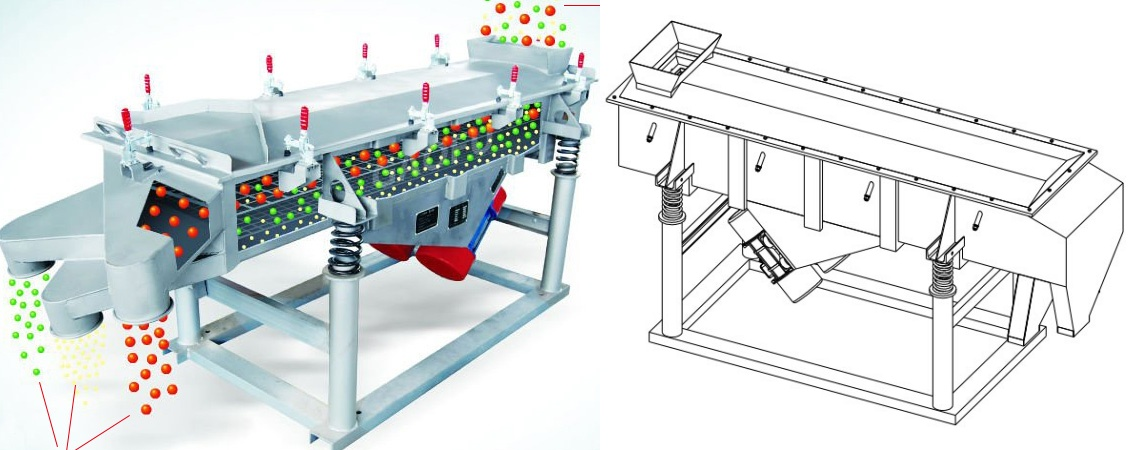

Drying sand vibrating screen

Drying sand vibrating screen is a vibrating screening device specially used for screening dried sand. It is mainly used for screening and grading sand and gravel particles to remove impurities and control the particle size. The dried sand is usually used in the construction, casting, glass and other industries. It separates the dried sand of different particle sizes through the exciting force generated by the vibration motor, making the material on the screen jump, thus realizing the screening and grading equipment, separating the dried sand of different particle sizes to meet different application requirements.

Video of drying sand vibrating screen

What is the principle of drying sand vibrating screen?

Drying sand vibrating screen uses the exciting force generated by the vibration motor to make the drying sand particles on the screen surface jump in the vertical direction and throw in the horizontal direction. Particles smaller than the screen aperture pass through the screen and fall into the discharge port below, while particles larger than the screen aperture are retained on the screen surface and discharged from another discharge port.

The structure of drying sand vibrating screen

Screen frame: usually made of carbon steel or stainless steel, with sufficient strength and rigidity.

Screen: select screens with different apertures and materials according to the screening requirements.

Vibration motor: provides vibration power and is the core component of screening.

Shock absorber: reduces the impact of vibration on the equipment and the surrounding environment.

Feed inlet and discharge outlet: set according to the number of screening layers and particle size requirements.

What are the disadvantages of drying sand vibrating screen?

1. Limited drying effect: The drying effect is affected by the hot air temperature, wind speed and material residence time. If the parameters are not set properly, uneven drying or over-drying may occur. For some special materials, the drying process may destroy the material properties. For some special high-precision screening tasks, the screening accuracy of the drying sand vibrating screen may be limited and cannot meet the needs of all application scenarios.

2. High requirements for material properties: For sand with high viscosity or high water content, the screen is easy to clog, affecting the screening efficiency. If the sand contains impurities (such as soil, organic matter), odor or pollution may be generated during the drying process. The drying sand vibrating screen is suitable for a certain range of particle sizes and characteristics, and may not be suitable for particularly fine or large particles.

3. Operational complexity: The equipment needs to control the screening and drying parameters at the same time, which is difficult to operate and has high technical requirements for operators. If the automatic control system of the drying sand vibrating screen fails, it may affect the entire production process.

