered sugar, and improve screening accuracy through multi-layer screens and uniform feeding.

6. Environmental protection: Carbon steel straight screens can be used for screening and grading in environmental protection projects such as sewage treatment and solid waste treatment to achieve resource recovery and reduce environmental pollution.

Size of carbon steel straight screen

Carbon steel straight screen effectively solves the problems of low processing efficiency, screen clogging, low screening accuracy, dust pollution, equipment maintenance, cost control, etc. in the material screening process through its unique in-line design, screen cleaning device, adjustable vibration parameters, sealing device, etc., and achieves efficient, accurate and environmentally friendly screening effects. It is widely used in food, chemical, metallurgy and other industries.

-

Fully sealed structure, no powder overflow, no liquid overflow

-

Remove lumps and debris in flour, improve flour quality

-

For safe sieving and precise grading of liquids, powders and granules, suitable for plants and factories that need to handle large volumes of products

-

For separation of different particle sizes in the same product, safe screening to eliminate foreign matter, solid-liquid separation, etc.

-

Chemical catalyst vibrating screen

Chemical catalyst vibrating screen is a device specially used for screening and grading chemical catalyst...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Standard test sieve

Standard test sieves are precision mesh screens used to separate particles based on size in various industries ...

-

Circular swing screen

Circular swing screen, also known as swing screen or shaking screen, is a low-frequency rotary vibration...

-

Quartz sand vibrating screen

Quartz sand vibrating screen is a screening device specially designed for bulk materials such as...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.