Quartz sand vibrating screen

Quartz sand vibrating screen is a screening device specially designed for bulk materials such as quartz sand. The exciting force of the vibration motor drives the screen body to vibrate at high frequency, so that the quartz sand forms a continuous throwing motion on the screen surface, thereby realizing the screening and grading of materials. The equipment has the advantages of high screening efficiency, large processing capacity, and high screening accuracy. It is widely used in quartz sand processing, building materials, chemical industry and other fields. The quartz sand vibrating screen has a simple structure and is easy to operate. It can be designed as a single layer or multi-layer according to actual needs to meet the screening operations with different particle size requirements.

Video of quartz sand vibrating screen

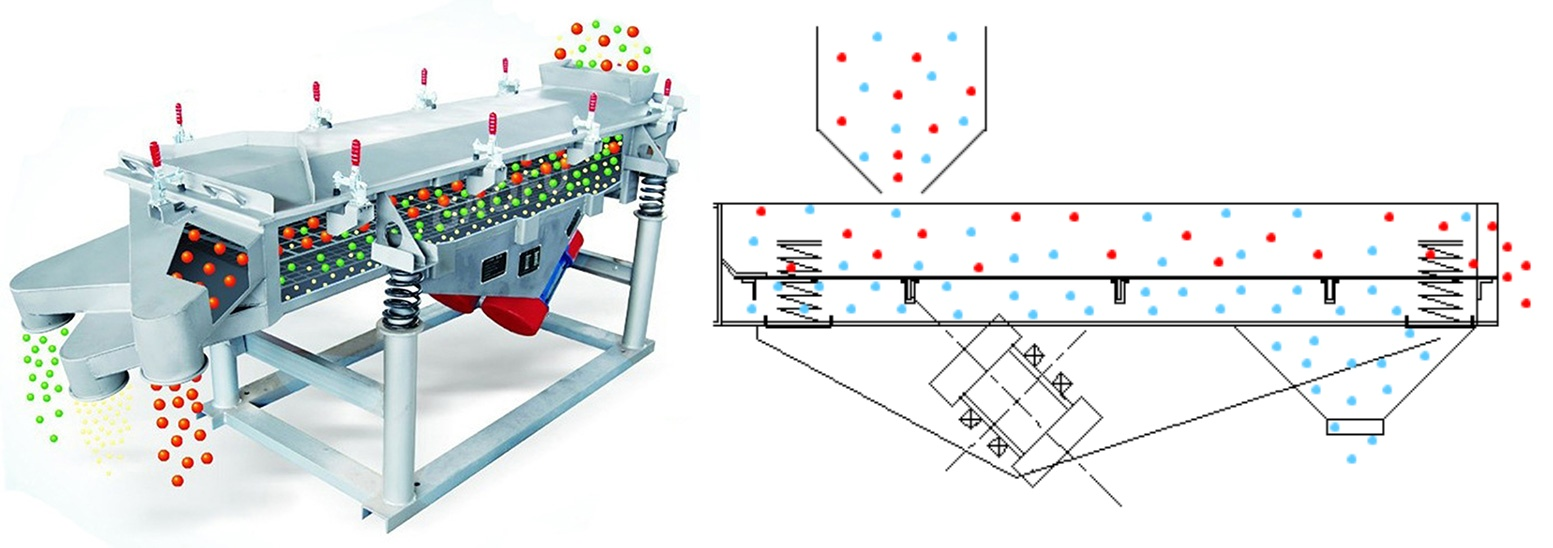

How does the quartz sand vibrating screen work?

Under the action of vibration, the quartz sand particles form a continuous throwing motion on the screen surface, thereby achieving screening and grading. By adjusting the speed and phase angle of the vibration motor, the vibration trajectory and amplitude of the screen surface can be changed to meet the screening requirements of different materials.

The structure of quartz sand vibrating screen

1、Vibration motor: The vibration motor is the power source of the quartz sand vibrating screen. It drives the screen to vibrate and realizes the particle screening process.

2、Screen box and screen: The screen box is the part where the screen is installed. It usually has a rectangular or circular structure, and the internal space is used to place the granular material for screening. The screen is usually made of wire mesh or synthetic fiber mesh with different mesh sizes.