4. High energy consumption: The vibration motor of the drying sand vibrating screen needs to consume a lot of electrical energy to maintain high-frequency vibration in order to achieve the screening of the drying sand. Especially for the drying sand vibrating screen with a large processing capacity, its power is relatively large, and long-term operation will incur higher electricity costs.

What is the drying sand vibrating screen used for?

1、Construction materials production: In the production of construction materials, the drying sand vibrating screen is usually used to screen the dried sand, remove impurities and grade it to meet the sand materials of different specifications for the production of concrete, cement products, etc.

2、Glass manufacturing: In the glass manufacturing process, the drying sand vibrating screen is used to screen the sand, remove impurities and control the particle size to produce sand materials that meet the requirements of glass production.

3、Ceramic industry: In the ceramic industry, the drying sand vibrating screen can screen and grade the sand materials to ensure that the quality and particle size of the sand materials meet the production requirements of ceramic products.

4、Foundry industry: In the foundry industry, the drying sand vibrating screen is used to screen the sand materials of the sand mold, remove impurities and control the particle size to improve the surface quality and precision of the castings.

5、Glass fiber manufacturing: In the glass fiber manufacturing process, the drying sand vibrating screen can screen and grade the glass fiber raw materials to ensure that the quality and particle size of the raw materials meet the production requirements.

6、Water treatment: In the field of water treatment, the drying sand vibrating screen can be used to screen and remove sand in the water, purify the water quality, and ensure the normal operation of water treatment equipment.

Drying sand vibrating screen vibrating screen mesh

How to fix a drying sand vibrating screen?

1、Replace the screen: Check the wear of the screen regularly. If there is wear or damage, replace the new screen in time to ensure the screening effect.

2、Repair the vibration mechanism: Check the working status of the vibration mechanism regularly. If abnormal vibration or noise is found, adjust or replace the damaged parts in time.

3、Check the support structure: Check the support structure of the vibrating screen to ensure that the support is stable and avoid shaking or instability of the equipment.

4、Electrical system maintenance: Regularly check the connection lines and electrical components of the electrical system to ensure the normal operation of the electrical equipment.

5、Regular inspection: Regularly carry out comprehensive inspection and maintenance, including checking the various components and connectors of the equipment to ensure the safety and reliability of the equipment.

How do you maintain a drying sand vibrating screen?

Regular cleaning: Clean the screen and screening surface regularly to remove accumulated impurities and particles to avoid blockage and affect the screening effect.

Lubrication and maintenance: Check the lubrication of the vibration mechanism regularly to keep it well lubricated, reduce wear and friction, and extend the life of the equipment.

-

Fully sealed structure, no powder overflow, no liquid overflow

-

Remove lumps and debris in flour, improve flour quality

-

For safe sieving and precise grading of liquids, powders and granules, suitable for plants and factories that need to handle large volumes of products

-

For separation of different particle sizes in the same product, safe screening to eliminate foreign matter, solid-liquid separation, etc.

-

Chemical catalyst vibrating screen

Chemical catalyst vibrating screen is a device specially used for screening and grading chemical catalyst...

-

Powder Vibrating Screen

As an efficient screening equipment, powder Vibrating Screen plays an important role in industrial...

-

Centrifugal screening machine

Centrifugal screening machine is designed and produced for screening problems such as light materials...

-

Standard test sieve

Standard test sieves are precision mesh screens used to separate particles based on size in various industries ...

-

Circular swing screen

Circular swing screen, also known as swing screen or shaking screen, is a low-frequency rotary vibration...

-

Carbon steel straight screen

Carbon steel straight screen is a common screening equipment, usually used in the industrial field to screen...

Email:

sale@xxdahan.com

WhatsApp:

+86 15236742901

Add:

1000m West of Forest Park,Yanjin County,Xinxiang City,Henan Procince,China.