3、Bracket: The bracket is used to support the various components of the vibrating screen to ensure the stability and safety of the equipment.

4、Base: The base supports the entire vibrating screen equipment to ensure the stability and smooth operation of the equipment.

5、Discharge port: The discharge port is used to collect the granular material after screening and output the particles that meet the requirements for subsequent production or processing.

6、Adjustment device: The quartz sand vibrating screen is usually equipped with an adjustment device, which can adjust the size, amplitude and vibration frequency of the vibration force to meet the screening requirements of different granular materials.

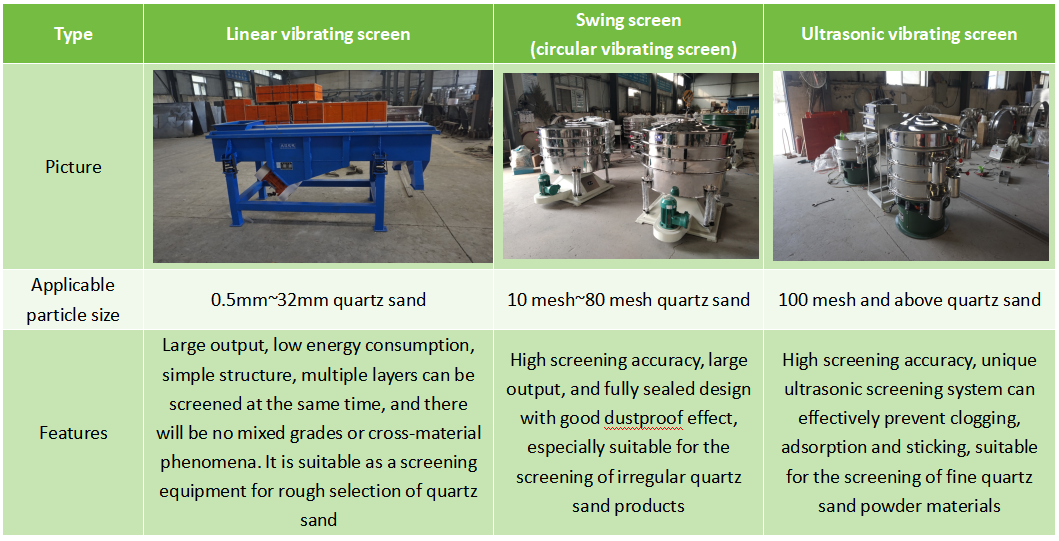

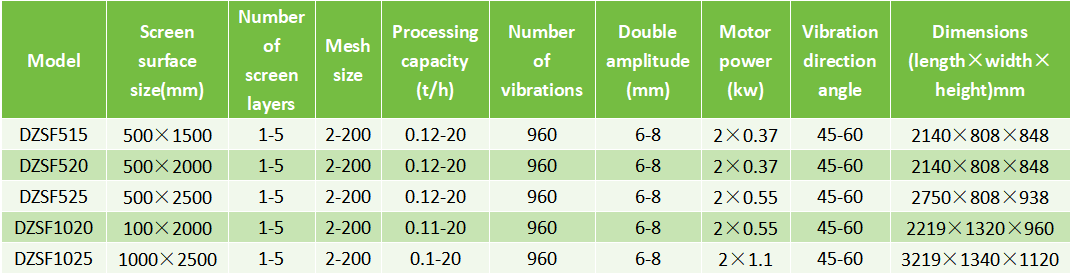

What types of quartz sand vibrating screens are available?

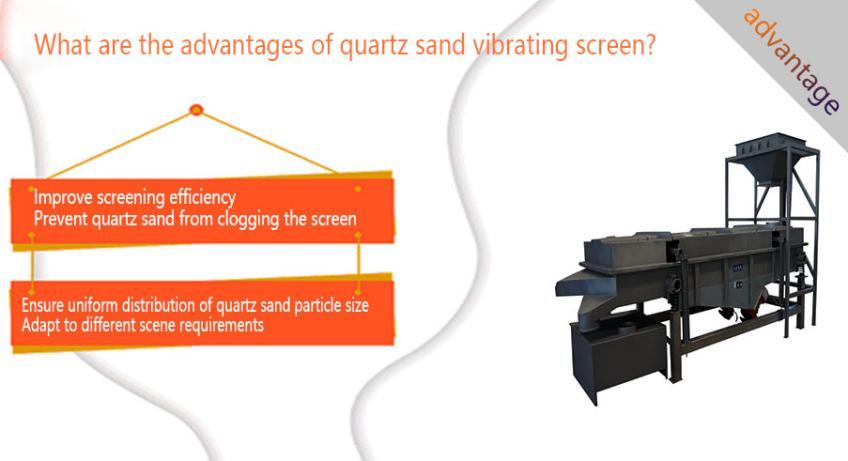

What are the advantages of quartz sand vibrating screen?

1. Improve screening efficiency: The quartz sand vibrating screen can quickly separate particles on the screen through the vibrating screen, accelerate the screening process, and improve screening efficiency. The design and movement of the vibrating screen can effectively divide the particles into different sizes and achieve efficient screening.

2. Prevent quartz sand from clogging the screen: The quartz sand vibrating screen adopts a specially designed screen structure, which can effectively prevent particles from clogging in the screen holes, keep the screen unobstructed, and ensure the screening effect. In addition, the vibration force of the vibrating screen can help particles not easily accumulate and clog during the screening process.

3. Ensure uniform distribution of quartz sand particle size: By adjusting the vibration frequency and amplitude of the vibrating screen, the movement trajectory of the particles on the screen can be controlled to achieve a more uniform particle size distribution. This helps to improve the quality and consistency of quartz sand products.

4. Adapt to different scene requirements: Quartz sand vibrating screens usually have a variety of screen specifications and screen hole sizes to choose from, which can be adjusted and replaced according to different requirements and application scenarios to meet the screening needs of different particle sizes.

Quartz sand vibrating screen mesh

What is the purpose of quartz sand vibrating screen?

Quartz sand vibrating screen is widely used in many fields. In the construction industry, it is used to screen and grade quartz sand to meet the preparation needs of building materials such as concrete and mortar. In the field of glass manufacturing, quartz sand vibrating screen screens out pure quartz sand particles to ensure the quality of glass manufacturing. In addition, it is also used in water treatment, quartz ceramic manufacturing, oil field development and foundry industries, playing an important role in screening and grading, improving production efficiency and product quality.

How do you maintain a quartz sand vibrating screen?

1、Regular calibration: Check the vibration amplitude and frequency of the screen regularly to ensure that they meet the process requirements.

2、Avoid overload operation: Strictly operate according to the rated processing capacity of the equipment to avoid overload operation to avoid damage to the screen or motor.

3、Uniform feeding: Ensure that the material enters the screen evenly to avoid local overload or blockage.

4、Prevent wet material blockage: If the humidity of the quartz sand is too high, it may cause the screen to be blocked. The material can be dried before feeding.

Quartz sand vibrating screen is an energy-saving and customizable screening equipment, which plays an important role in the production and processing of quartz sand. By selecting the appropriate type of vibrating screen and adjusting the relevant parameters, the requirements of different industries for quartz sand particle size and classification can be met. At the same time, quartz sand vibrating screen also has a wide range of application prospects and market demand, and is one of the indispensable important equipment in related industries.

-

Fully sealed structure, no powder overflow, no liquid overflow

-

Remove lumps and debris in flour, improve flour quality

-

For safe sieving and precise grading of liquids, powders and granules, suitable for plants and factories that need to handle large volumes of products

-

For separation of different particle sizes in the same product, safe screening to eliminate foreign matter, solid-liquid separation, etc.

-

Chemical catalyst vibrating screen

Chemical catalyst vibrating screen is a device specially used for screening and grading chemical catalyst...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Standard test sieve

Standard test sieves are precision mesh screens used to separate particles based on size in various industries ...

-

Circular swing screen

Circular swing screen, also known as swing screen or shaking screen, is a low-frequency rotary vibration...

-

Three-dimensional rotary vibrating screen

Three-dimensional rotary vibrating screen, also known as the rotary vibrating screen or the three-dimensional...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.